Suction cup type knife sharpener

A knife sharpener and sucker-type technology, which is applied in grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc., can solve the problems of inability to position, inability to grind the blade, inconvenient use, etc., and achieve the goal of using Safe and convenient, good grinding effect, easy to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

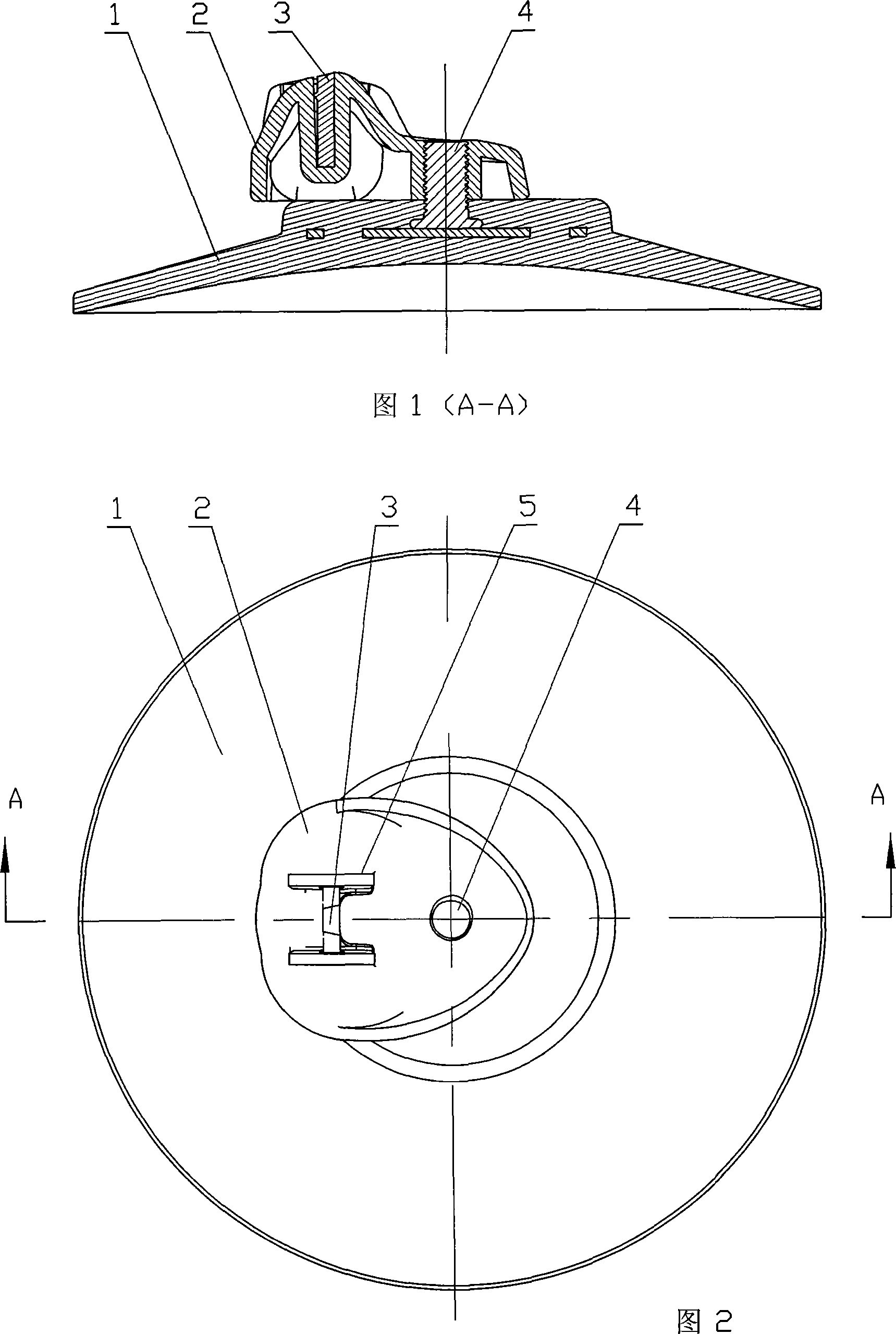

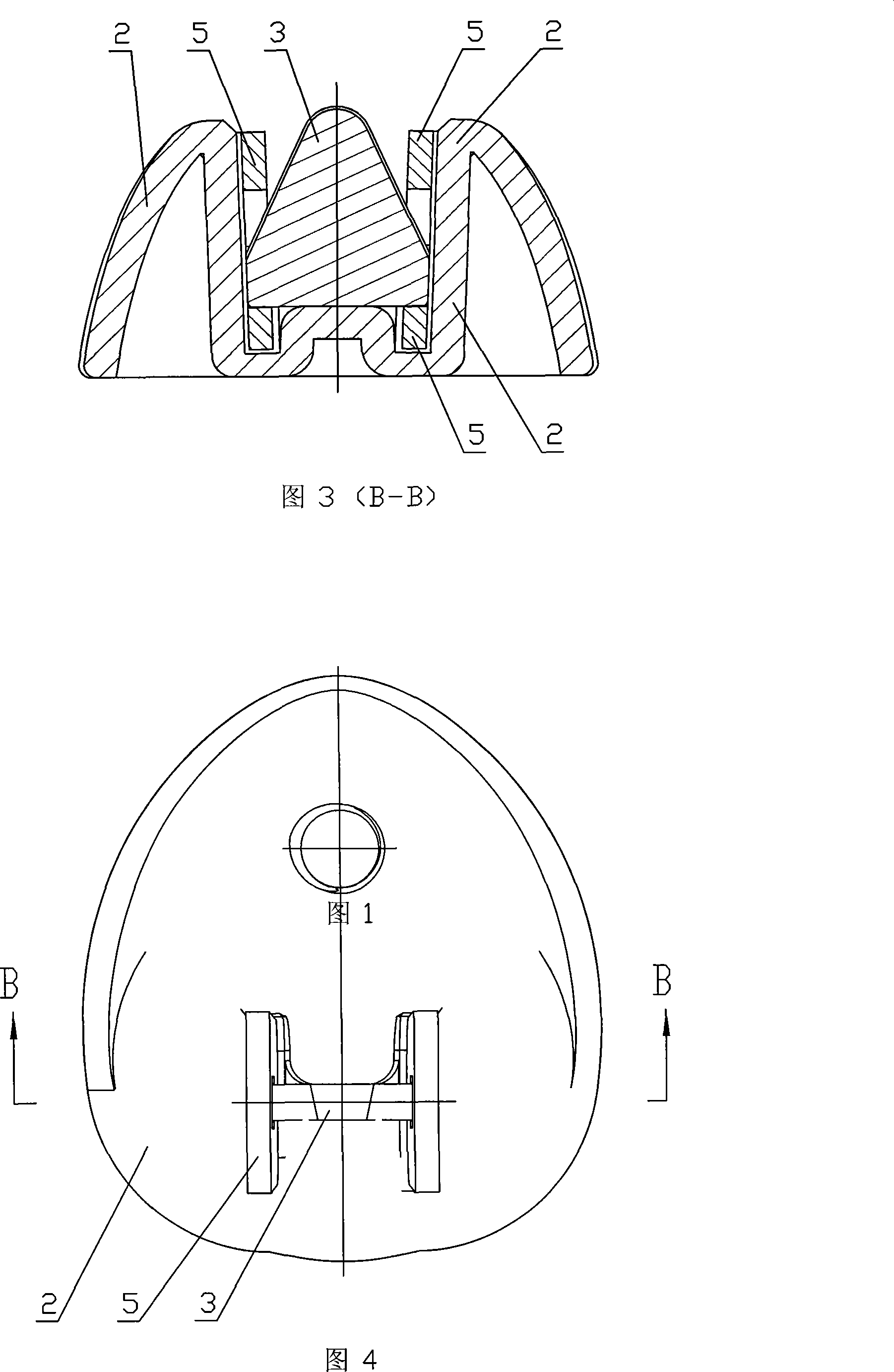

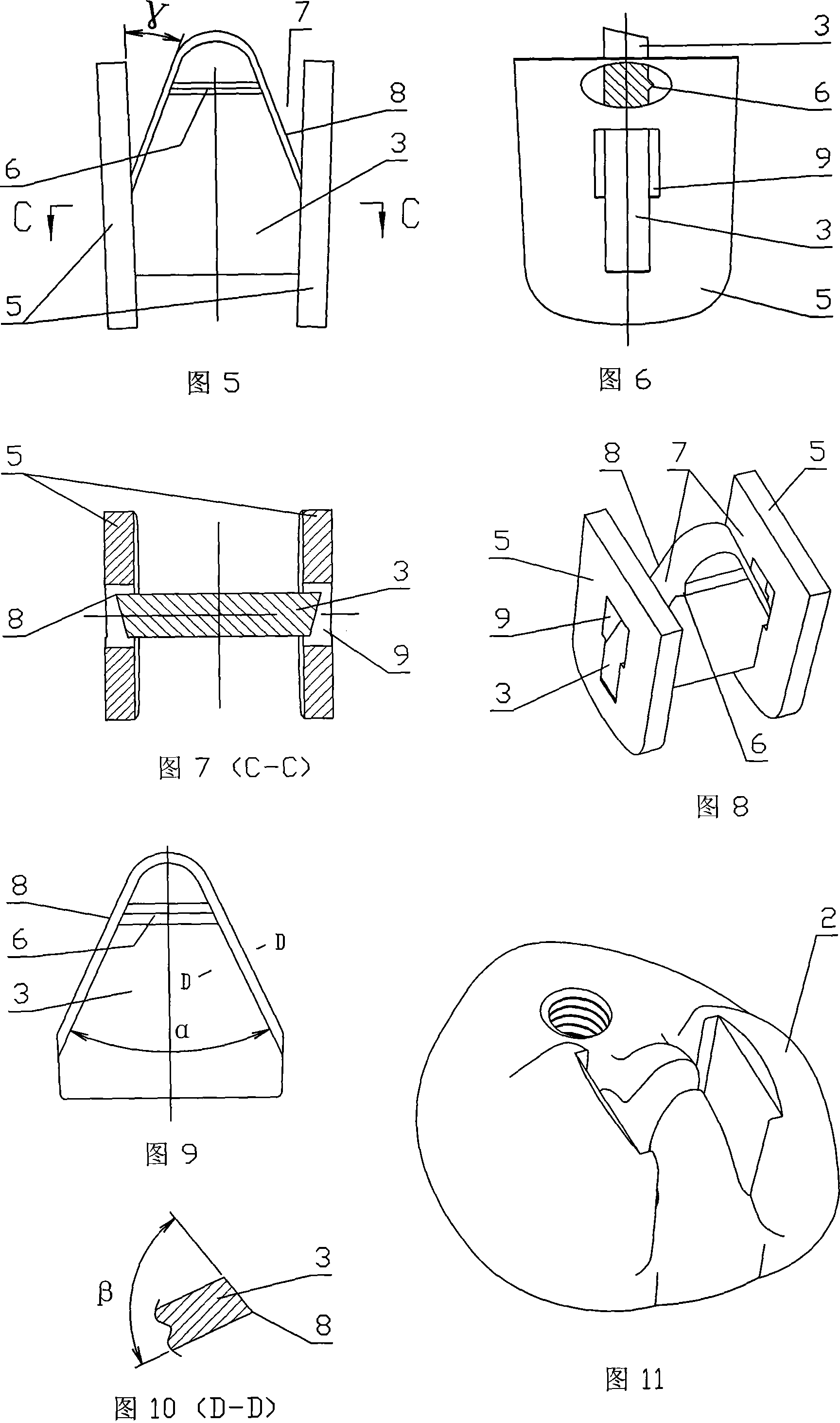

[0022] An example of an embodiment is shown in Figure 1-11: a suction cup sharpener, its bolt 4 is pre-embedded in a soft plastic suction cup 1 and is tightly connected with it as a whole, the screw hole of the support 2 is screwed with the bolt 4, Fasten the support 2 on the suction cup 1. Two rectangular linings 5 with rounded corners are placed in the groove of the support 2 in an inverted splayed shape. The center of the lining 5 is provided with a rectangular hole 9, and the two sides of the lower part of the single carbide grinding blade 3 are positioned and inserted in In the oblong holes 9 of the left and right linings 5, the whole is packed into the groove of the support 2. Carbide grinding blade 3 is an isosceles triangular thin-shaped frustum with rounded corners, and the large isosceles triangular surface of the truncated cone is a smooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com