Joint lever for adsorption tower

A technology of connecting rods and adsorption towers, applied in the field of pressure swing adsorption gas devices, to achieve the effect of low wall-attachment effect and high gas purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

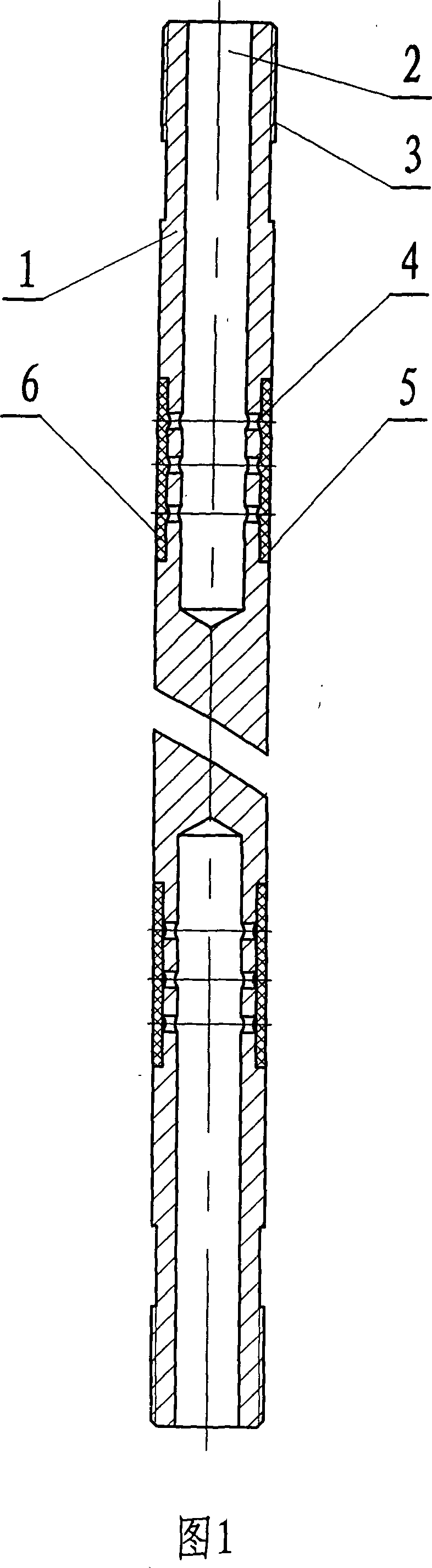

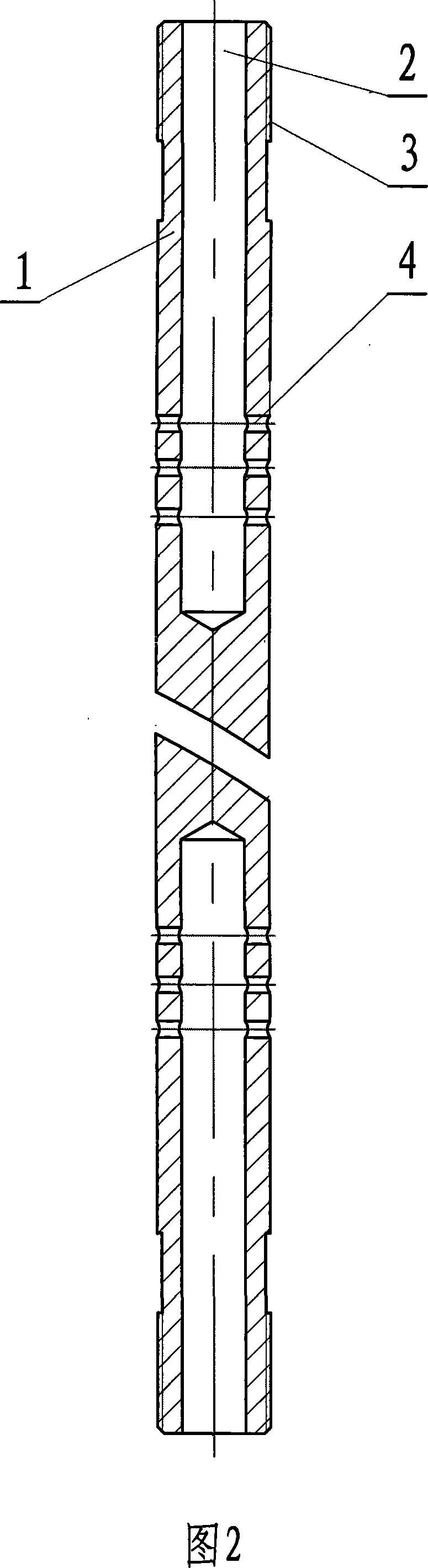

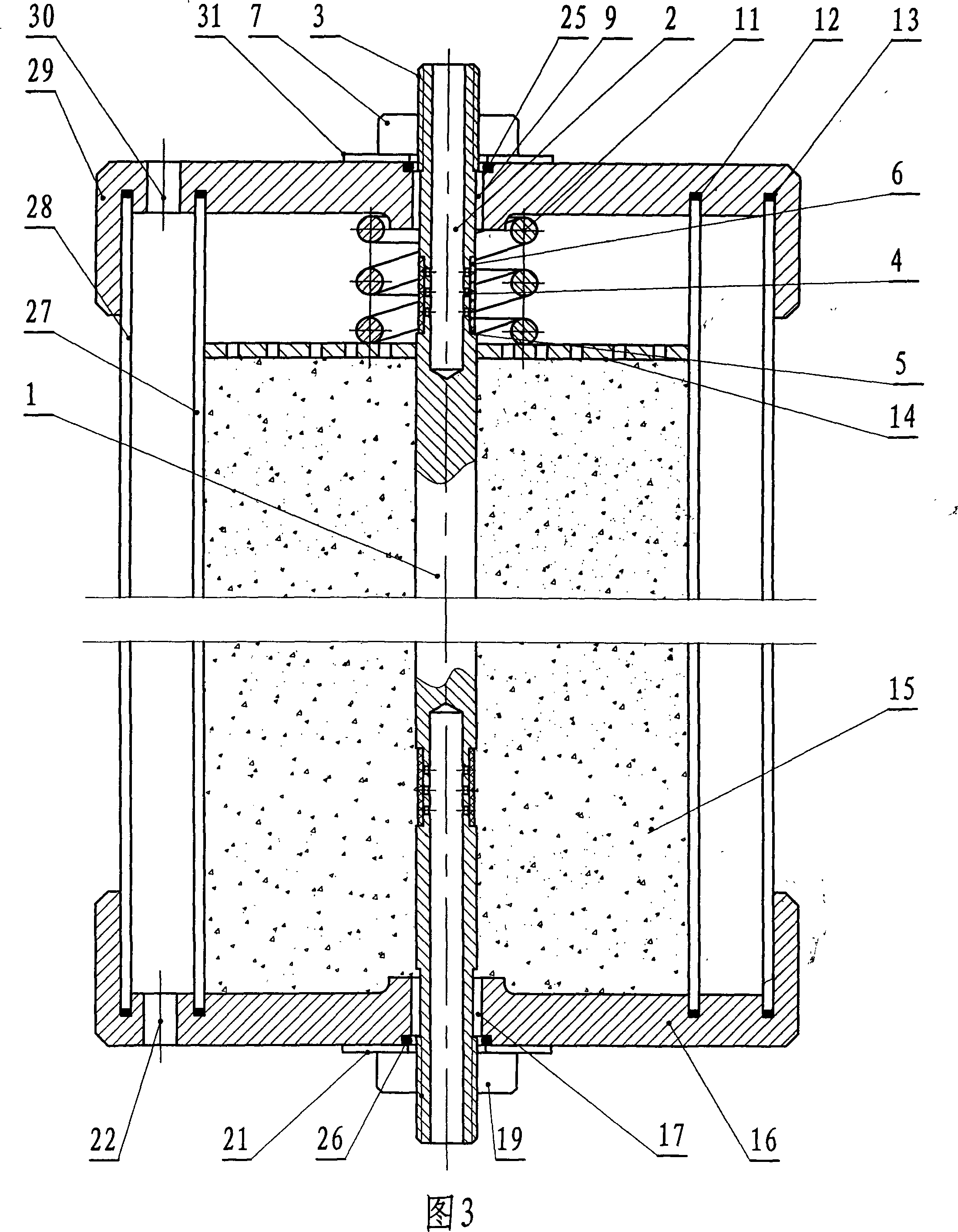

[0012] Below in conjunction with accompanying drawing, the present invention will be further described

[0013] The two ends of a connecting rod 1 for an adsorption tower shown in Fig. 1 are each provided with an axial blind hole 2, and a radial hole 4 is connected between the axial blind hole and the outer circumferential surface of the connecting rod, and the radial hole is opposite to the connecting rod. Axisymmetric distribution, the diameter of the radial hole is greater than or equal to 0.2 mm, the diameter of a section of the outer circle of the connecting rod with the radial hole is 5 less than the diameter of other parts of the connecting rod, and the outer circumferential surface of the radial hole is wrapped with a filter net6.

[0014] Threads 3 are provided at the outer circles of both ends of the connecting rod, the material of the connecting rod is stainless steel, the material of the filter net is also stainless steel, and the number of the radial holes is 3 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com