Method of producing polymer field-flow fractionation chip

A production method and field flow separation technology, applied in the field of biological separation, can solve problems such as unfavorable batch production and low productivity, and achieve the effects of easy online monitoring, convenient selection, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

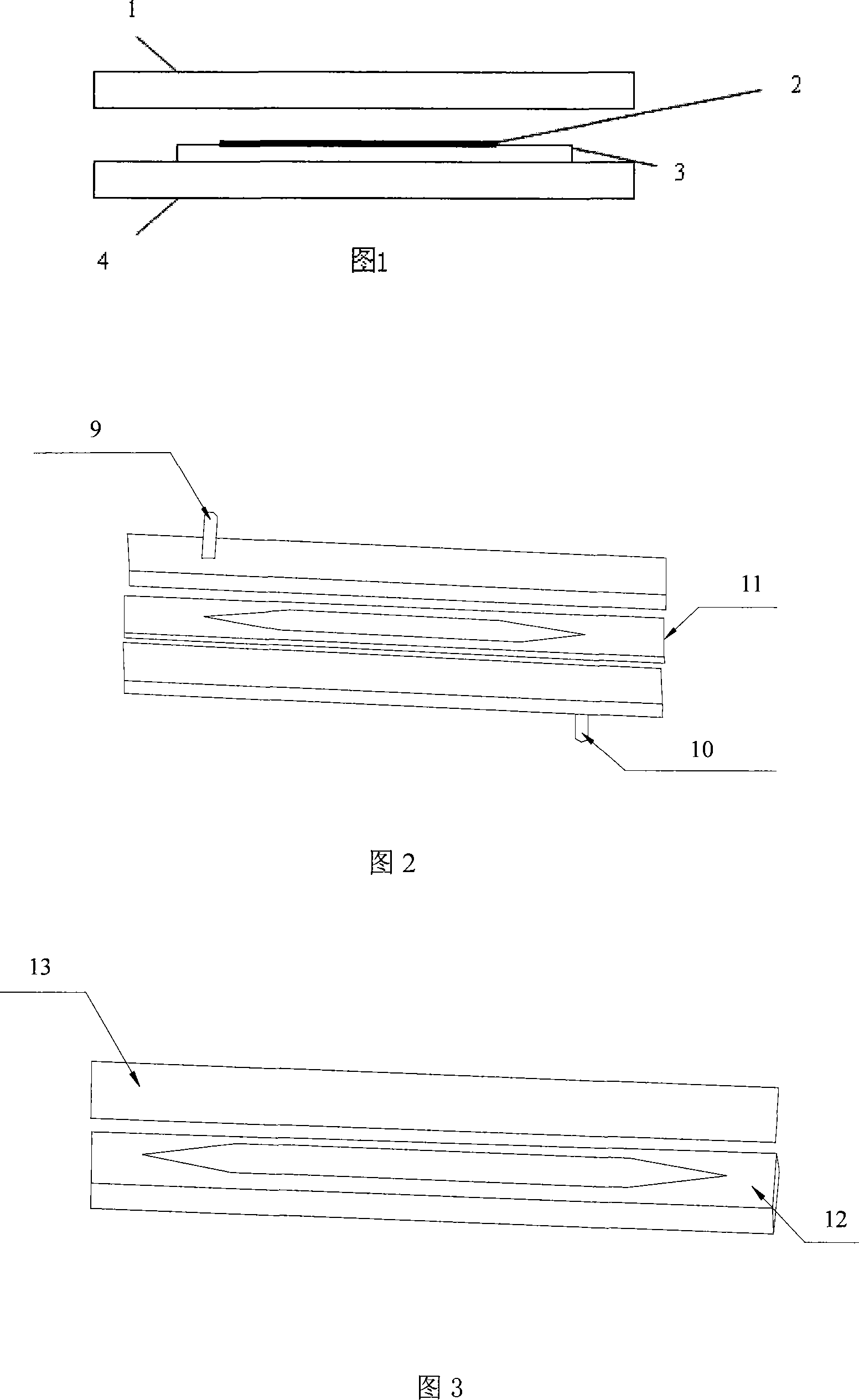

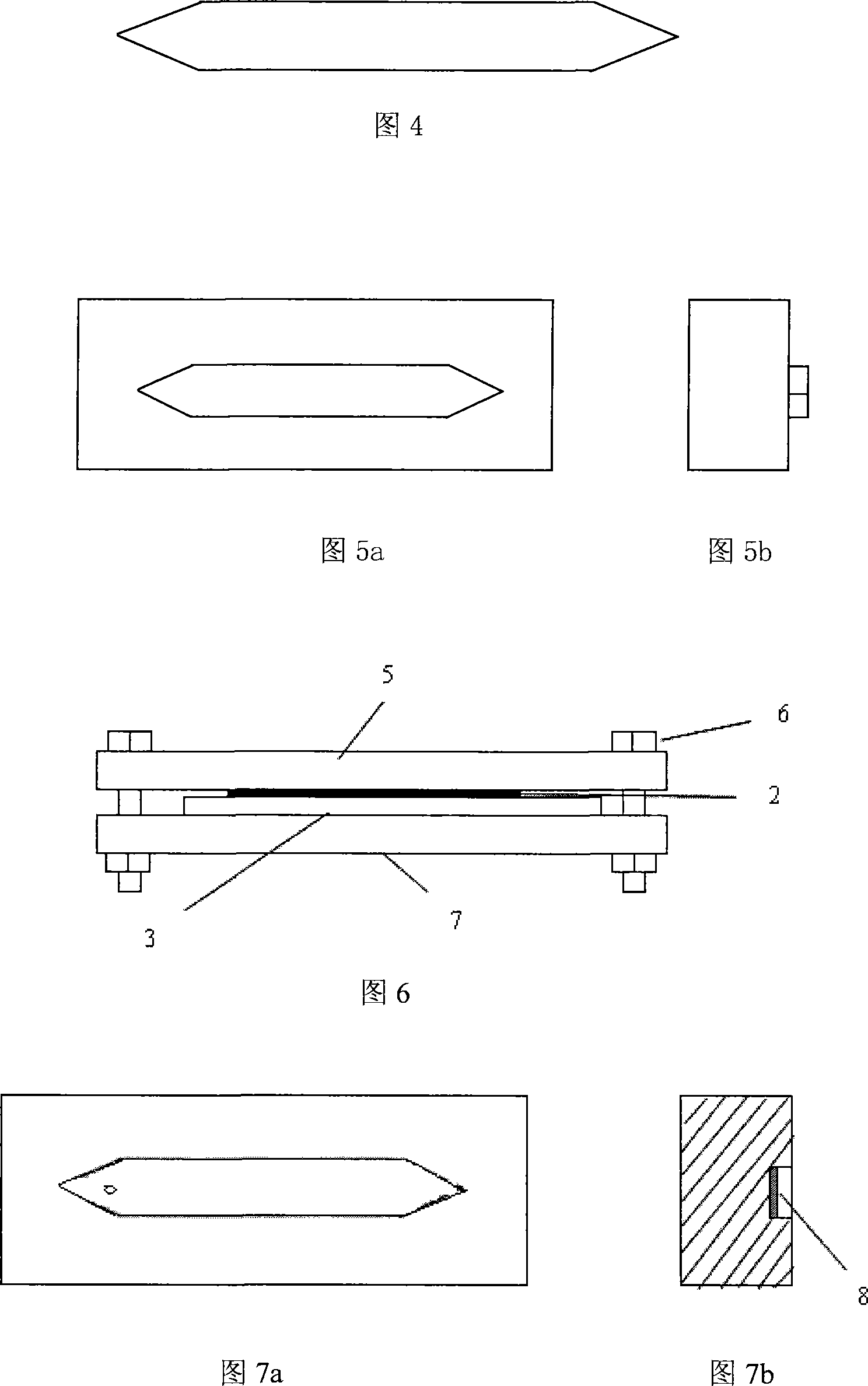

[0031] The specific content of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0032] In the method, a separation flow channel is manufactured by a hot molding process, and a separation flow channel system is formed by a thermal bonding process. The method comprises: making a hot-pressing template, hot-molding the separation flow channel of the chip, and thermal bonding of the separation flow channel system of the chip.

[0033] 1. Fabrication of hot pressing template

[0034] There are three kinds of manufacturing methods of the hot pressing formwork of the present invention:

[0035] The first method: take the metal plate that is the same as the depth of the separation channel or greater than the depth of the separation channel as the blank, and the surface of the blank plate is required to be flat enough, and no protrusions or depressions are allowed on the surface. If the rough material does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com