Method for detecting lithium ion battery airtightness

A technology for air tightness testing and lithium-ion batteries, which can be used in fluid tightness testing, electrical components, secondary batteries, etc., and can solve problems such as batteries entering the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for detecting air tightness of a lithium ion battery, comprising the steps of:

[0023] Carry out air tightness test on 30 unsealed batteries with aluminum case 423450 at an air pressure of 0.093MPa, and record the corresponding air leakage rate of each battery;

[0024] b. Bake the battery at 65°C for 16 hours;

[0025] c. Inject the electrolyte into the battery;

[0026] d. Seal the battery injection hole;

[0027] e. Immerse the battery in water for 3 minutes;

[0028] f. Take out the battery and let it stand for 30 minutes;

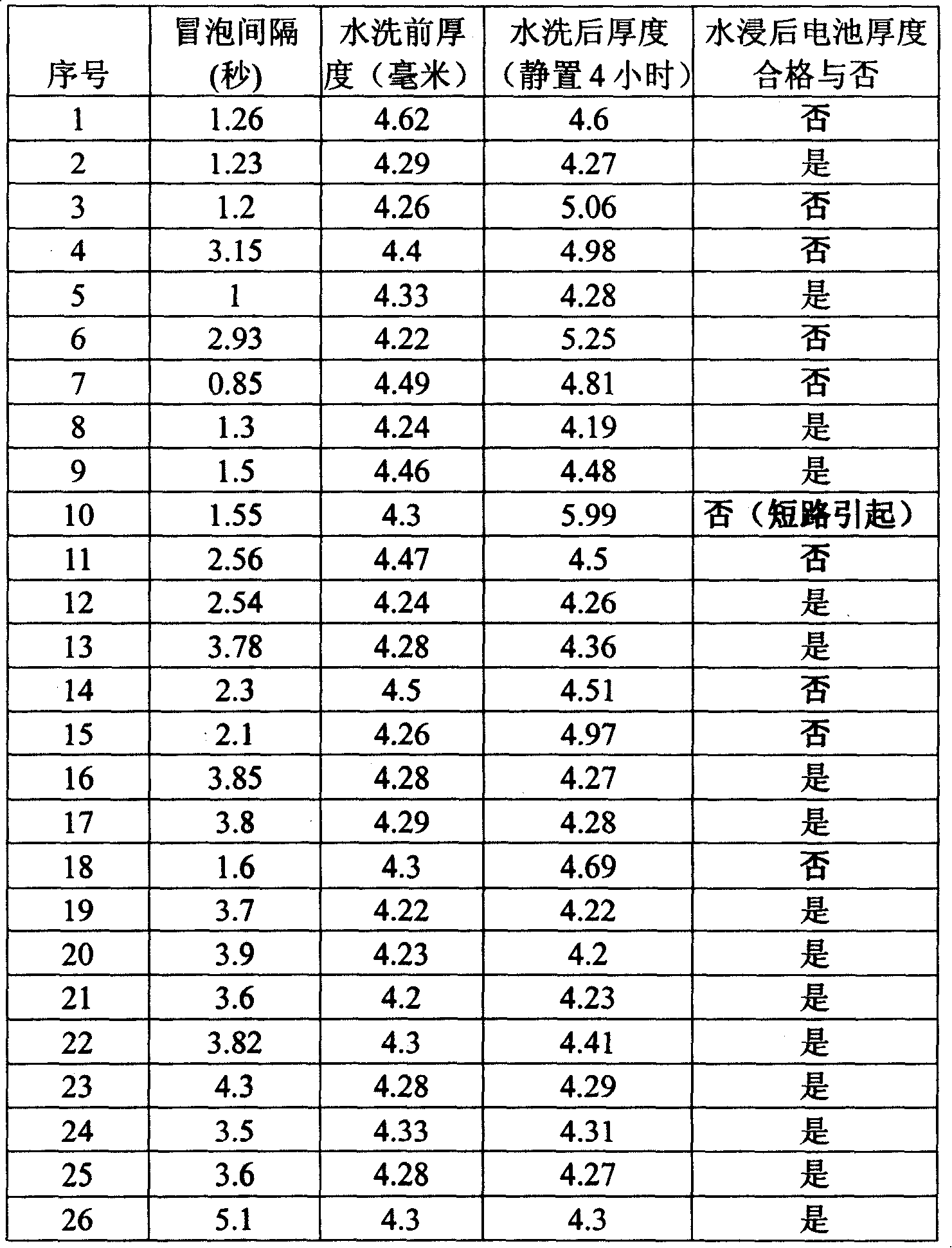

[0029] g. Measure the thickness of each battery, and judge whether its thickness variation range is qualified, see Table (1);

[0030] h. According to the battery whose thickness change is qualified, it is determined that the air leakage speed range corresponding to the air leakage rate during the air tightness test is not less than 3.5 seconds when the time difference between the bubbles is not less than 3.5 seconds.

[0031] i. ...

Embodiment 2

[0038] A method for detecting air tightness of a lithium ion battery, comprising the steps of:

[0039] a. Carry out air tightness test on 30 unsealed 423450 batteries with aluminum casing at an air pressure of 0.093MPa, and record the corresponding air leakage rate of each battery;

[0040] b. Bake the battery at 70°C for 10 hours;

[0041] c. Inject the electrolyte into the battery, then place the battery for aging and pre-charge

[0042] d. Seal the battery injection hole;

[0043] e. Immerse the battery in water for 10 minutes;

[0044] f. Take out the battery and let the battery stand for 4 hours;

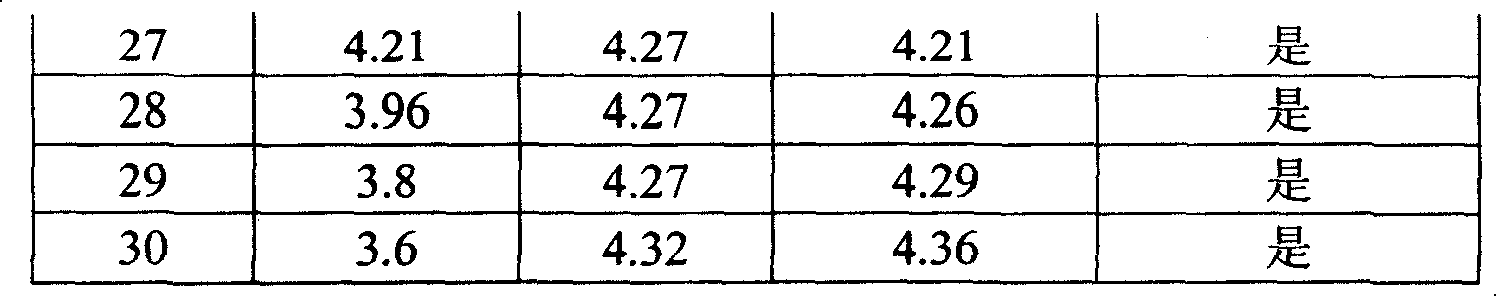

[0045] g. Measure the thickness of each battery, and judge whether its thickness variation range is qualified, see Table (2);

[0046] h. According to the battery whose thickness change is qualified, it is determined that the air leakage speed range corresponding to the air leakage rate during the air tightness test is not less than 3.5 seconds when the time difference bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com