Rotating switch

A technology of rotary switch and switch frame, which is applied to electric switches, the arrangement of accessories on instrument panels, electrical components, etc., can solve the problem of not getting knocking feeling, and achieve assembly man-hours, improve angular accuracy, and fit strength. unifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

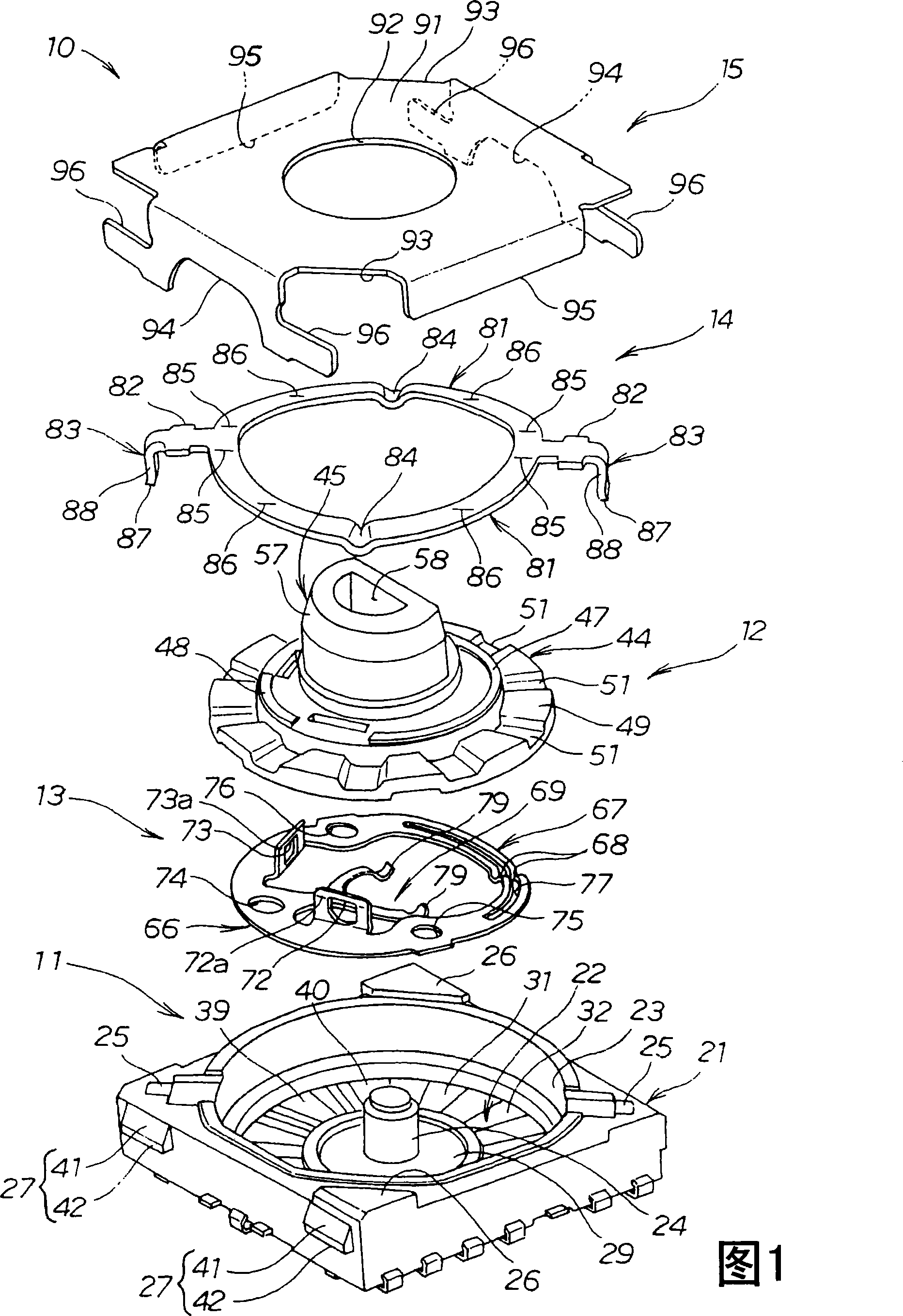

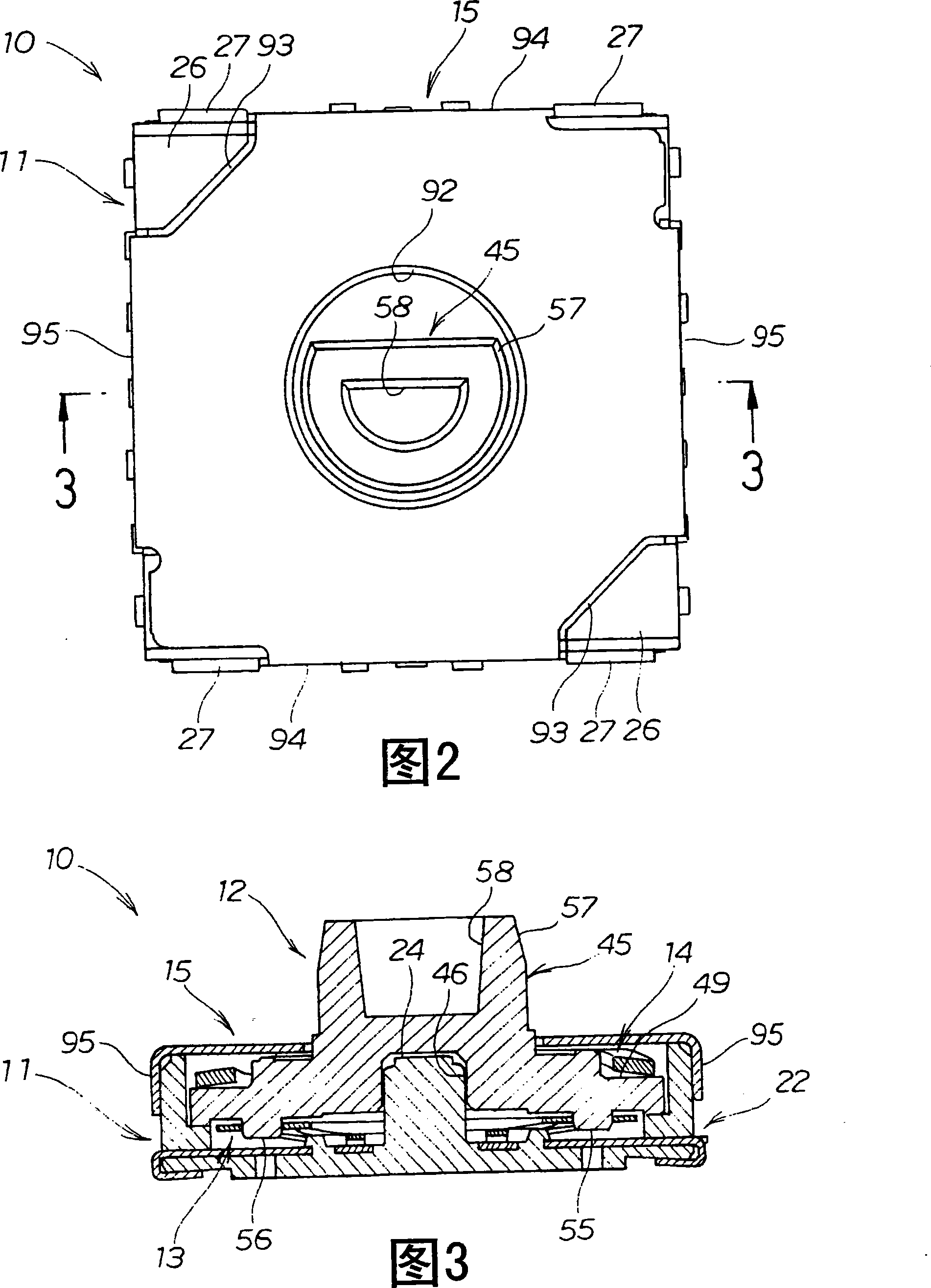

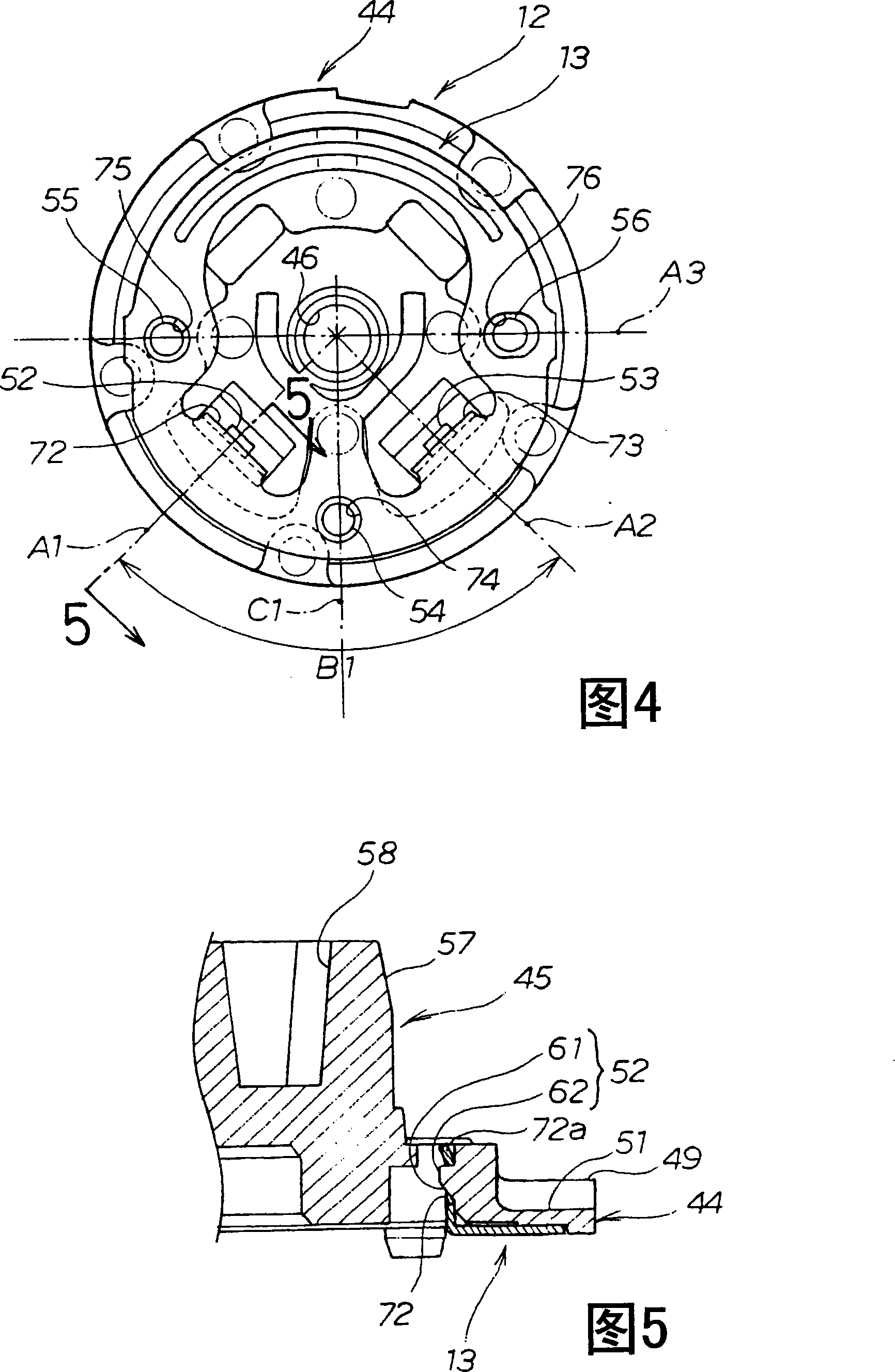

[0040] Hereinafter, embodiments of the present invention will be described in detail according to the accompanying drawings.

[0041] As shown in Fig. 1, Fig. 2 and Fig. 3, the rotary switch 10 is composed of the following components: a substantially square switch frame 11; a rotary operation knob 12 rotatably installed on the switch frame 11; The contact piece 13 on 12; the leaf spring 14 engaged on the switch frame 11; the cover 15 covering the switch frame 11.

[0042]The switch frame 11 is made up of the following parts: a frame body 21 made of insulating material; a fixed contact 22 provided on the frame body 21; in order to expose the sliding part of the fixed contact 22 of the contact piece 13 sliding, the frame body The receiving recess 23 provided on 21; the cylindrical support shaft 24 provided in the approximate center of the receiving recess 23; the engaging parts (press-fit grooves) 25, 25 provided on the two opposite corners of the frame main body 21; The two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com