Wafer carrier vehicle

A technology of transport vehicles and wafers, which is applied in transportation and packaging, trolleys, motor vehicles, etc. It can solve the problems of chronic pain in the back and waist of workers, affect the physical and mental health of employees, and achieve the effect of avoiding human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

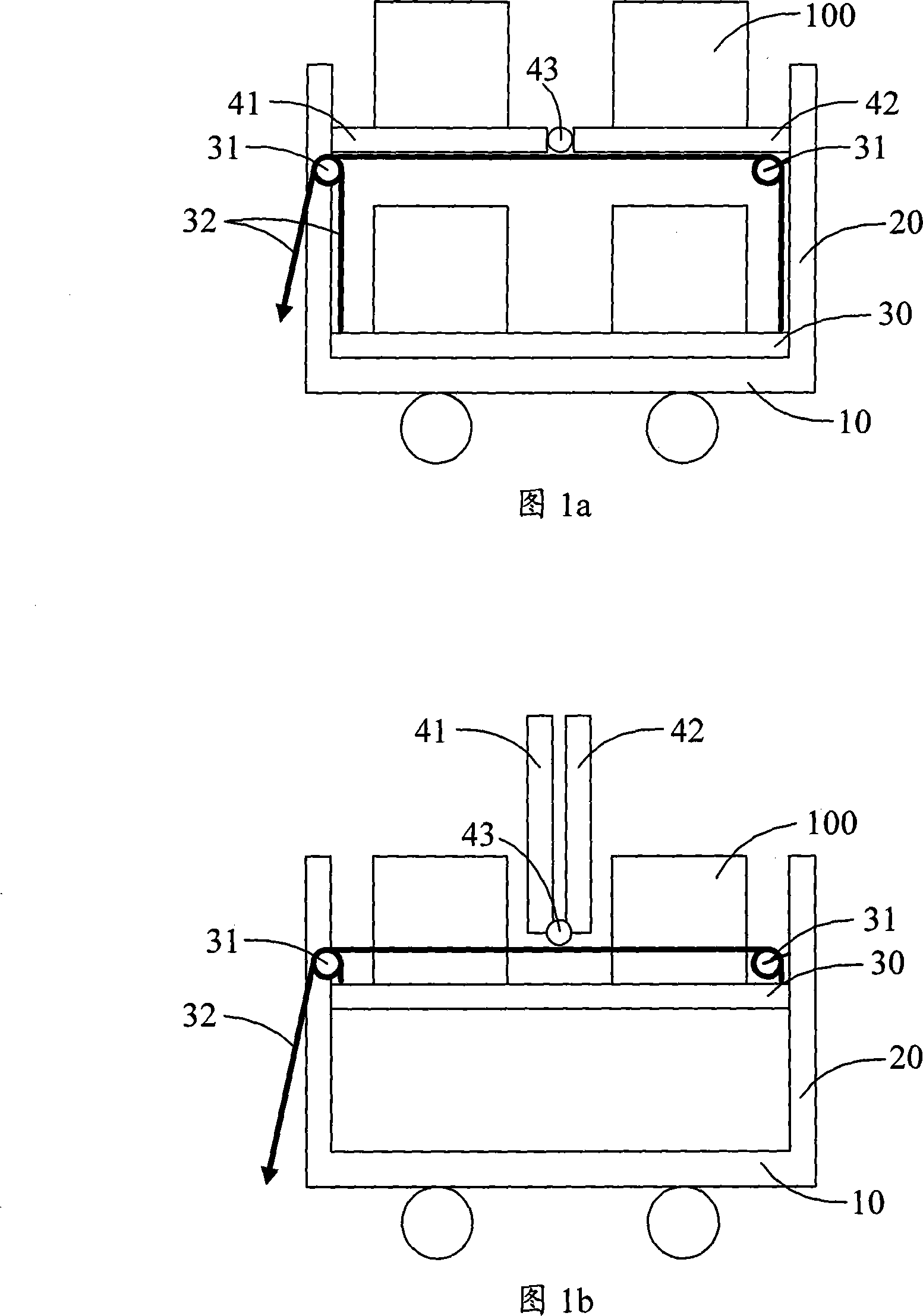

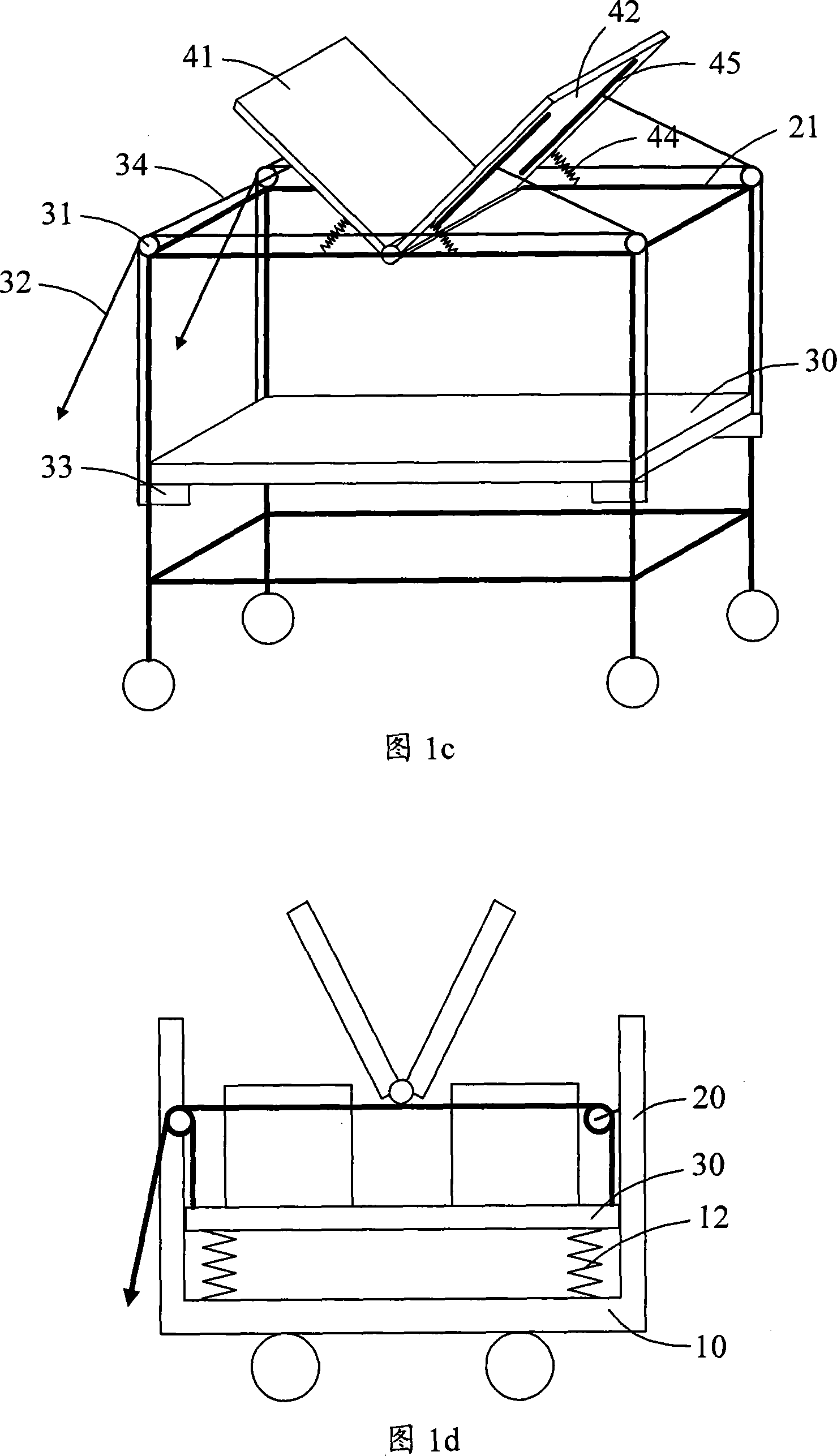

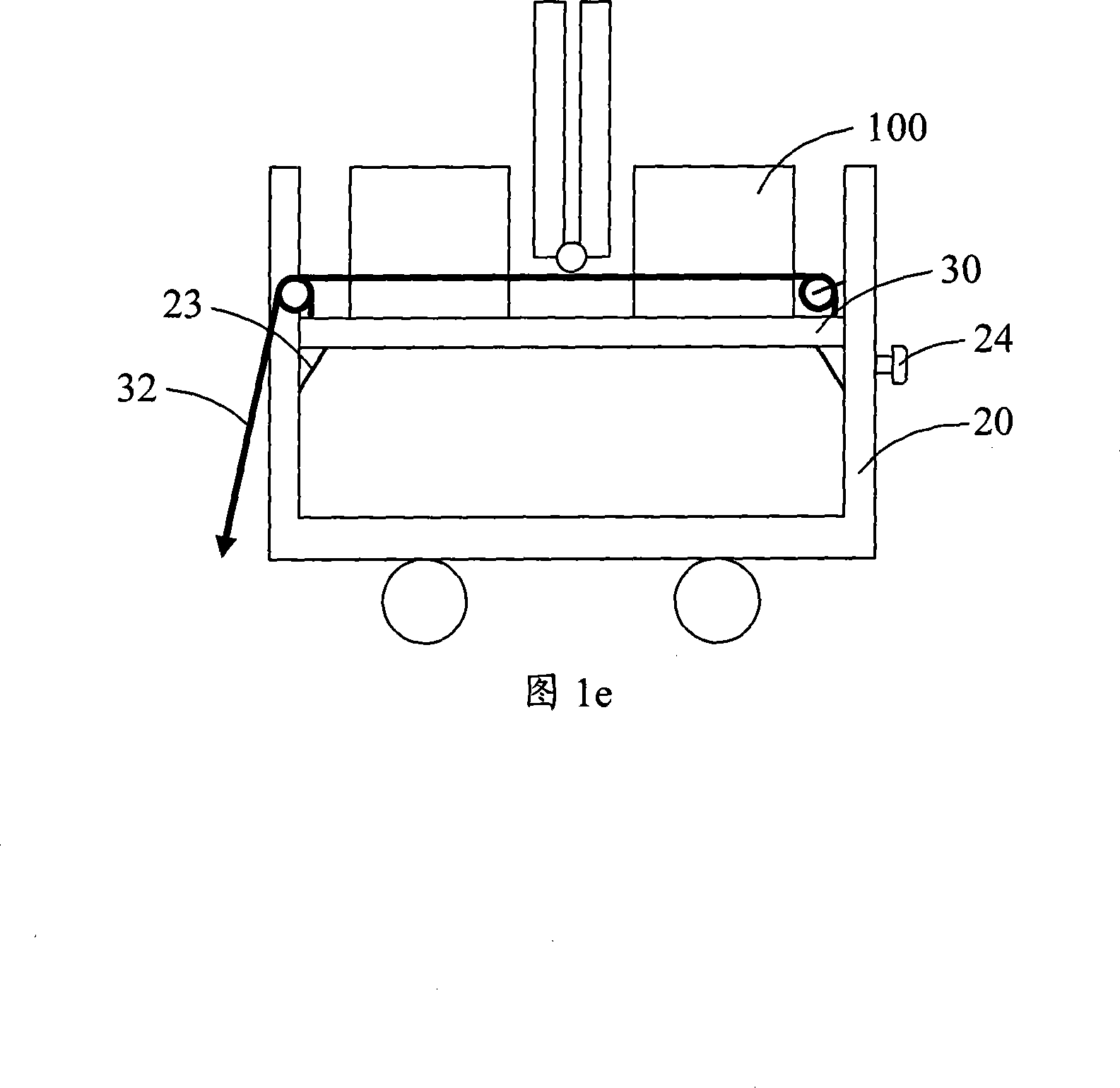

[0026] Referring to FIG. 1a to FIG. 1e , the wafer transportation vehicle of the present invention includes a base 10 , a body 20 and two shelves. The upper shelf is made up of two baffles 41, 42 and a shaft 43, the baffles 41, 42 are hinged to the shaft 43, and can rotate around the shaft 43 to an unfolded state (see Figure 1a) or a folded state ( See Figure 1b). FIG. 1a shows the unfolded state. In this state, a crystal box 100 can be respectively placed on the two baffles 41 and 42 . The lower shelf 30 is a movable shelf, and through the cooperation of the pulley 31 and the stay cord 32 , the lower shelf 30 can move up and down in the vehicle body 20 under the traction of the stay cord 32 .

[0027] After the crystal box 100 on the upper shelf is taken away by the operator, the crystal box 100 on the lower shelf 30 needs to be continuously accessed. Referring to FIG. 1 b , when the operator lifts the lower shelf 30 through the pull rope 32 , the baffles 41 and 42 rotate a...

Embodiment 2

[0032] Referring to Fig. 2a and Fig. 2b, the wafer transportation vehicle of the present embodiment is in the form of a trolley, which has a base 10' and a side body 20', the base 10' is provided with wheels 11', and the top of the body 20' is equipped with The hand push handle is 21', which is convenient for the operator to push the transport vehicle. The wafer transport vehicle is also provided with two layers of shelves: a lower shelf 30' and an upper shelf 40', and one end of the two-layer shelf can pass along the guide rail 22' on the vehicle body 20' through a pulley or a slider (see Figure 2b ) sliding, and the other ends are fixedly connected to each other through shelf pillars 31', and shelf fences 35' / 42' are respectively provided on each shelf, which are used to surround the crystal box in the area where the crystal box is placed, and prevent the crystal box from being placed on the shelf. The board fell off.

[0033] In this embodiment, power shears are used to re...

Embodiment 3

[0035] Referring to Fig. 3a to Fig. 3c, on the basis of Embodiment 2, the wafer transportation vehicle of this embodiment is changed into a structure in which only the lower shelf is lifted. Wherein, the transport vehicle base 10', the vehicle body 20', the lower shelf 30', the power shear 12' and its driving and fixing parts are all the same or similar to Embodiment 2, and its main improvement is the structure of the upper shelf 40'.

[0036] Referring to Fig. 3a, the upper shelf 40' is only composed of a frame, a front slide 43', a rear slide 44' and a central fixed frame 45' arranged on the frame, between the slides 43', 44' and the central fixed frame 45' It is hollow, and the front and rear sliding plates 43', 44' can slide toward or away from the central fixing frame 45' along the frame rails. Fig. 3 b is the side view of front and rear slide plate 43 ', 44 ' and central fixed mount 45 ', and the section of front and rear slide plate 43 ', 44 ' is triangular, and the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com