Modular system for a sliding or pop-up roof for vehicle roofs and method for producing such a sliding or pop-up roof

A sliding and lifting technology, which is applied to vehicle components, roofs, transportation and packaging, etc., can solve the problem of high manufacturing cost of sliding sunroofs and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

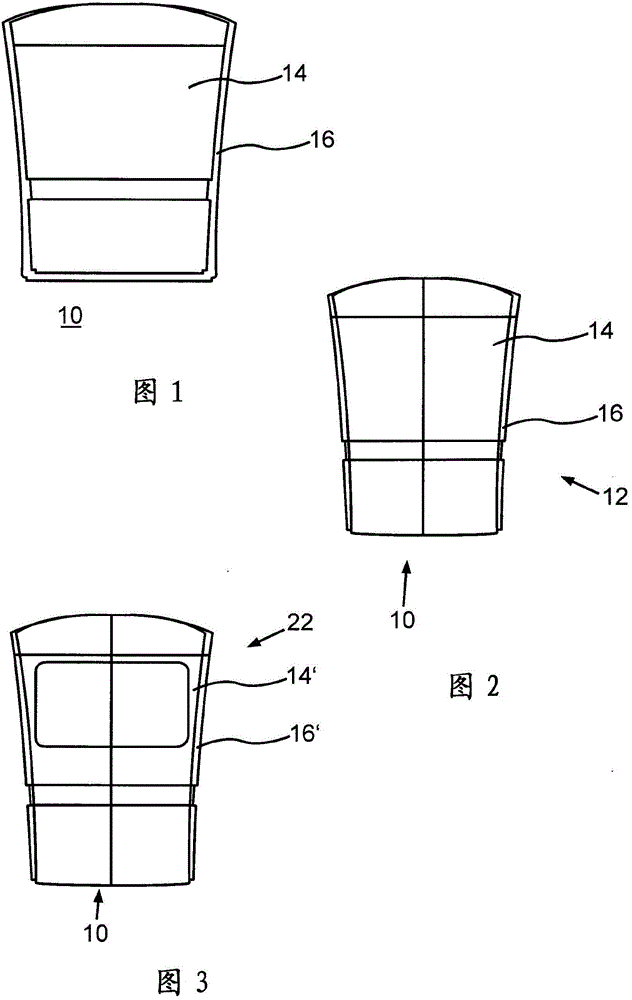

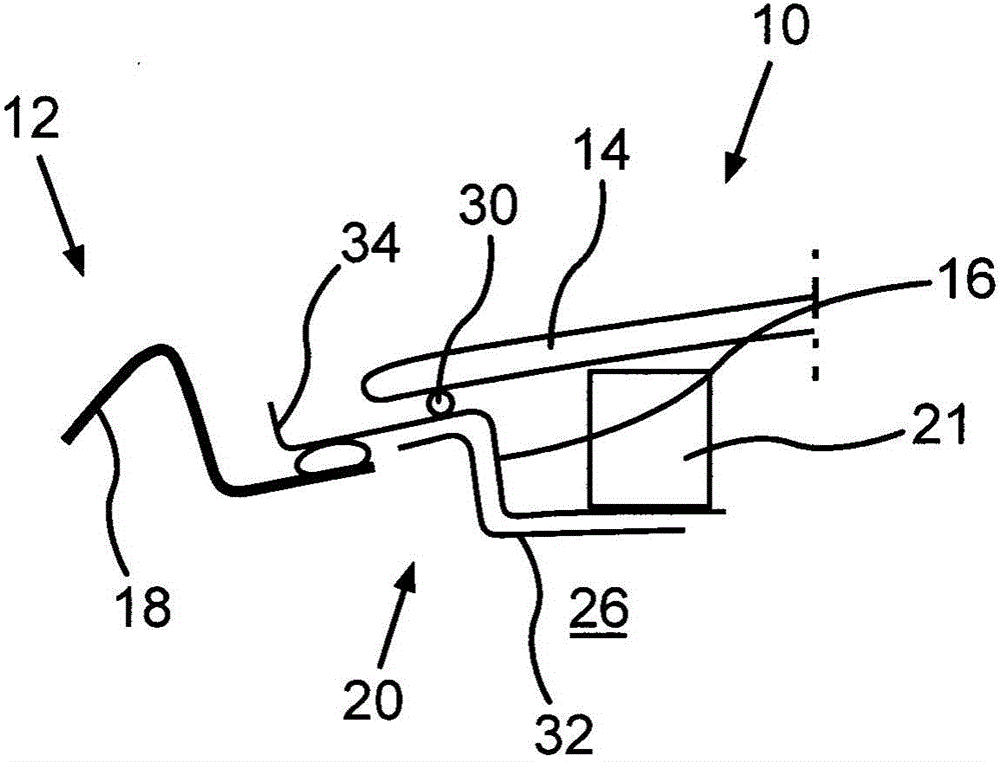

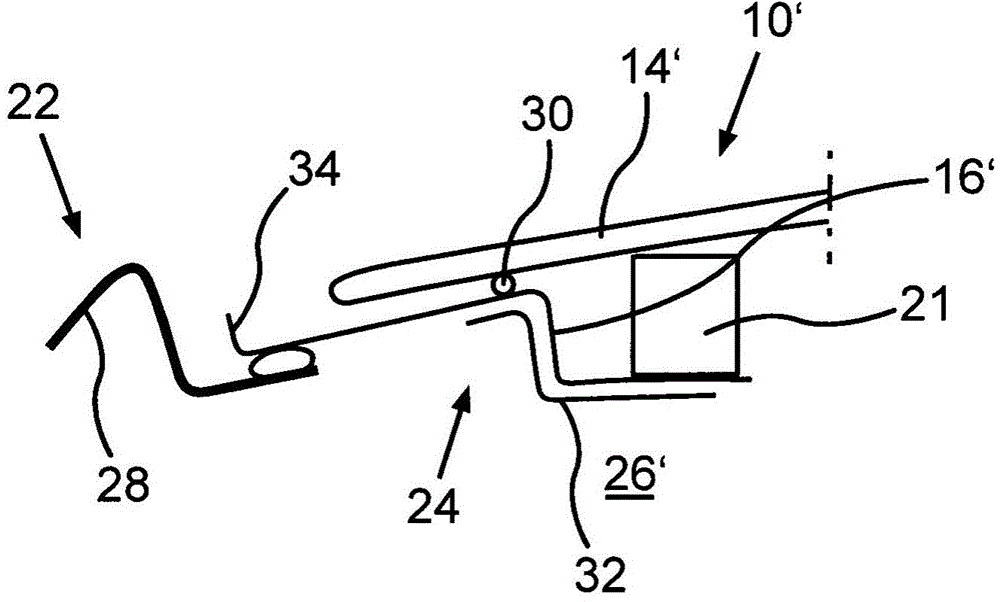

[0028] figure 1 A first vehicle roof 12 ( figure 2 ) of the so-called external sliding sunroof 10 . The outer sliding sunroof 10 comprises a first covering element 14 and a first frame element 16 . combine Figure 4 and 5 It can be seen that the first frame element 16 can be fastened to the frame structure 18 on which the first vehicle roof 12 is formed. The first frame element 16 serves to hold the first cover element 14 . Thus, the first covering element 14 is fastened to the vehicle frame structure 18 via the first frame element 16 .

[0029] In this case, the first cover element 14 can be positioned relative to the first frame element 16 in a closed position which closes the first roof opening 20 of the first vehicle roof 12 and at least one of which at least partially locks the first roof opening 20 . The released open position is moved generally in the longitudinal direction of the vehicle. Top cover driver 21 ( Figure 4 and 5 ) and the motion system are used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com