Torque Transmission Mechanism

A technology of torque transmission mechanism and starting torque, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., and can solve problems such as increasing sealing gaskets and lubricant leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

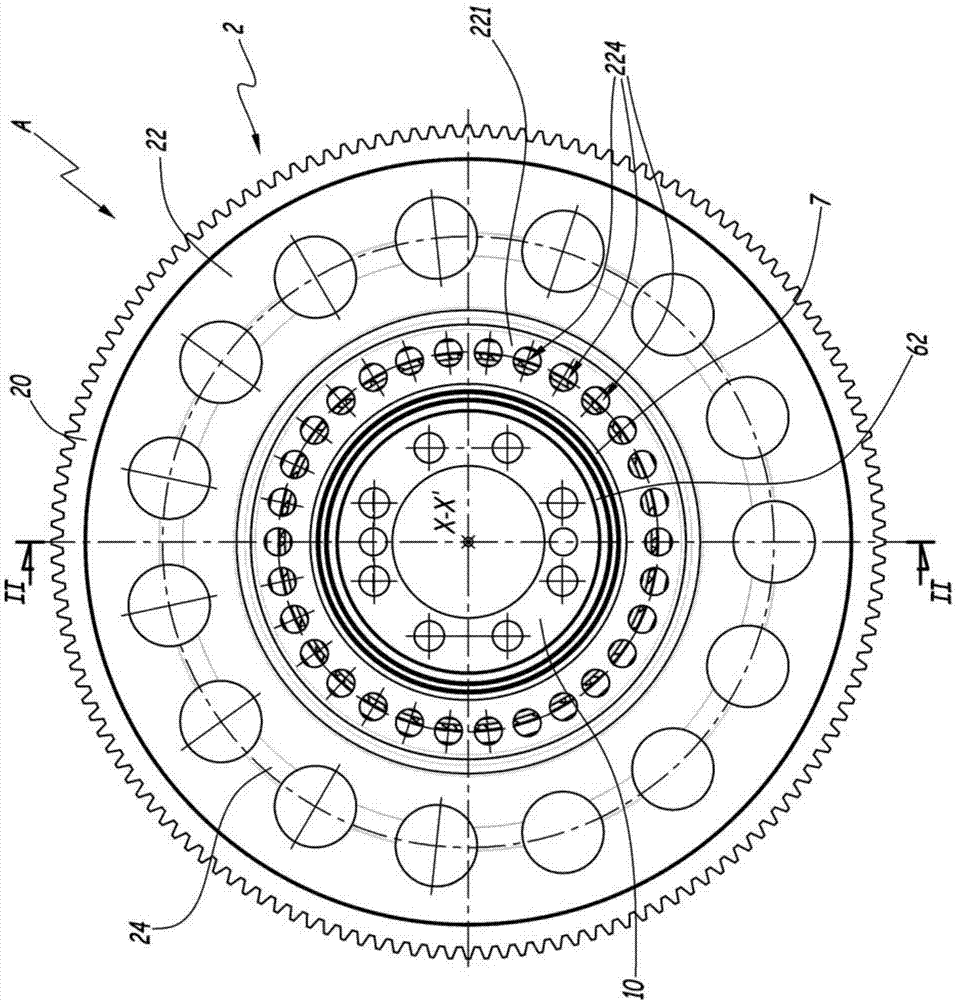

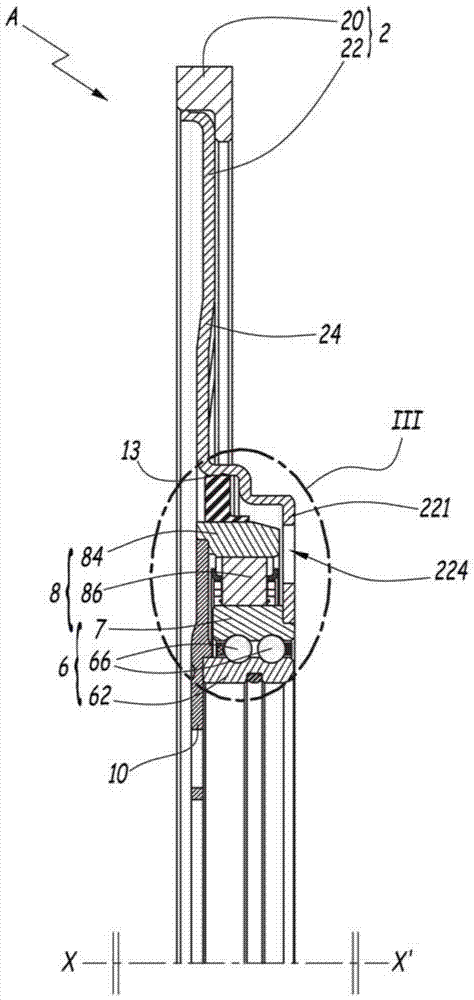

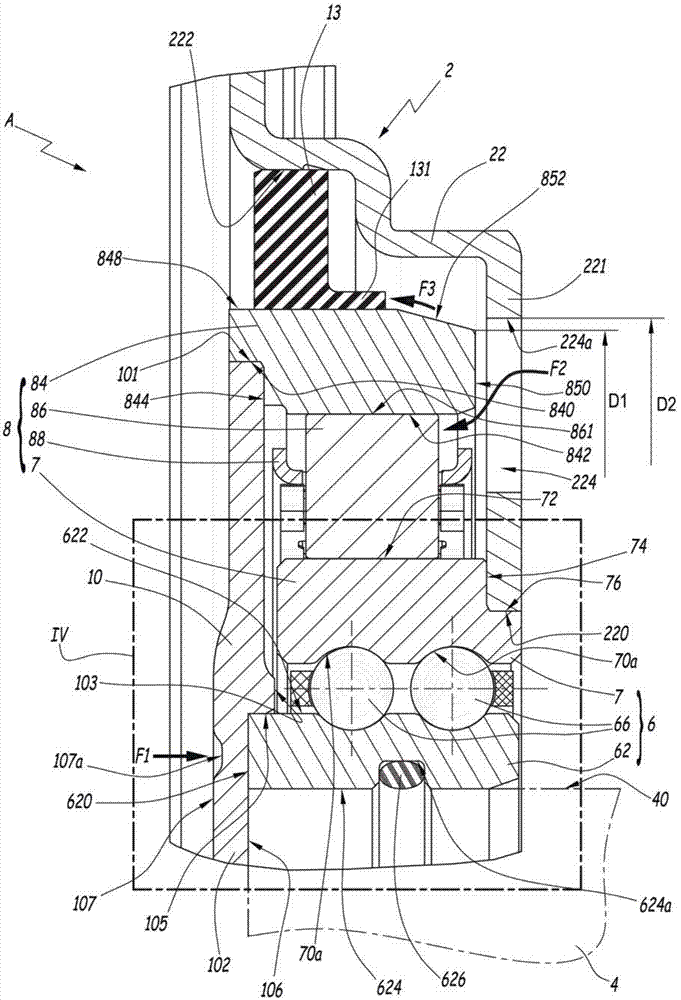

[0022] pictured in Figures 1 to 7 The torque-transmitting mechanism A in includes a ring gear 2 driven by a not-shown pinion of a not-shown starter motor. The ring gear 2 is rotatable relative to a crankshaft 4 of a not shown internal combustion engine. For simplicity and clarity, axis 4 is only in image 3 and 4 Shown above with a dotted line. The rotation of the ring gear 2 relative to the crankshaft 4 is allowed by means of a rolling bearing 6 comprising an inner ring 62 adapted to receive the crankshaft 4 and connected in rotation with it; Two raceways 70a, the tubular portion 7 is rotationally connected with the ring gear 2; and rolling elements, such as balls 66, between the inner ring 62 and the raceway 70a.

[0023] The torque transmitting mechanism A also includes a one-way clutch 8 comprising an inner ring formed by the outer surface 72 of the tubular portion 7, an outer ring 84 and mounted in a cage 88 between the inner ring 82 and the outer surface 72. Wedge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com