Vacuum solar steam heat collection tube, steam heat collection plate, solar water-heating air conditioner device

A technology of solar steam and heat collecting tubes, which is applied in the fields of solar heat collecting elements, hot water devices and air conditioning devices, and can solve problems such as large resistance, short transportation distance and narrow application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

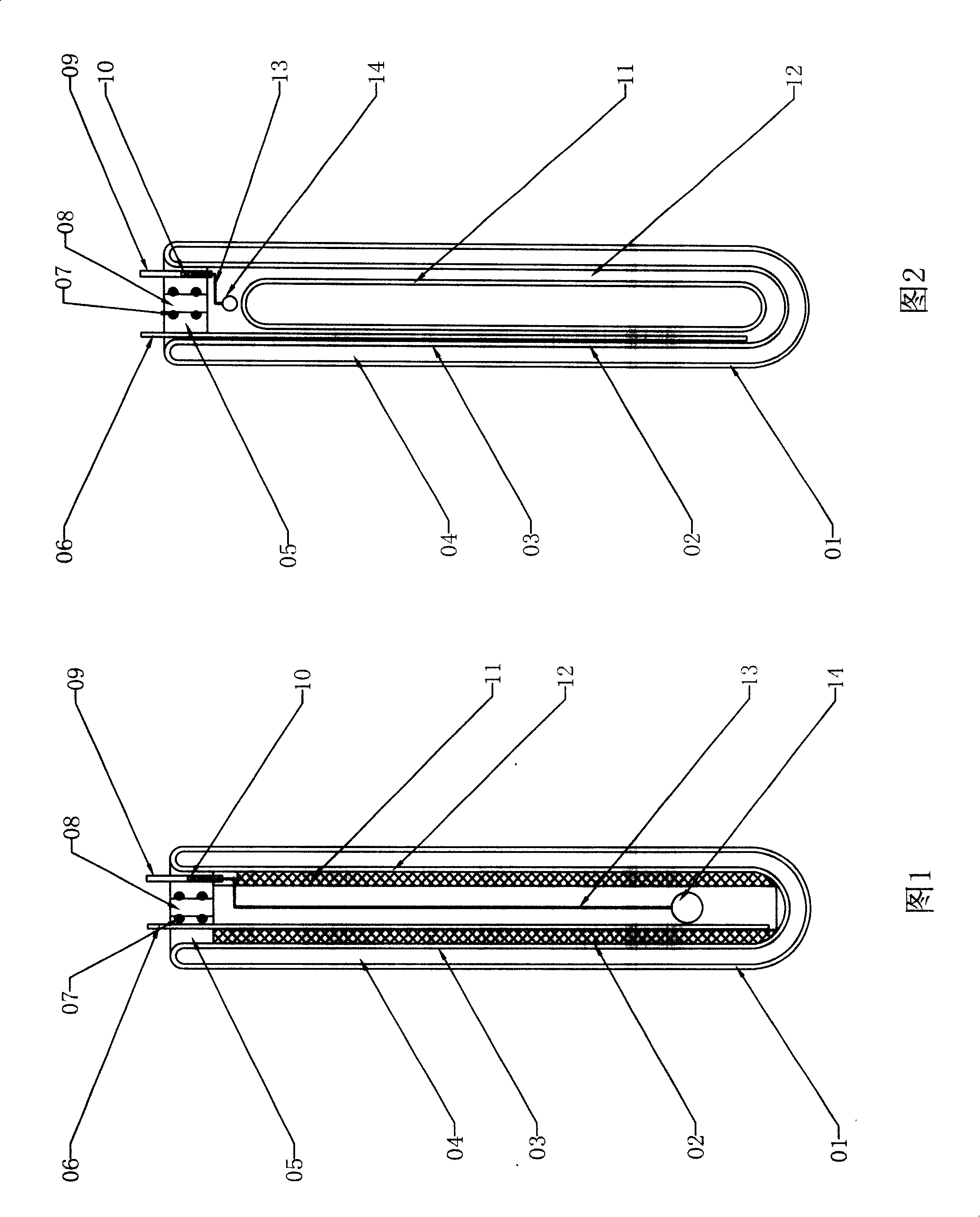

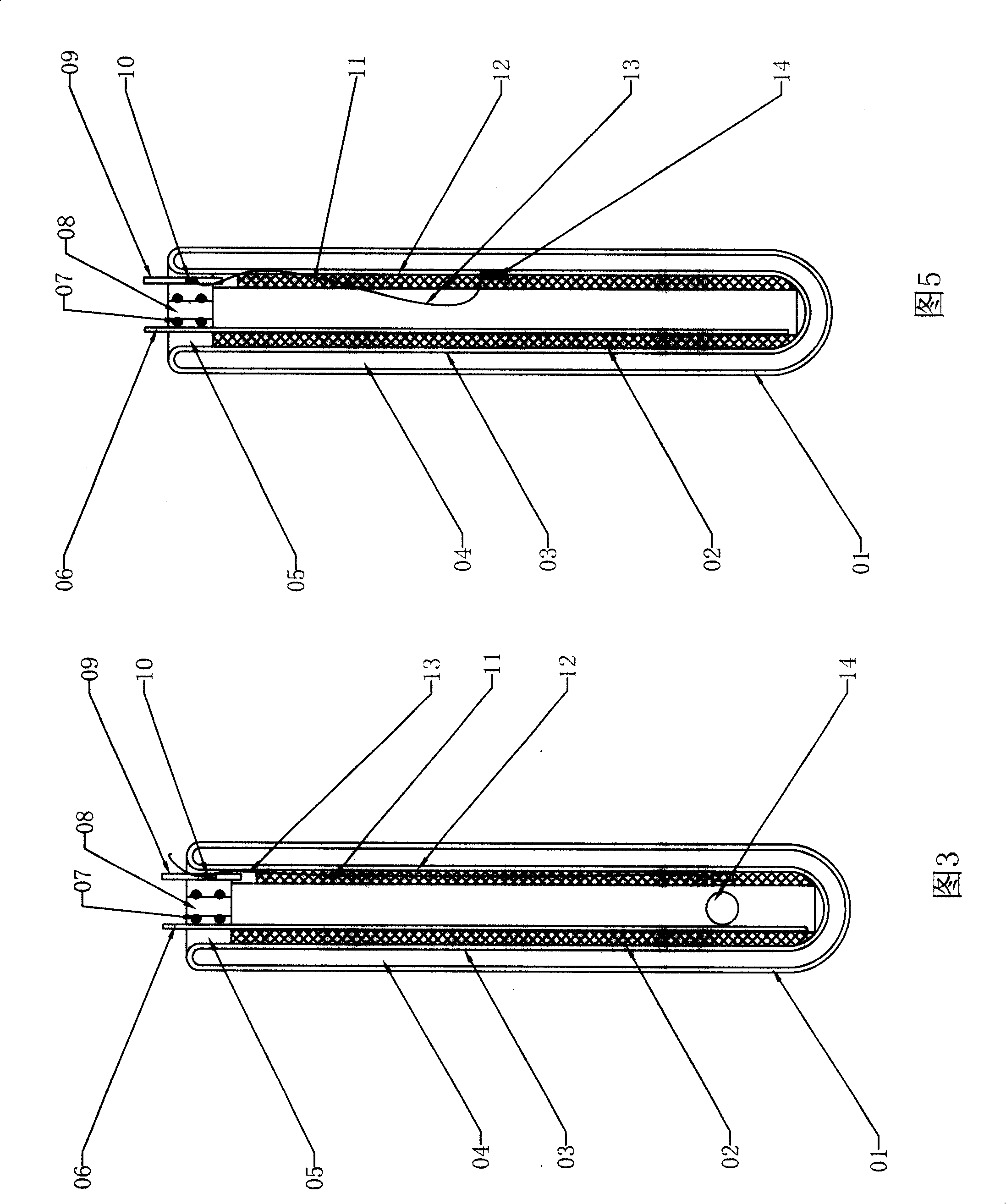

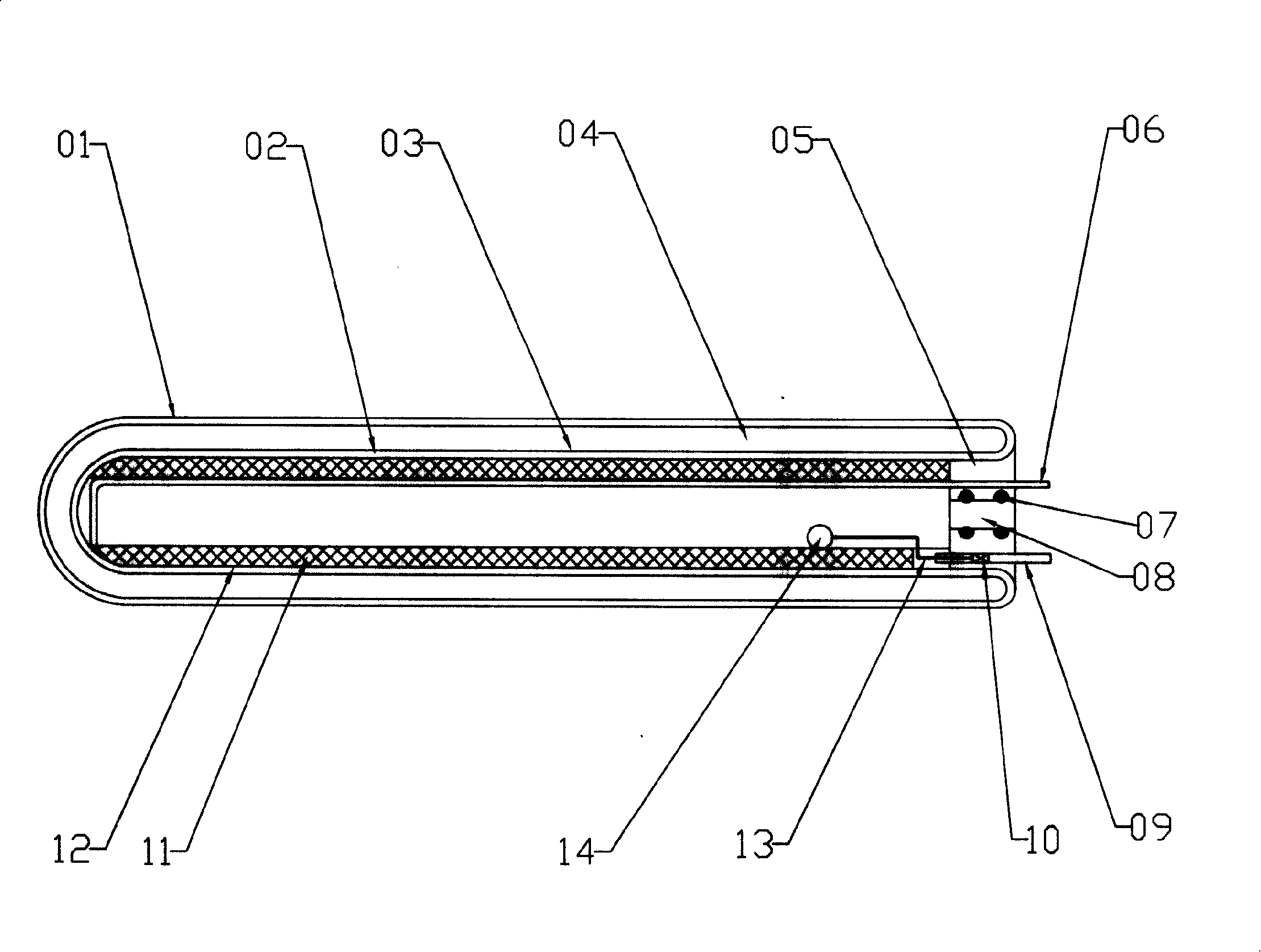

[0027] In the vacuum solar steam heat collection tube shown in Figure 1, one end of the transparent outer tube (01) is closed, and it is set on the outside of another inner tube (02) that is also closed at the same end, and its open ends are fused and sealed, between the two sleeves A vacuum interlayer (04) is formed between them, the outer surface of the inner tube (02) is coated with a selective solar absorbing coating (03), and a sealing end cover (05) is provided on the open end of the inner tube (02), and a sealing tape is provided on it. The exhaust port (08), liquid inlet pipe (09) and spare pipe (06) of (07), the liquid inlet pipe (09) is connected with the float regulating valve (10) and the liquid outlet is introduced into the core pipe (11) , the inner wall of the inner tube (02) is concentrically provided with a multi-gap capillary core tube (11), the core tube (11) is filled with liquid medium, and an annular liquid film (12) is formed on the wall of the inner tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com