Wall-attachment fluidic sprinkler

A wall-attached jet and nozzle technology, applied in the direction of spraying devices, spraying devices, spraying devices with movable outlets, etc., can solve the problems of complex reverse mechanism, gas-water separator can not work normally, fan-shaped spraying function can not be completed, etc. Achieve stable and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

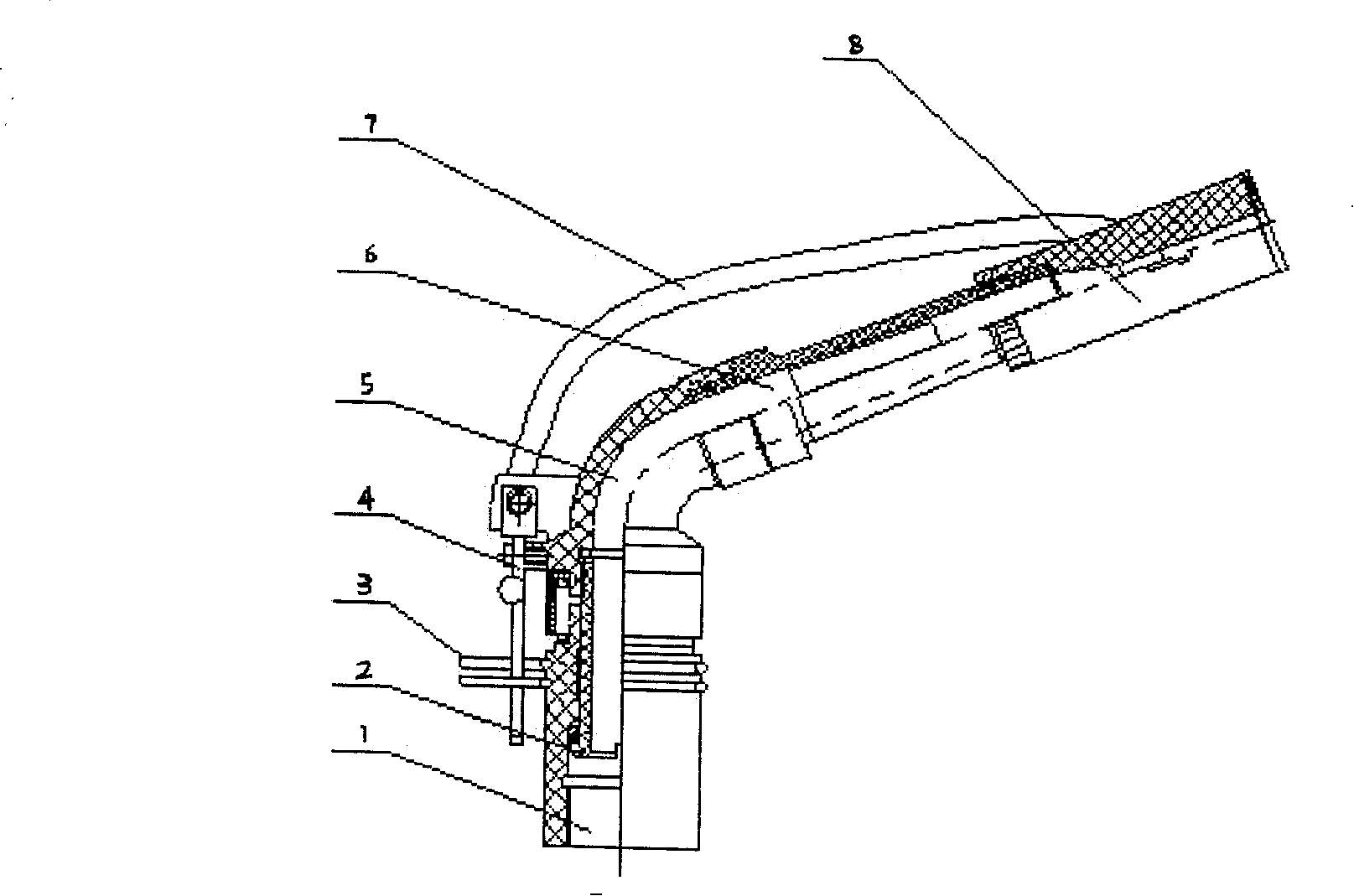

[0018] Example 1: The signal water nozzle is set in the working area of the component cavity. The working process of water intake is as follows:

[0019] Direct state: such as Figure 5 As shown, the water flow is sprayed from the hole D into the action area, from Figure 4 It can be seen from the A-direction view that the main jet is ejected from the central hole, and the left and right ends of the main jet are separated from each other, and the air at both ends cannot circulate. The reverse air supply nozzle (9) on the left side of the water jet element body is open, so as to supply air to the left cavity, and the gap C between the outlet on the right side of the element and the water beam is filled with air, so the pressure on the left and right sides is basically equal , the main jet is in a direct state, and the nozzle is stationary. At the same time, the signal water nozzle (10) has obtained signal water on the left edge of the water beam, and the signal water obtain...

Embodiment 2

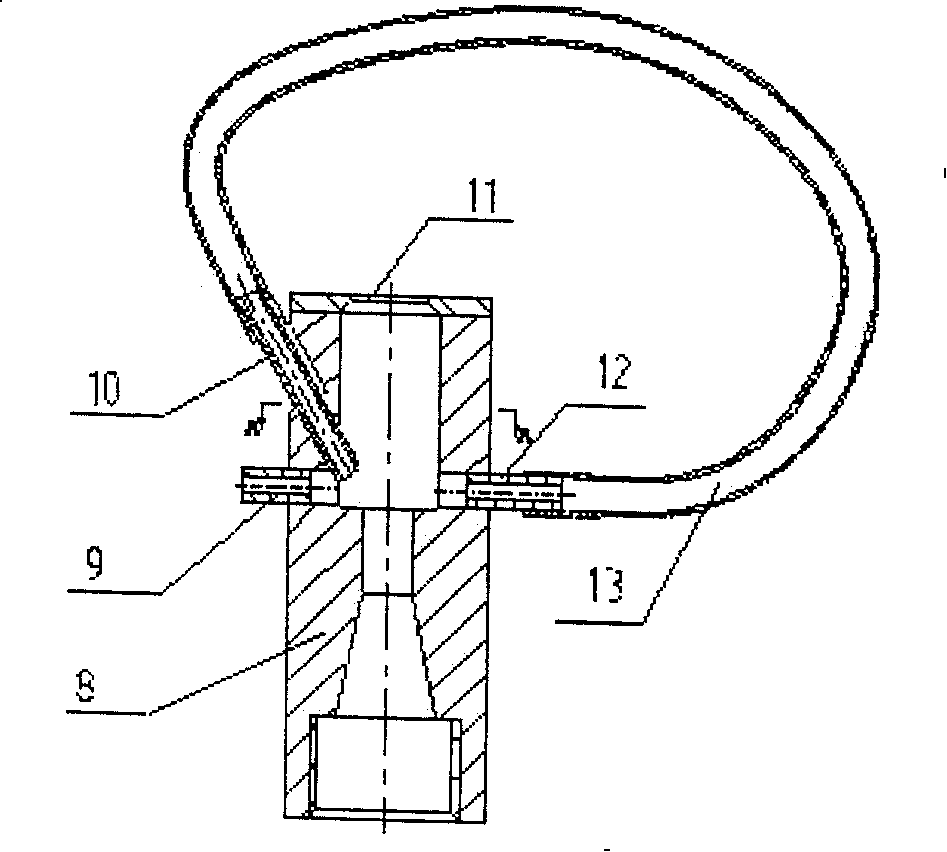

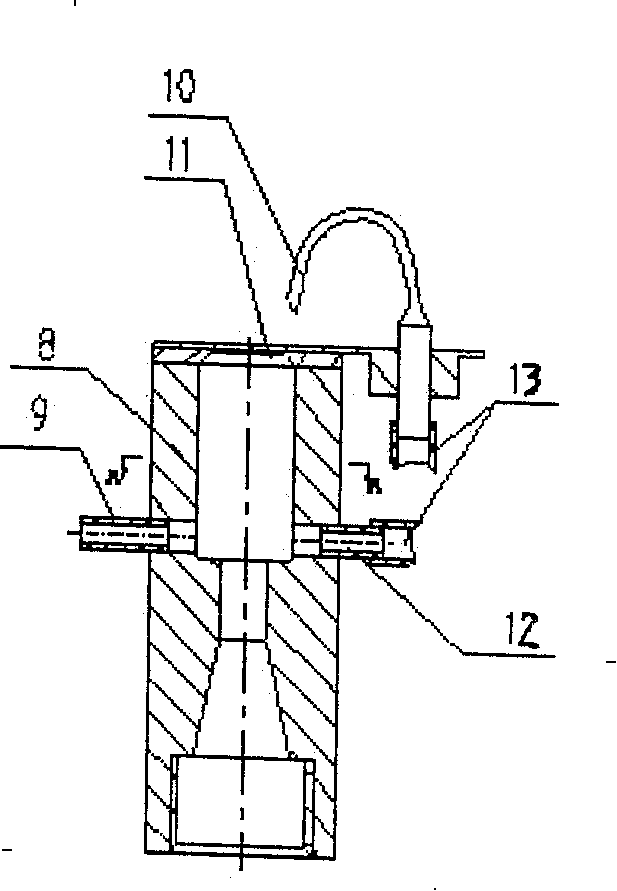

[0022] Example 2: The signal water nozzle is set outside the cover plate, and the water intake process is as follows:

[0023] The water flow is injected into the action area from the hole D, and the left and right ends of the action area form a low-pressure vortex area. The left side of the nozzle is supplied with air by the reverse air nozzle (9) through the reverse plastic pipe (7), and the right side is supplied with air by the signal water connector (10). The pressure on both sides is equal, the water flow is direct, and the nozzle is still. The signal water is taken out from the signal water connector (10) and flows into the signal water inlet nozzle (12), so that no air is added to the right side, and a low-pressure vortex area is formed on the right side, and the pressure on the left side is higher than that on the right side. The chamfering of the outlet cover plate (11) produces a driving force on the shower head to make the shower head rotate step by step. At this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com