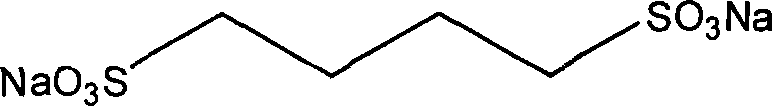

Process for producing 1,4-sodium butanedisulfonic acid

A technology of sodium butylsulfonate and sodium sulfite, applied in 1 field, can solve the problems of long reaction time, low yield, cumbersome post-treatment, etc., and achieve the effects of simple operation, high yield and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

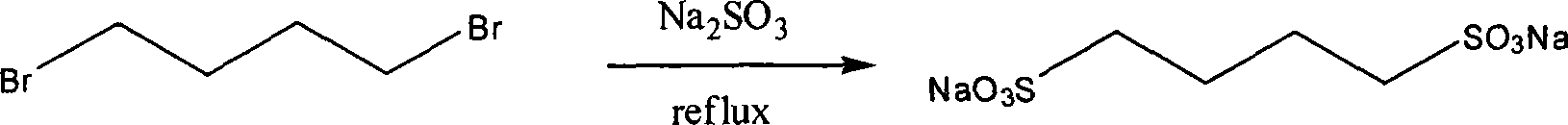

[0020] Embodiment 1: take 1,4-dibromobutane as raw material preparation 1,4-sodium butanedisulfonate

[0021] Add 7.56g (60mmol) of sodium sulfite, 3.6mL (30mmol) of 1,4-dibromobutane and 60ml of water into a 100ml single-necked bottle, heat and reflux in an oil bath (temperature 110-120°C) and react for about 10 hours. About 50ml of water in the reaction system was distilled off under reduced pressure, cooled and crystallized at 4°C, and the obtained white crystals were recrystallized twice with water and dried under vacuum at 60°C to obtain sodium 1,4-butanedisulfonate. ESI-MS: 261.94; 1 H NMR (DMSO-d 6 ) δ ppm: 2.38 (t, J=7.11, 4H), 1.59 (m, 4H). Yield: 95%.

Embodiment 2

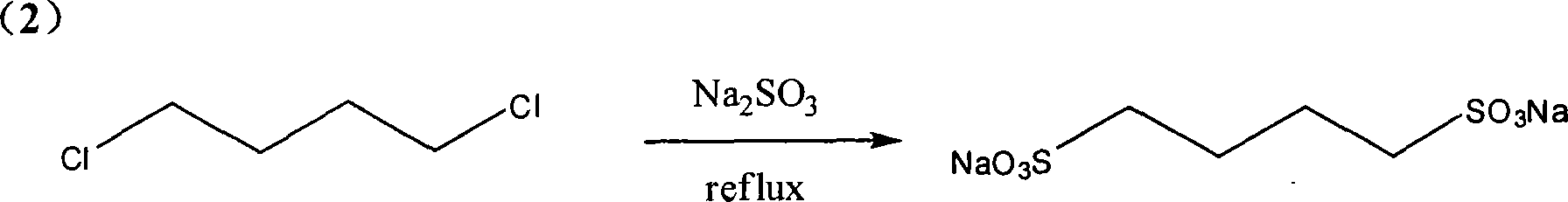

[0022] Embodiment 2: take 1,4-dichlorobutane as raw material preparation 1,4-sodium butanedisulfonate

[0023] Add 7.56g (60mmol) of sodium sulfite, 3.3mL (30mmol) of 1,4-dichlorobutane and 60ml of water into a 100ml single-necked bottle, heat and stir under reflux in an oil bath (temperature 110-120°C), and react for about 20 hours. About 50ml of water in the reaction system was distilled off under reduced pressure, cooled and crystallized at 4°C, and the obtained white crystals were recrystallized twice with water and dried under vacuum at 60°C to obtain sodium 1,4-butanedisulfonate. ESI-MS: 261.98; 1 H NMR (DMSO-d 6 ) δ ppm: 2.39 (t, J = 7.11, 4H), 1.58 (m, 4H). Yield: 83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com