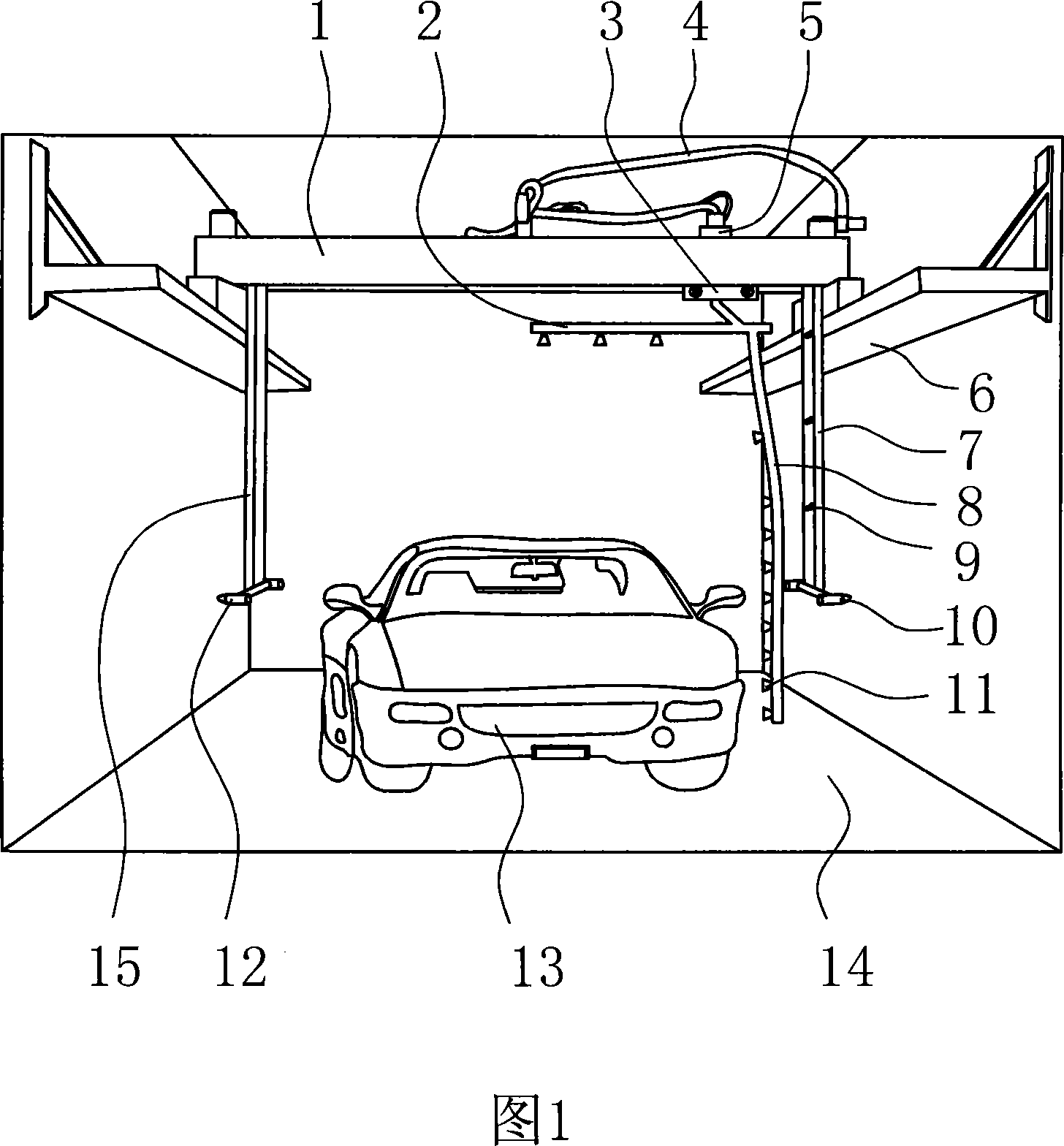

Surrounding type non-contact wiping-free car washing machine

A wiping-free, car-washing technology, which is applied to the vehicle exterior cleaning device and other directions, can solve the problem of not being able to detect the width of the vehicle body, and achieve the effect of accurate spray position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

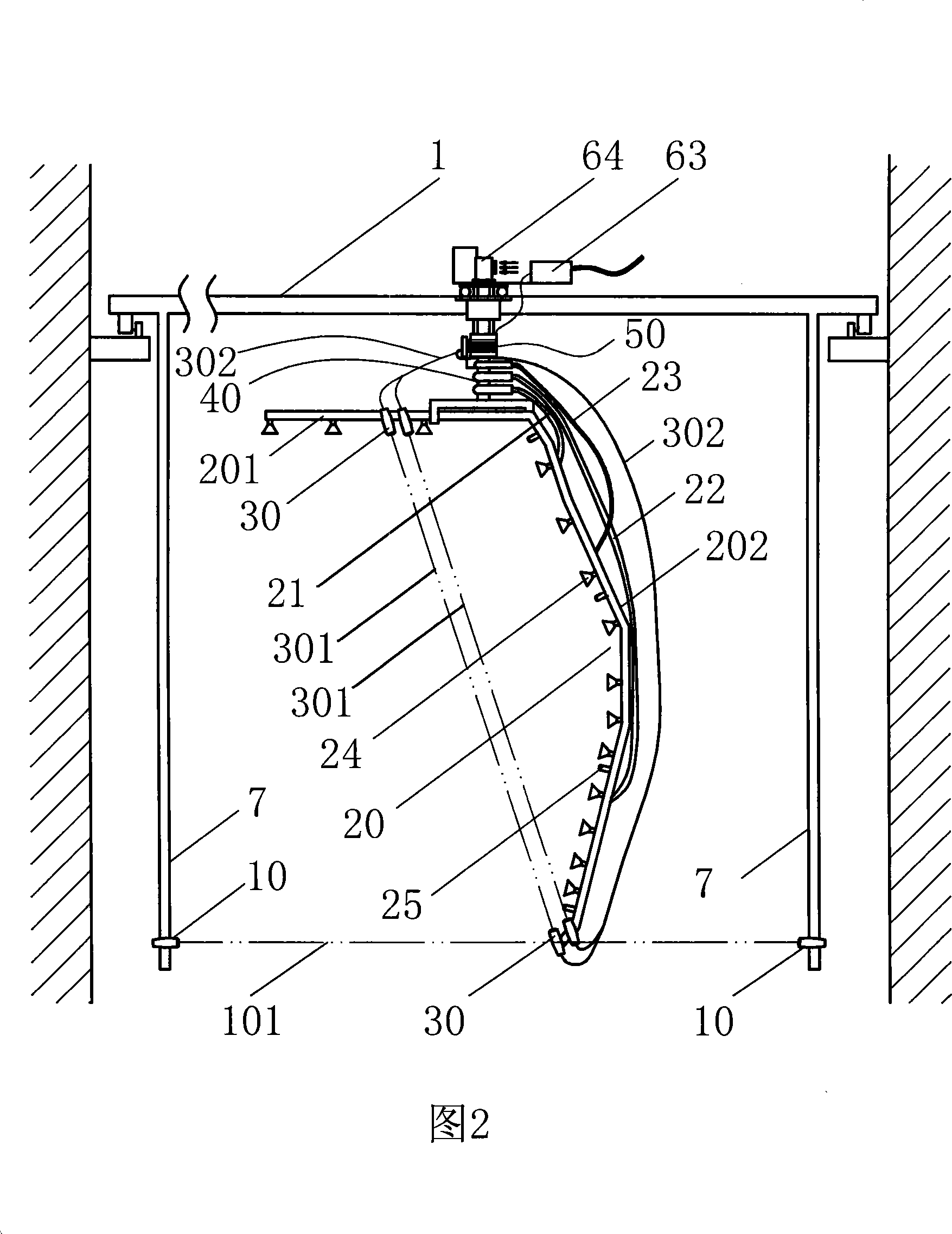

Embodiment 1

[0023] Embodiment 1: Refer to Fig. 2, Fig. 4-7: Surrounding type non-contact and wipe-free car washing machine, including two pairs of infrared electronic anti-radiation probes 10 and The bow-shaped liquid spraying frame 20 composed of the top liquid spraying rod 201 and the liquid spraying side rod 202 is provided with a water nozzle 24 on the liquid spraying frame 20, and the liquid spraying frame 20 can be moved longitudinally and laterally under the drive of the motor. The longitudinal axis of the liquid spray frame is rotated 360 degrees, and at the middle part of the top liquid spray rod 201 and the lower end of the liquid spray side rod 202, two pairs of infrared electronic probes 30 that can transmit and receive signals are installed respectively. When the shooting probe 30 shoots against each other, two detection lines 301 separated by a certain distance can be formed in the plane formed by the bow-shaped liquid spray frame 20. The signal line of the infrared electroni...

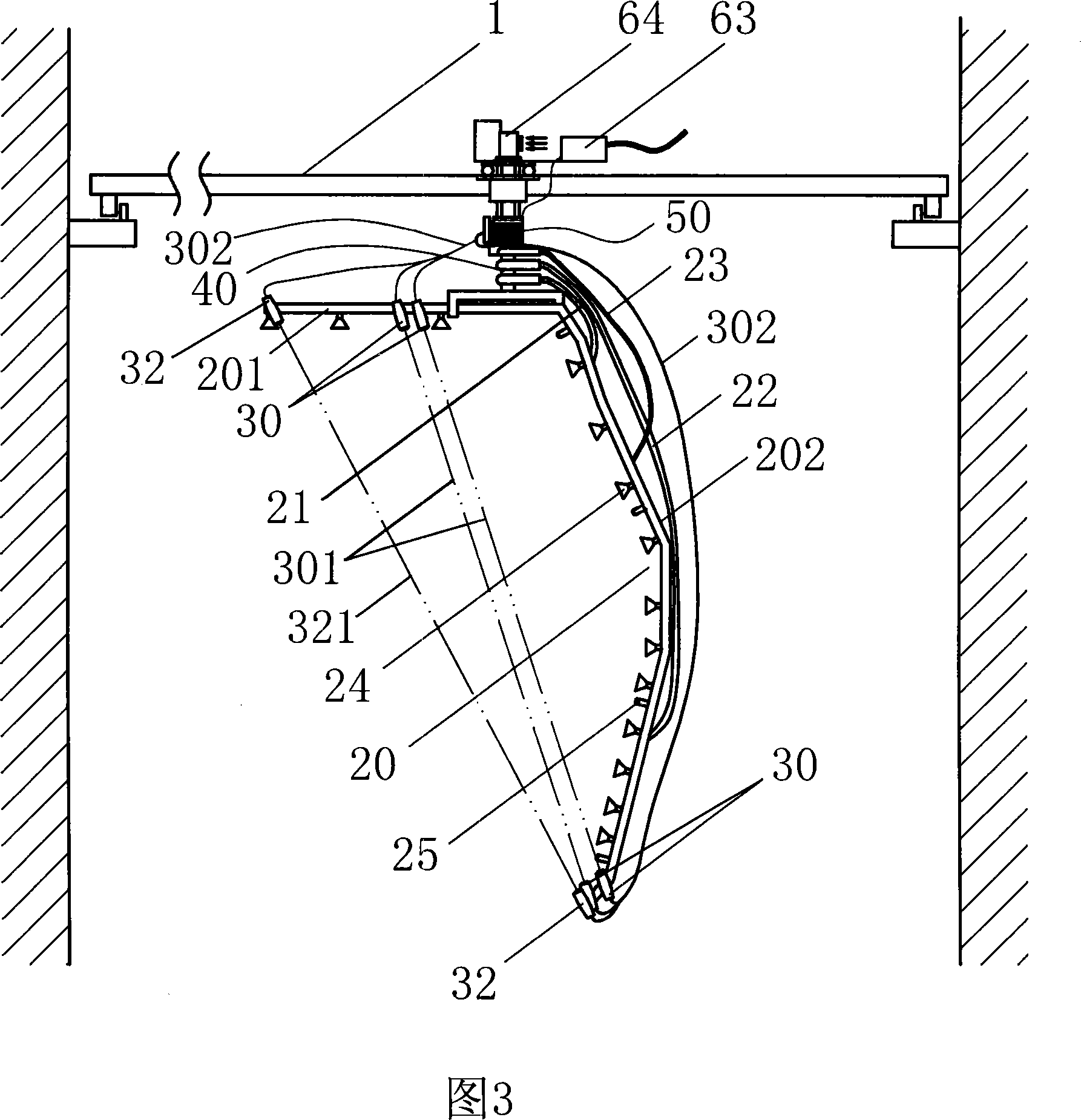

Embodiment 2

[0026] Embodiment 2: Refer to Fig. 3, Fig. 4-7: the basic structure is the same as that of Embodiment 1, the difference is that: the two hangers 7 lower ends of the two suspension frames 7 that are installed on the two ends of the crossbeam 1 and hang down as described in Embodiment 1 A pair of infrared electronic shooting probes 32 arranged at the two ends of the spray frame 20 replace the infrared electronic shooting probe 10, and the detection line 321 formed by a pair of infrared electronic shooting probes 32 is responsible for detecting the front and the rear of the vehicle. And the detection signal is sent to the PLC programmable controller so as to control the rotation of the liquid spray frame 20, and spray liquid to clean the front and rear of the vehicle.

[0027] Working process and principle of the present invention:

[0028] 1. When the vehicle enters the car wash room, under the control of the PLC programmable controller, the water wall formed by the water nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com