Hydrogen sensor, preparation method thereof, and method for realizing hydrogen detection

A sensor, hydrogen technology, applied in the field of sensors, can solve problems such as weakening optical response, and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

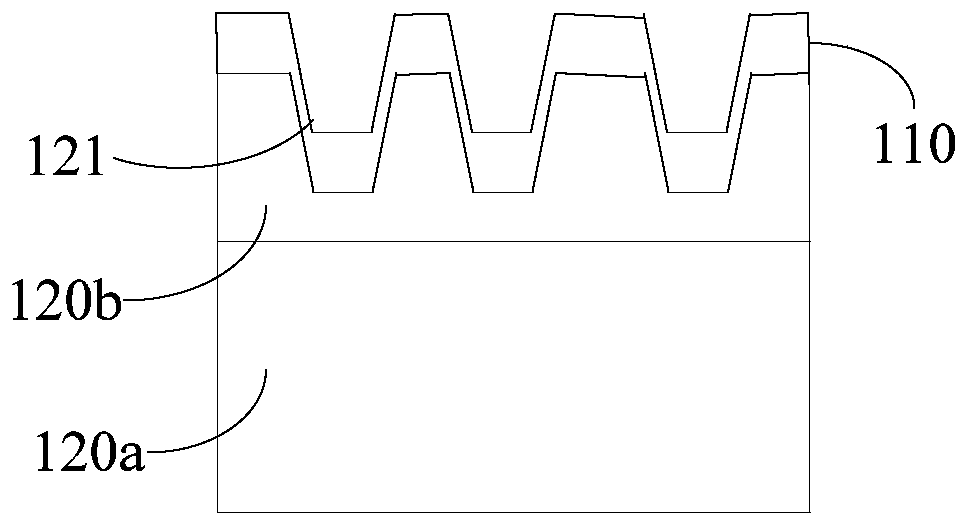

[0060] Such as Figure 4 As shown, the preparation method of the above-mentioned hydrogen sensor of an embodiment comprises the following steps:

[0061] S1: Formation of an adhesive film on a rigid substrate.

[0062] Specifically, a layer of adhesive film 140 is formed on the rigid substrate 130 by spin coating, such as Figure 5 shown. Wherein, the rigid substrate 130 may be a transparent rigid substrate such as quartz. The adhesive film 140 may be a polymethyl methacrylate film, a polyethylene film, or a polypropylene film. The adhesive film 140 is convenient for the subsequent formation of the photoresist layer, and the thickness of the adhesive film 140 may be 30nm-200nm.

[0063] S2: Under darkroom conditions, a photoresist layer is formed on the adhesive film.

[0064] Specifically, such as Image 6 As shown, a photoresist layer 150 is formed on the adhesive film 140 by spin coating. The photoresist layer 150 may have a thickness of 80nm-600nm. Wherein, the pho...

Embodiment 1

[0103] (1) At room temperature, under darkroom conditions, spin-coat polymethyl methacrylate film and photoresist film successively on a clean quartz substrate; wherein, the thickness of polymethyl methacrylate film is 50nm, photoresist The thickness of the film is 90nm;

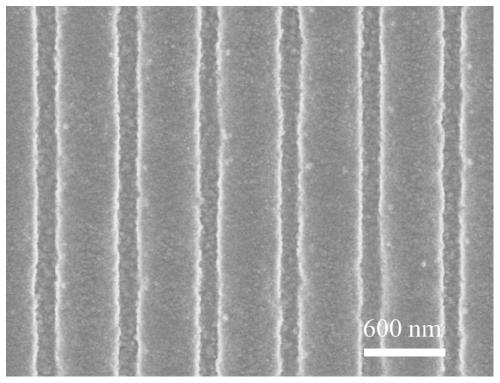

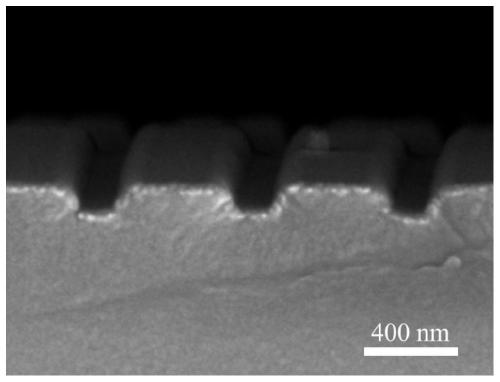

[0104] (2) Carry out double-beam exposure and development to the photoresist, so that the photoresist layer has a nano-grating structure; wherein, the conditions for performing double-beam exposure and development are: the incident angle of the double-beam is 34.9 degrees, and the exposure time is 50 seconds, the developing time is 60 seconds, and the developing temperature is 21 degrees;

[0105] (3) Put the treated photoresist and the release agent perfluorooctyltrichlorosilane together into a vacuum dish, vacuumize, and after standing for 40 minutes, the release agent molecules volatilize and cover the photoresist template;

[0106] (4) Add 3.4g of methylvinyldimethyl (siloxane and polysiloxane), 100mg o...

Embodiment 2

[0114]The hydrogen sensor was prepared according to the steps of Example 1, except that the size parameters of the nano-grating structure were: the period was 1000 nm, the groove depth was 90 nm, the groove opening width was 370 nm, and the groove bottom width was 240 nm.

[0115] The hydrogen sensor prepared in Example 2 was put into a gas flow cell, fed with pure nitrogen, and its reflectance spectrum was measured with a UV-Vis-Near-Infrared Spectrophotometer (Lambda 950, PerkinElmer). Pass into 4% hydrogen (the mixed gas of hydrogen and nitrogen, the volume ratio of hydrogen and nitrogen is 4:96) then, adopt ultraviolet-visible-near-infrared spectrophotometer (Lambda950, PerkinElmer) to measure its reflection spectrum, measurement result is as follows Figure 12 shown. According to the reflectance spectrum measurement and calibration method in Example 1, it is measured that the resonance wavelength has shifted by 28nm, and the full width at half maximum of the resonance is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com