Portrait multi-point continuously dragging construction method for trussed steel beam

A construction method and technology of steel truss girder, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of unsuitable use in strong wind areas, difficult temporary piers, and great environmental impact of temporary piers, so as to shorten the construction period, Safe production is beneficial and the effect of reducing high-altitude work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

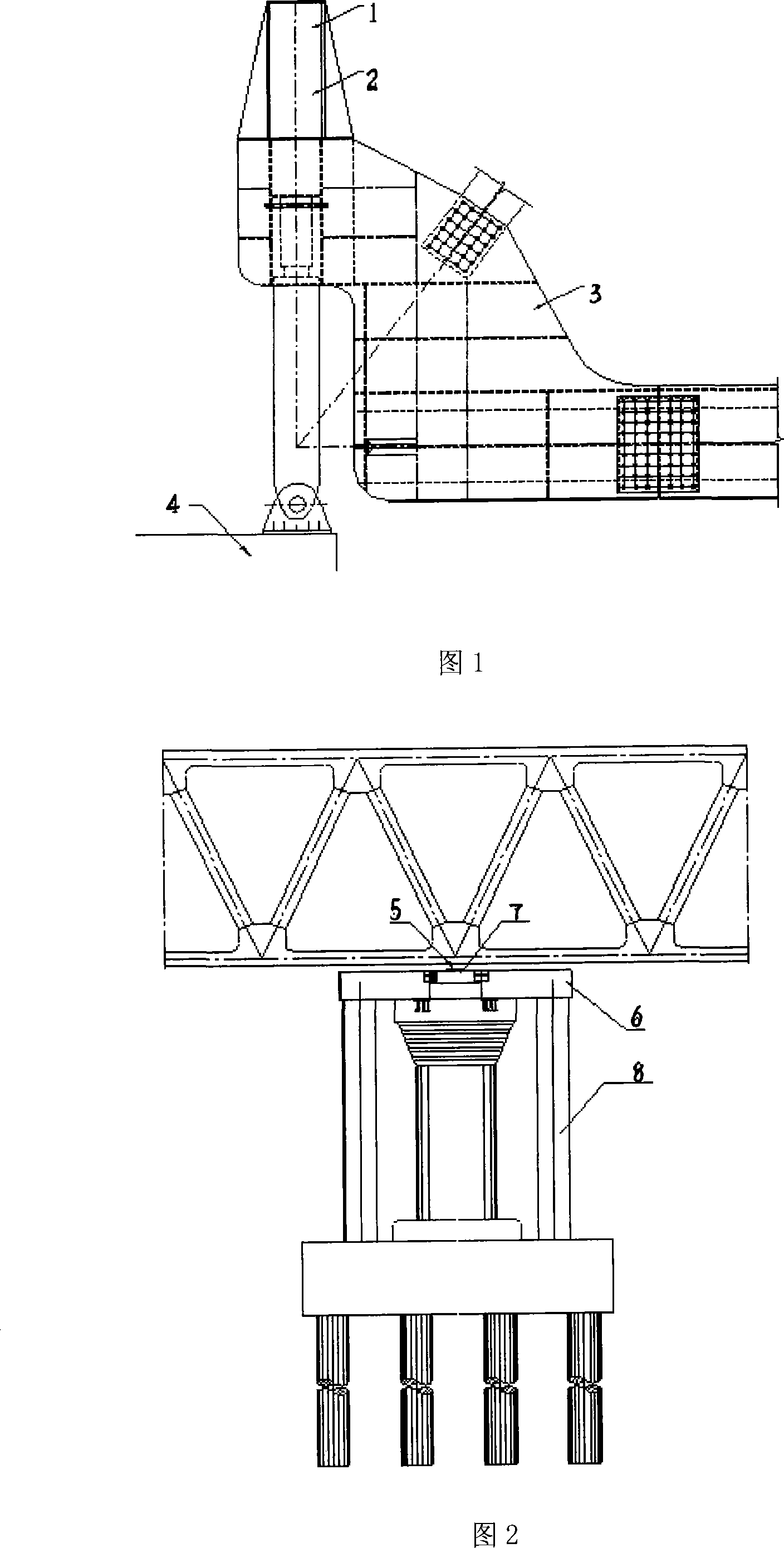

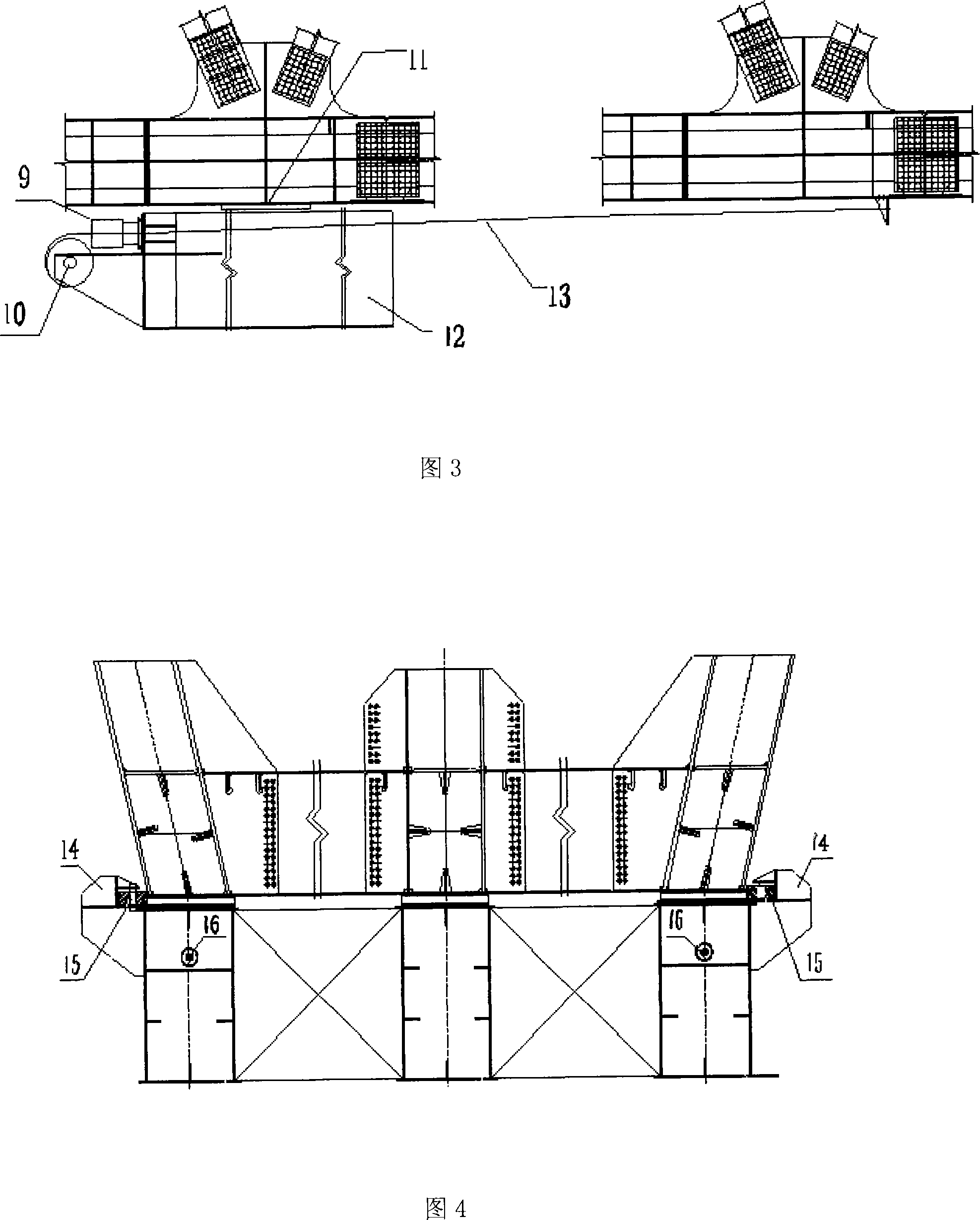

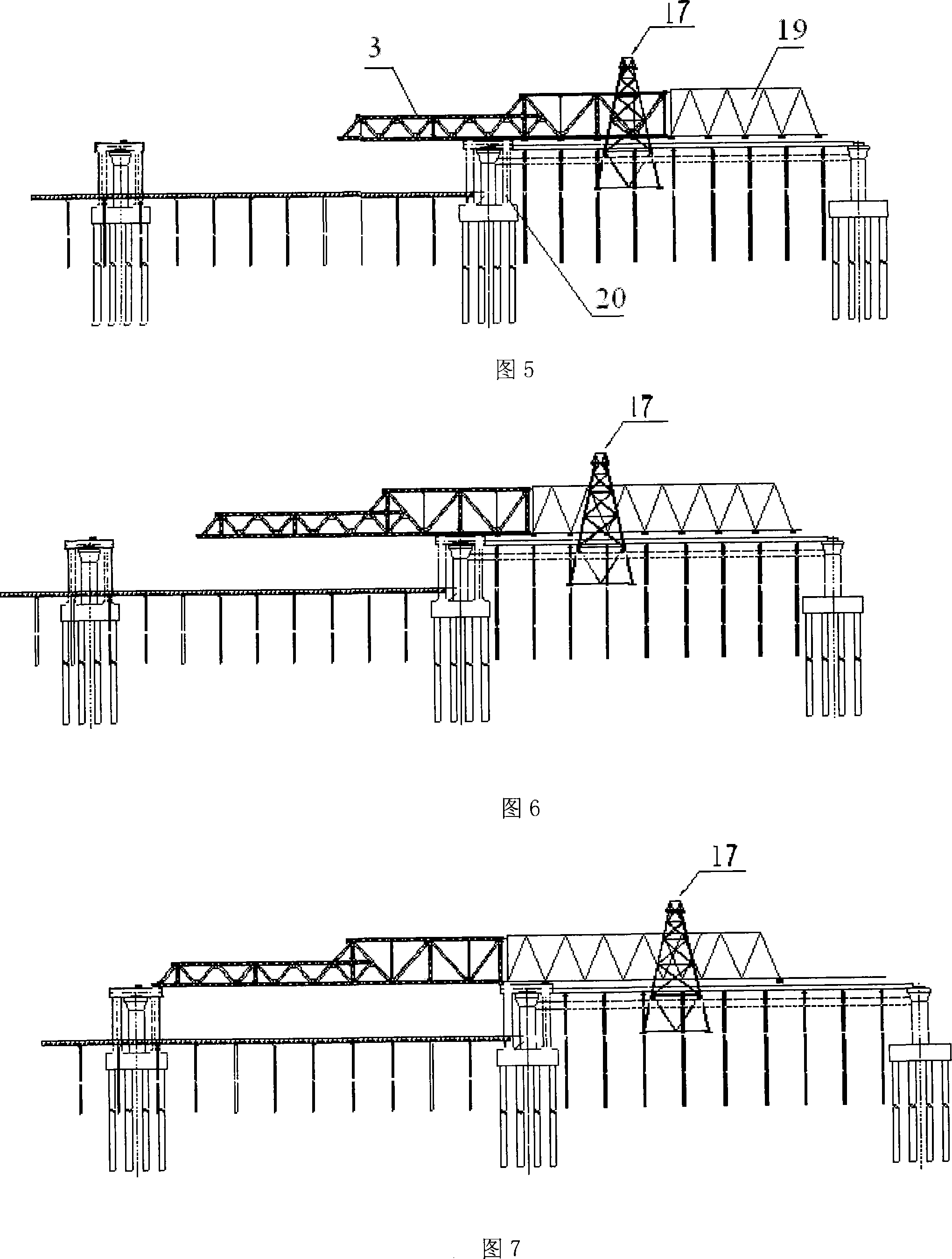

[0049] 1. Set up the construction platform support on the 7~8# pier, install the 108m guide beam 108m on the support, then drag the guide beam to the 0# pier direction and move forward for 48m, and assemble the 4 steel truss girders. See Figure 5

[0050] 2. Then drag 36m towards the direction of pier 0#, and continue to assemble 3 sections of the steel truss girder. See Figure 6

[0051] 3. Drag 30m in the direction of pier 0#, and the leading beam reaches the bracket next to pier 6#. See Figure 7

[0052] 4. Continue to drag 54m in the direction of pier 0#, and 7 internode positions are vacated on the scattered support. See Figure 8

[0053] 5. Assemble 7 internodes of steel truss beams on the steel beam assembly platform support.

[0054] 6. Drag 84m as a whole, and then assemble 7 steel truss girders on the steel girder assembly platform support. See Figure 9

[0055] 7. Repeat the above steps, and drag the steel truss beam to the 0# pier. (The guide beam can be di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com