Tool bit effective machining area calculation based on three scan line and cutter path creation method

A tool path and processing area technology, which is applied in the field of effective processing area calculation and tool path generation based on three-scanning lines, can solve the problem that the tool path is not well resolved, and achieve the effect of improving calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

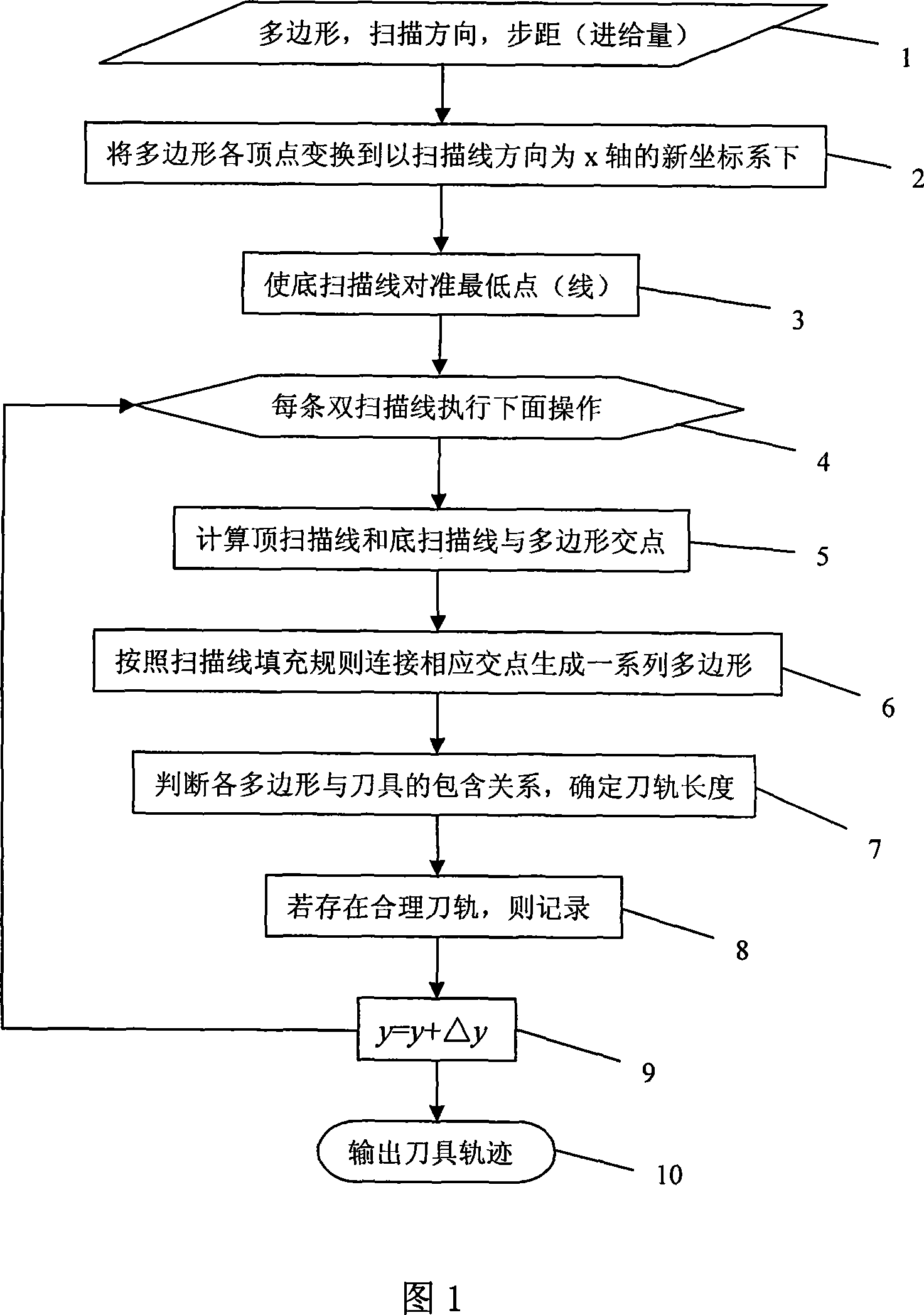

[0026] Figure 1 is a flowchart of the optimal tool path generation based on the three-scanning line method. Referring to the flowchart, the process of generating the optimal tool path is described as follows:

[0027] Step 1, determine polygon, scanning direction, step distance (feed amount).

[0028] In step 2, each vertex of the polygon is transformed into a new coordinate system with the scanning line direction as the x-axis.

[0029] Step 3, align the bottom scan line of the scan line with the lowest point (line) of the polygon.

[0030] Step 4, each double scan line (top scan line and bottom scan line) executes step 5 to step 9 loop operation until there is a reasonable tool path.

[0031] Step 5, calculate the intersection point of the two straight lines and the polygon, use the topological relationship to determine the corresponding edge sets, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com