Method for forming multi-layer coating film

A multi-layer coating film and coating technology, applied in coating, electrophoretic coating, electrolytic coating, etc., can solve problems such as difficult combination, instability of mixed solution, coating efficiency, negative impact on corrosion resistance and appearance, and achieve Remarkable technical effect, excellent corrosion resistance, and shortened cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

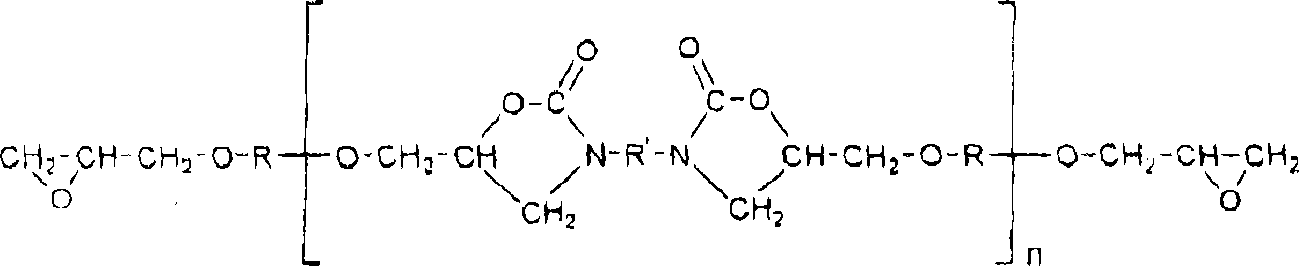

[0093] Preparation Example 1 (Preparation of Base Resin (B) with Cationic Groups)

[0094] A reaction vessel equipped with a stirrer, a decanter, a nitrogen gas introduction tube, a thermometer and a dropping funnel, into which bisphenol A epoxy resin having an epoxy value of 188 (trademark "DER-331J", manufactured by DOW Chemical Company) was charged 2400 parts, methanol 141 parts, methyl isobutyl copper 168 parts and dibutyltin dilaurate 0.5 parts, the mixture was stirred at 40°C until uniformly dissolved. Then 320 parts of 2,4- / 2,6-toluene diisocyanate (a mixture of 80 / 20 by weight) was added dropwise over 30 minutes to raise the temperature to 70°C, and 5 parts of N,N-dimethyl benzylamine to raise the system temperature to 120°C. The reaction was continued at 120°C for 3 hours while methanol was being distilled off until the epoxy value reached 232. After adding 644 parts of methyl isobutyl copper, 341 parts of bisphenol A, and 413 parts of 2-ethylhexanoic acid, the re...

preparation Embodiment 2

[0095] Preparation Example 2 (preparation of curing agent (C))

[0096] A reaction vessel, equipped with a stirrer, a nitrogen introduction tube, a condenser and a thermometer, added 222 parts of isophorone diisocyanate, diluted with 56 parts of methyl isobutyl ketone, and then added 0.2 parts of lauric acid Butyltin, raise its temperature to 50°C. Then, 17 parts of methyl ethyl ketone oxime was added to the mixture and the temperature of the material did not exceed 70°C. The reaction mixture was kept at 70°C for 1 hour until the absorption substantially disappeared as confirmed by infrared absorption spectroscopy. Then, the reaction mixture was diluted with 43 parts of n-butanol to obtain the target blocked isocyanate curing agent solution (solid content 70%).

preparation Embodiment 3

[0097] Preparation Example 3 (Preparation of Pigment Dispersion Resin)

[0098] A reaction vessel, equipped with a stirrer, a condenser, a nitrogen gas introduction tube and a thermometer, was charged with 710 parts of bisphenol A epoxy resin (trademark "Epon 829", manufactured by Shell Chemicals Ltd) with an epoxy value of 198 and 289.6 parts of bisphenol A , the reaction was carried out at 150 to 160° C. for 1 hour in a nitrogen atmosphere. After cooling the reaction mixture to 120° C., 406.4 parts of a methyl isobutyl ketone solution (solid content 95%) of toluene diisocyanate half-blocked with 2-ethylhexanol was added thereto. The reaction mixture was kept at 110 to 120°C for 1 hour, then 1584.1 parts of ethylene glycol mono-n-butyl ether were added, the mixture was cooled to 85 to 95°C and homogenized.

[0099] Separate from the preparation of the above-mentioned reaction product, a mixture of 384 parts of toluene diisocyanate in methyl isobutyl ketone (solid content 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com