Construction for fixing outgoing line of radiating fan

A cooling fan and structure technology, which is applied to components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc., can solve the problems of wire 851 coming off, inconvenient assembly, and increased cost of cooling fans, etc. , to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be exemplified below in detail with reference to the accompanying drawings.

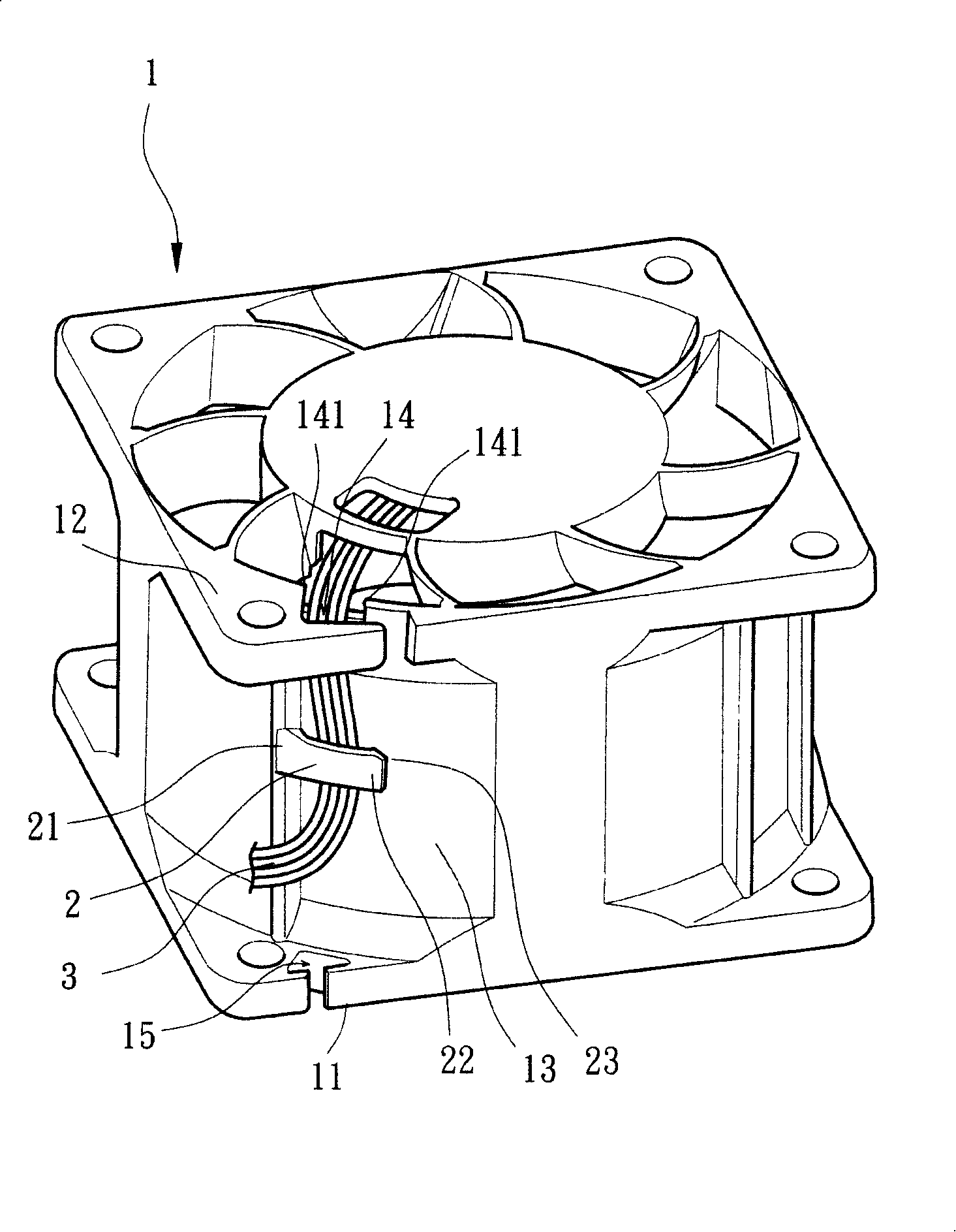

[0029] Please refer to image 3 As shown, it is the outlet fixing structure of a preferred embodiment of the present invention. The cooling fan housing 1 of this embodiment has a first end face 11 and a second end face 12, and between the first end face 11 and the second end face 12 A surrounding side wall 13 is provided, and a through groove 14 is provided on the second end face 12 itself, and the through groove 14 can pass through the second end face 12 for a wire 3 to pass through the second end face 12 and extend toward the side wall 13 . In addition, the through groove 14 is provided with two sides 141 , and the two sides 141 can limit the arbitrary displacement of the wire 3 .

[0030] please refer again image 3 , 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com