Method for building retaining wall by using waste-old tyre and triangle strips

A technology for waste tires and retaining walls, applied in excavation, construction, water conservancy projects, etc., can solve problems such as poor soil reinforcement effect, small friction coefficient between grid structure and soil, and complicated process, so as to solve the problems of easy falling off and Easy to deform, improve the overall reinforcement effect, strong and durable to adapt to the effect of the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

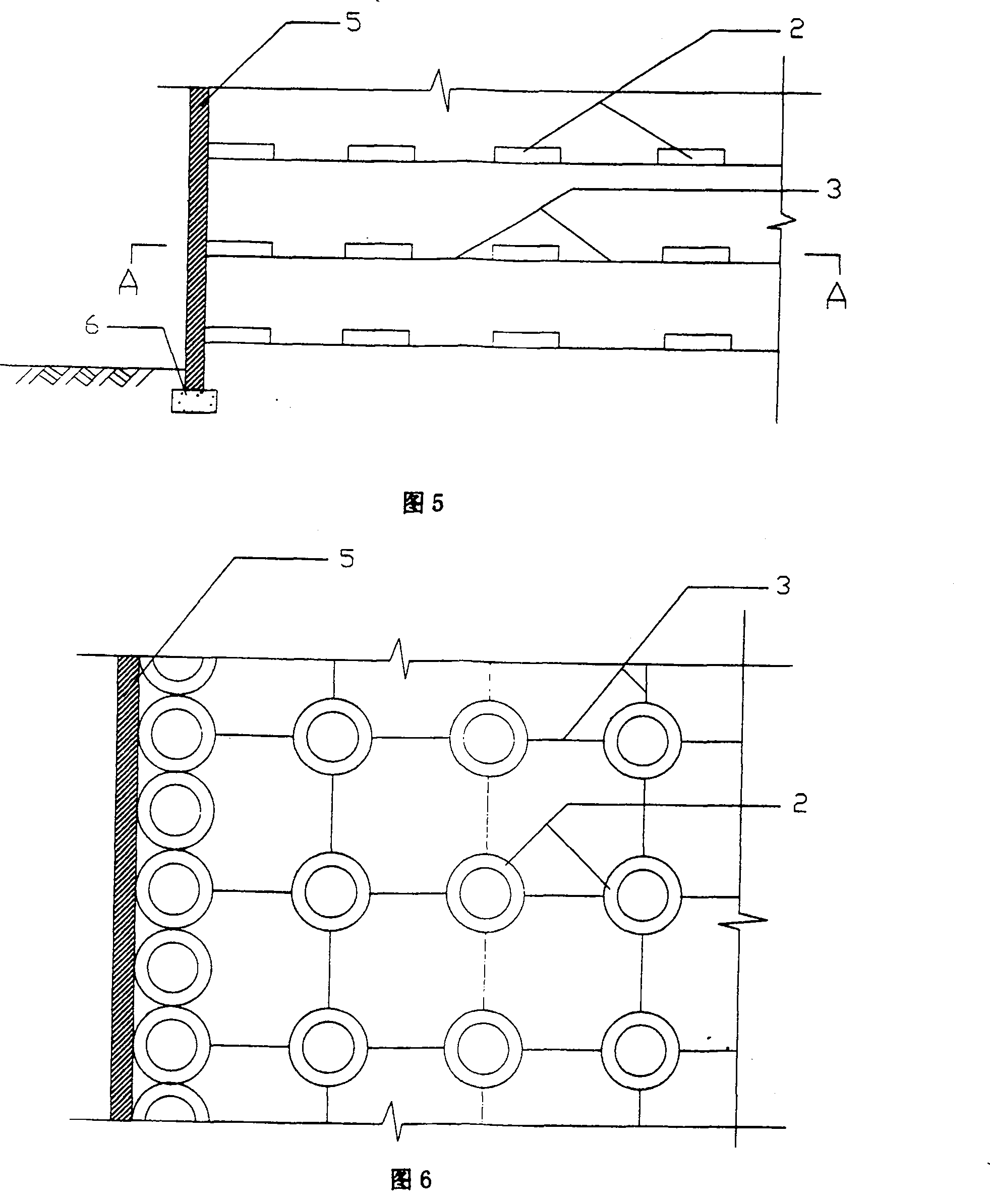

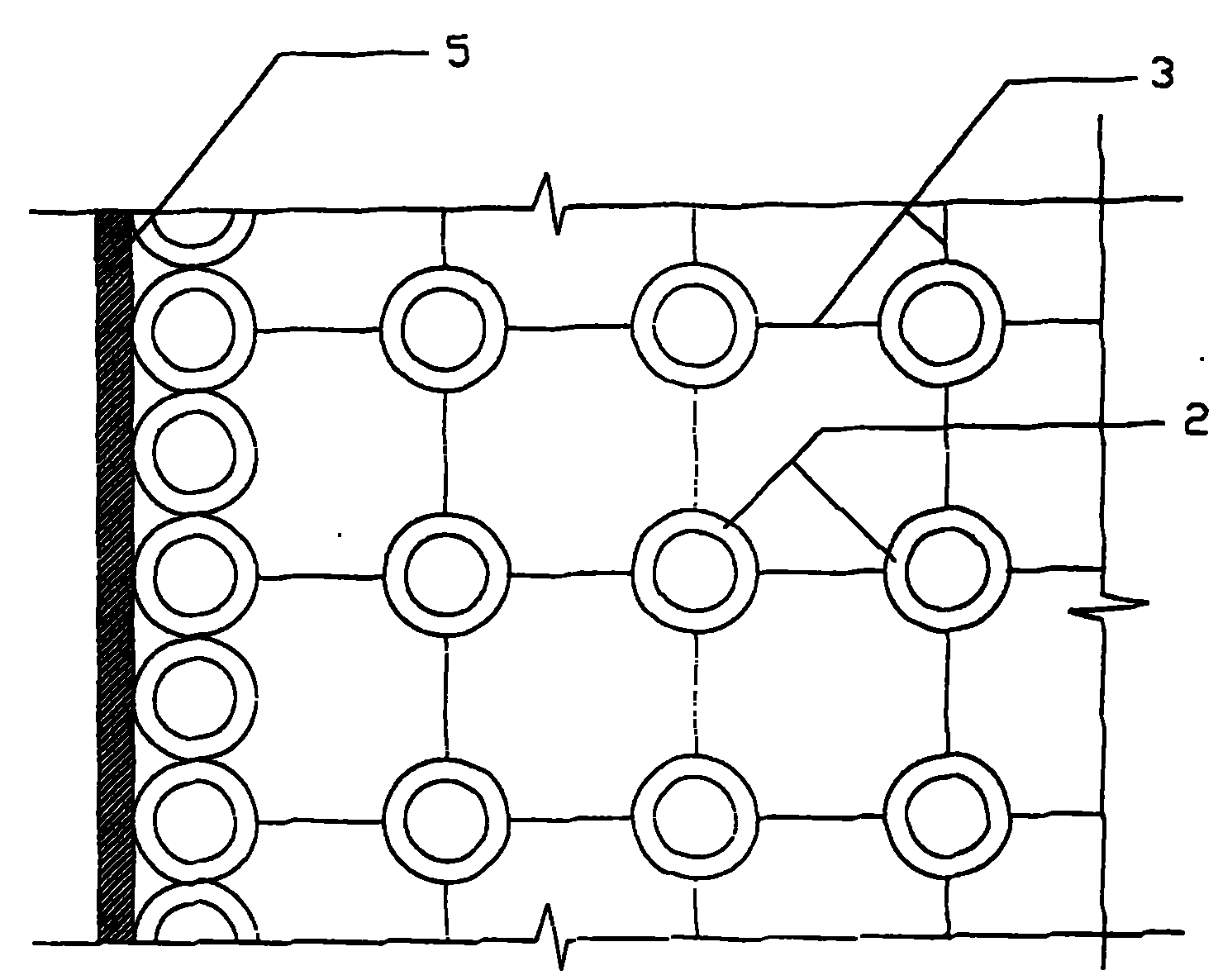

[0020] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

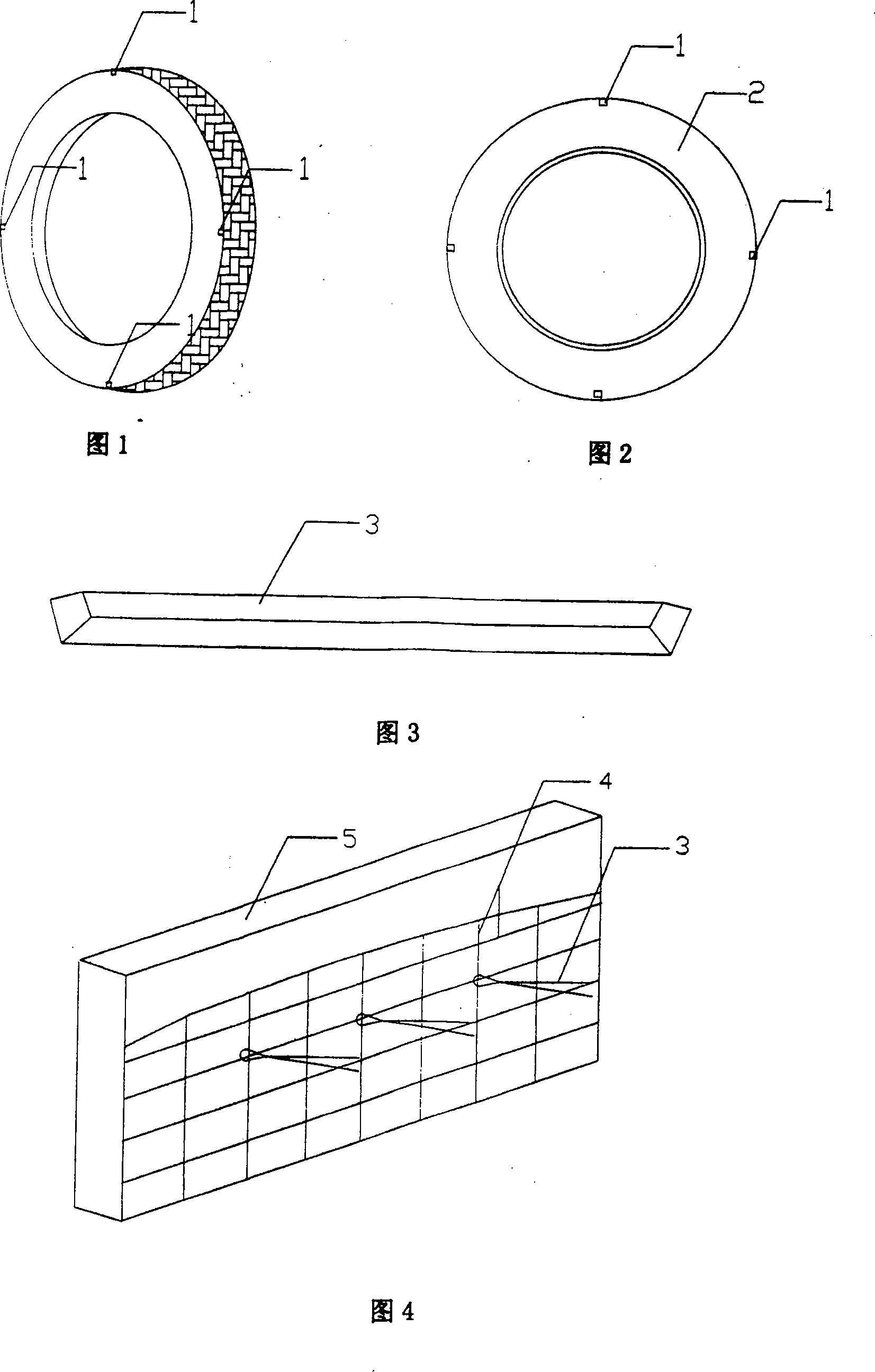

[0021] Such as figure 1 Shown is a side view of the entire tire. At the junction of the whole tire sidewall and the tread, the whole tire is equally divided into four points, and drilled at this place, the size of the reserved hole 1 will ensure that the triangle belt 3 passes through smoothly.

[0022] Such as figure 2 Shown, is the plan view of half tire 2. The whole tire is then cut longitudinally along the tread centerline into two equal halves 2 .

[0023] Such as image 3 Shown, is the side view of triangle belt 3. Cut and bind the discarded circular clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com