Shuttle type difference decompression valve

A pressure relief valve and shuttle technology, applied in the field of pressure relief valves, can solve the problems of ineffective take-off, large volume, ineffective return seat, etc., and achieve the effects of good symmetry and coaxiality, small overall volume and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

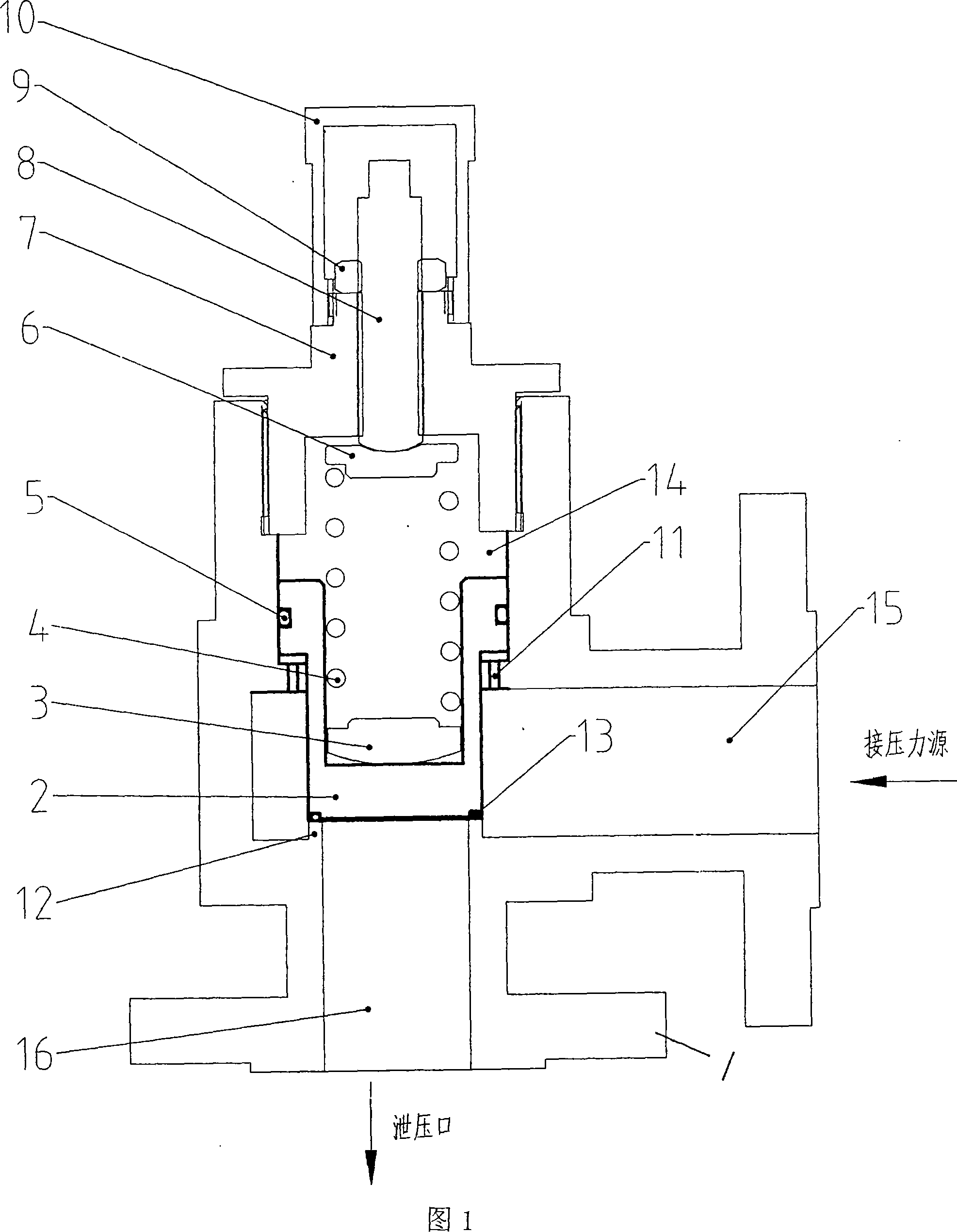

[0019] The valve body 1 is threadedly connected with the valve cover 7 . The spring adjusting rod 8 is threadedly connected with the inner hole of the valve cover 7 and has a locking nut 9 . The outer cover 10 is connected with the valve cover 7 and closes the upper end of the spring adjusting rod. The valve disc 2 is shuttle-shaped, and an arc-shaped spring seat 3 is connected with the lower end of the spring 4 on the inner cavity bottom plate, and the upper end of the spring 4 is connected with the lower end of the spring adjusting rod through the spring seat 6 . An annular space is formed between the step of the valve flap 2 and the stepped surface of the inner flange of the shuttle chamber 14 , and the space communicates with the pressure channel 15 of the valve body through the evenly distributed communication holes 11 on the inner flange of the shuttle chamber 14 . There is a valve seat 12 at the inner end of the discharge channel 16 of the valve body, and a sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com