Method for obtaining enhanced fatigue strength in welded metal joints and hammer head for use at cold working

A welding metal, fatigue strength technology, applied in the field of hammerheads used in welded metal joints to obtain enhanced fatigue strength and cold working, can solve problems such as fatigue life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

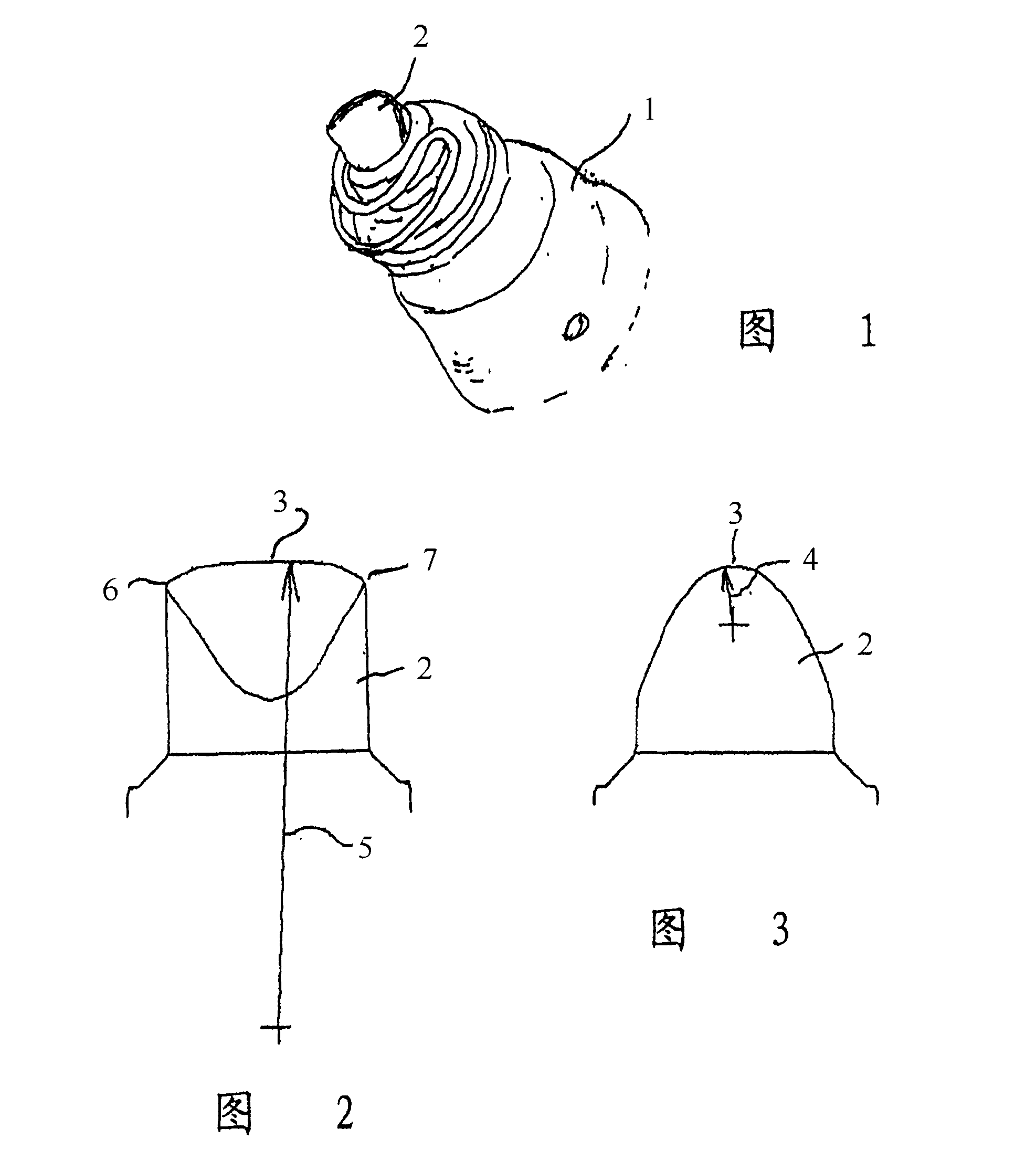

[0031] Figure 1 shows a part of a pneumatic hammer 1 having a hammer head 2 according to an embodiment of the invention.

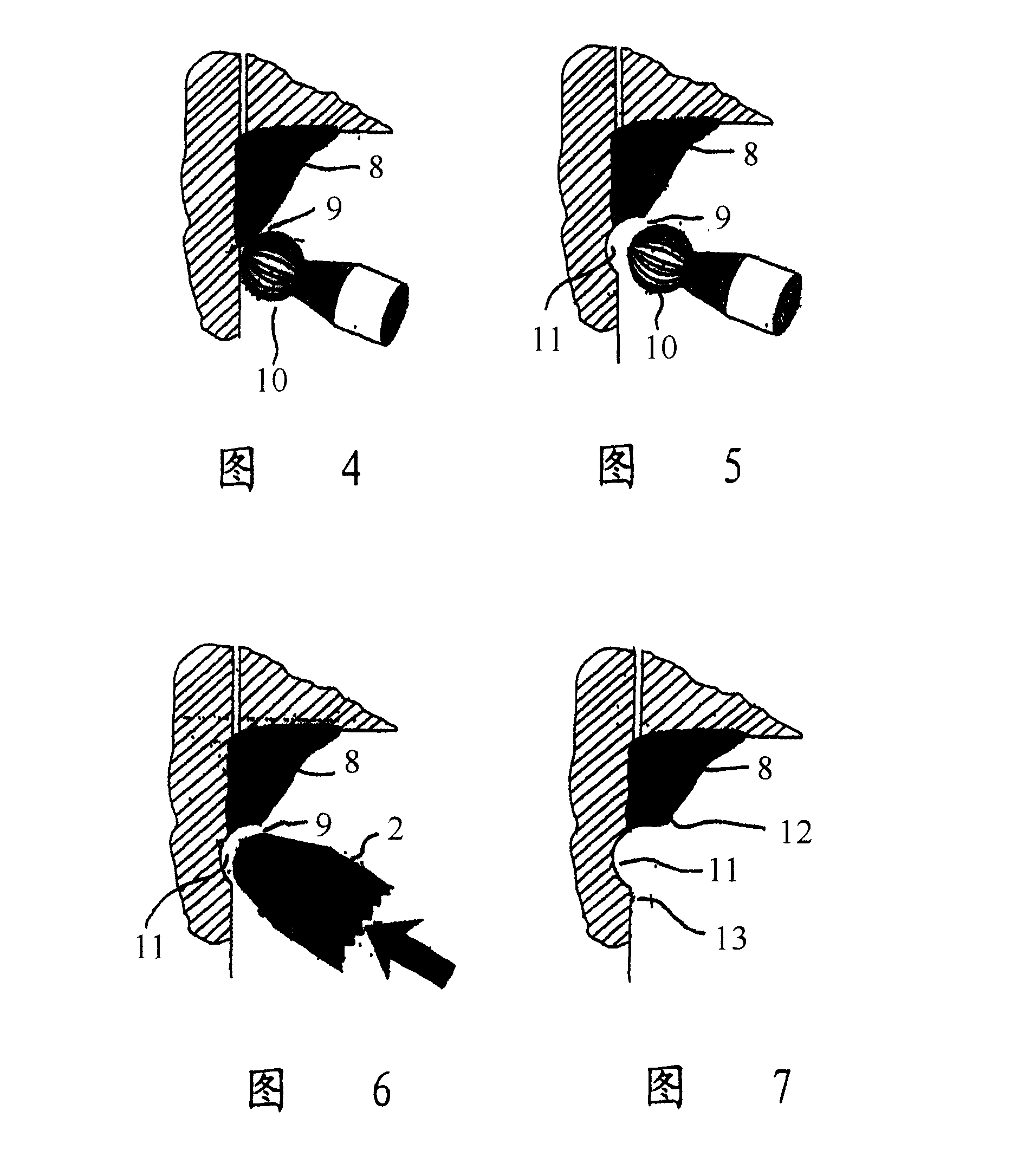

[0032] The hammer head 2 is shown in more detail in FIGS. 2 and 3 . The striker 2 is characterized in that it has a slightly convex, elongated contact area or surface 3 , here in the transverse direction with a radius 4 which is smaller than the radius 5 in the length direction. The contact surface for the hammer head against the weld toe (9 in Figure 4) has a smooth rounded shape at each end 6,7. As shown in Figures 2 and 3, the radius 5 of the hammer head in the length direction is greater than twice the radius 4 of the hammer head in the transverse direction, and less than 20 times the radius 4 in the transverse direction. The figures presented here define the preferred ranges. Although not shown in the figures, the contact surface for the peen against the weld toe is advantageously ground to a surface finish of better than Ra 1.2.

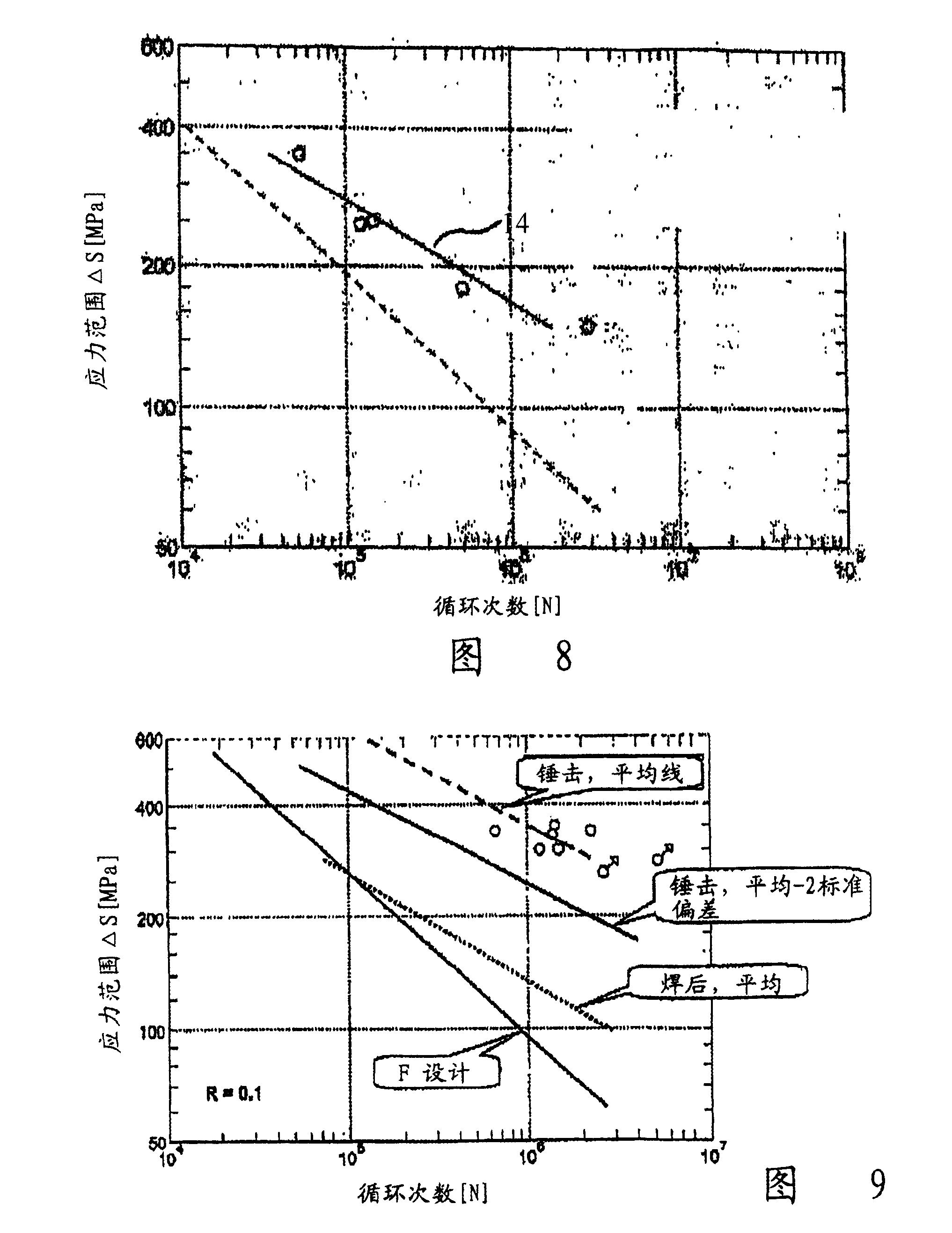

[0033] FIG. 4 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com