Method for preparing ligustilide

A technology of ligustilide and angelica, applied in the field of extraction and preparation of ligustilide, which can solve the problems of complex process and low purity of ligustilide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The invention compares the effects of different ratios of angelica and chuanxiong and different supercritical extraction conditions on the extraction rate of ligustilide.

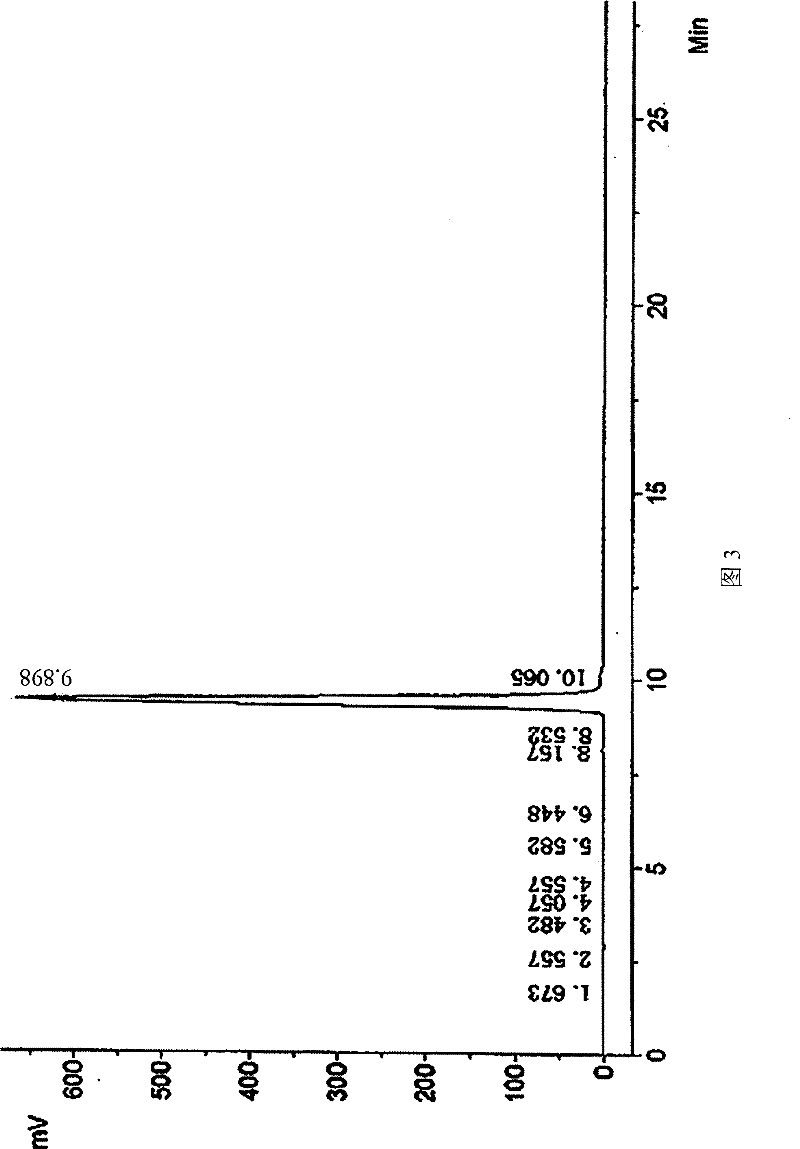

[0023] First, the effects of different ratios of angelica and chuanxiong on the extraction rate of ligustilide were compared. Compared the extraction rate of ligustilide when the mixing ratio of Angelica and Chuanxiong is 5:1~0.2:1, the experiment shows that the mixing ratio of Angelica and Chuanxiong is 0.2:1~ When 1:1, the extraction rate of ligustilide is greater than that of angelica and Chuanxiong when the mixing ratio is 1:1; when the mixing ratio of angelica and Chuanxiong is 0.33:1, the extraction rate of ligustilide highest rate. Experimental data such as figure 1 , Table 1 shows.

[0024] Table 1 Effect of different proportions of angelica and chuanxiong on the content of ligustilide

[0025]

Embodiment 2

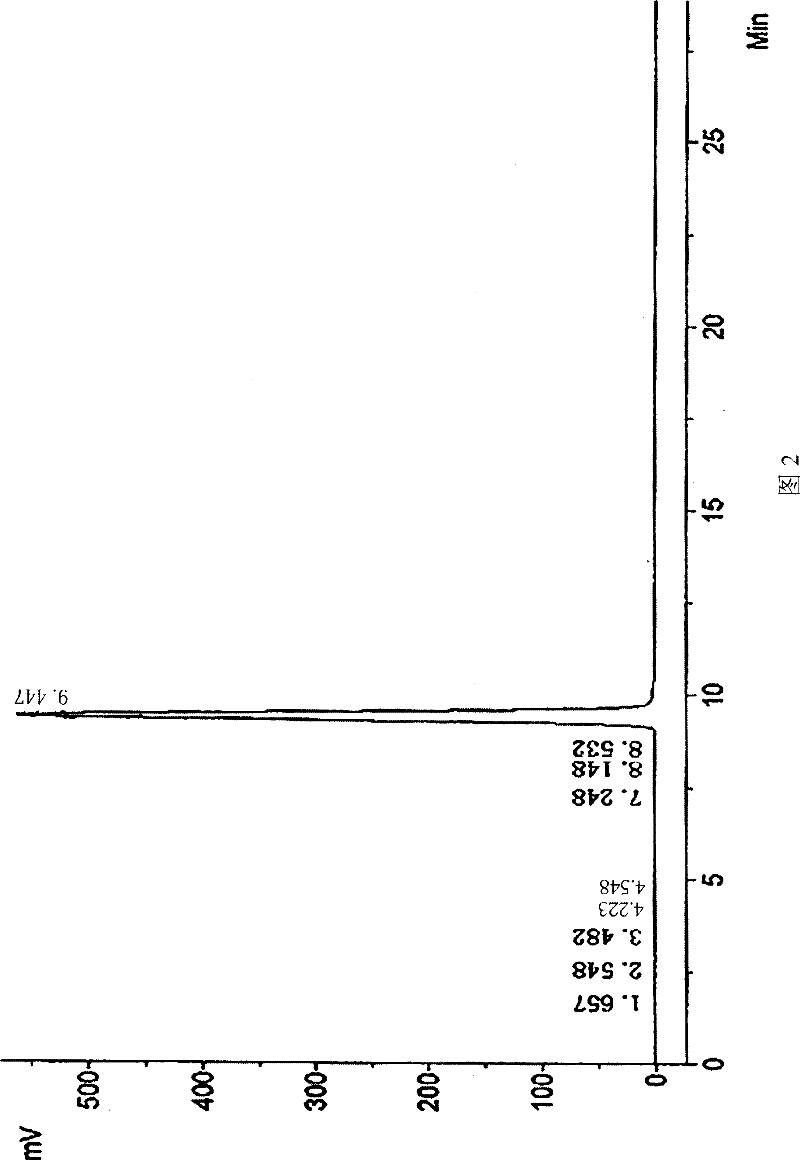

[0027] The present invention compares the influence of different supercritical extraction conditions on the extraction rate of ligustilide. Orthogonal experiments were used to investigate the extraction temperature, extraction pressure, CO 2 The influence of four factors of flow rate and extraction time on the extraction rate of ligustilide, the experiment shows that the optimal conditions for supercritical extraction of ligustilide are: extraction temperature is 50°C, extraction pressure is 30MPa, CO 2 The flow rate is 30L / h, and the extraction time is 2.0h. The experimental data are shown in Table 2.

[0028] Table 2 Effect of different supercritical extraction conditions on the content of ligustilide

[0029]

[0030]

[0031] The mixing ratio of Angelica sinensis and Rhizoma Chuanxiong adopted in the present invention is 0.2:1~1:1 and the extraction rate of the ligustilide extracted under supercritical extraction conditions is higher than that of the prior art, and...

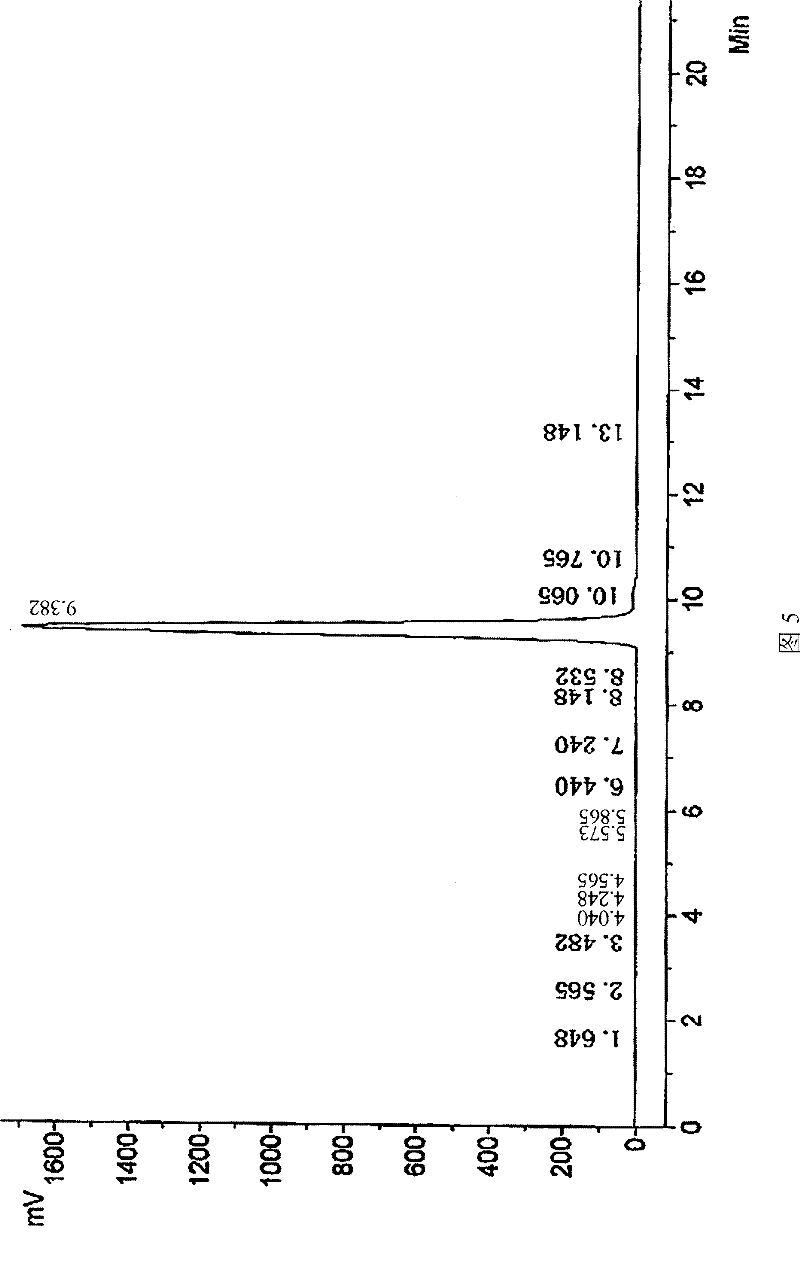

Embodiment 3

[0033] Put 200 g of the mixed medicinal material (0.33:1) powder (40 mesh) of Angelica sinensis and Rhizoma Chuanxiong into a 1L extraction kettle, and use supercritical CO 2 Do the extraction. The temperature of the extraction tank is 50°C and the pressure is 30MPa; the temperature of the separation tank I is 50°C and the pressure is 8MPa; the temperature of the separation tank II is 30°C and the pressure is 6MPa; 2 The flow rate is 30L / h; the extraction time is 2.0h. An extract rich in ligustilide was obtained, and the extraction rate of ligustilide was 3.23%.

[0034] Put the above extract on a medium-pressure silica gel column, and elute with petroleum ether (30-60°C)-diethyl ether (99:1) at a low temperature of 10°C and in the dark, and collect 250ml as a fraction, which is analyzed by TLC. After thin-layer chromatography inspection, HPLC determination, combined pure fractions, recovered solvent under reduced pressure at 30°C, transferred to a small bottle with ether, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com