Method for eliminating CuxO resistance memory formation voltage

A resistance memory and voltage technology, applied in the field of microelectronics, can solve problems such as device performance degradation, no resistance conversion characteristics, and storage medium damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

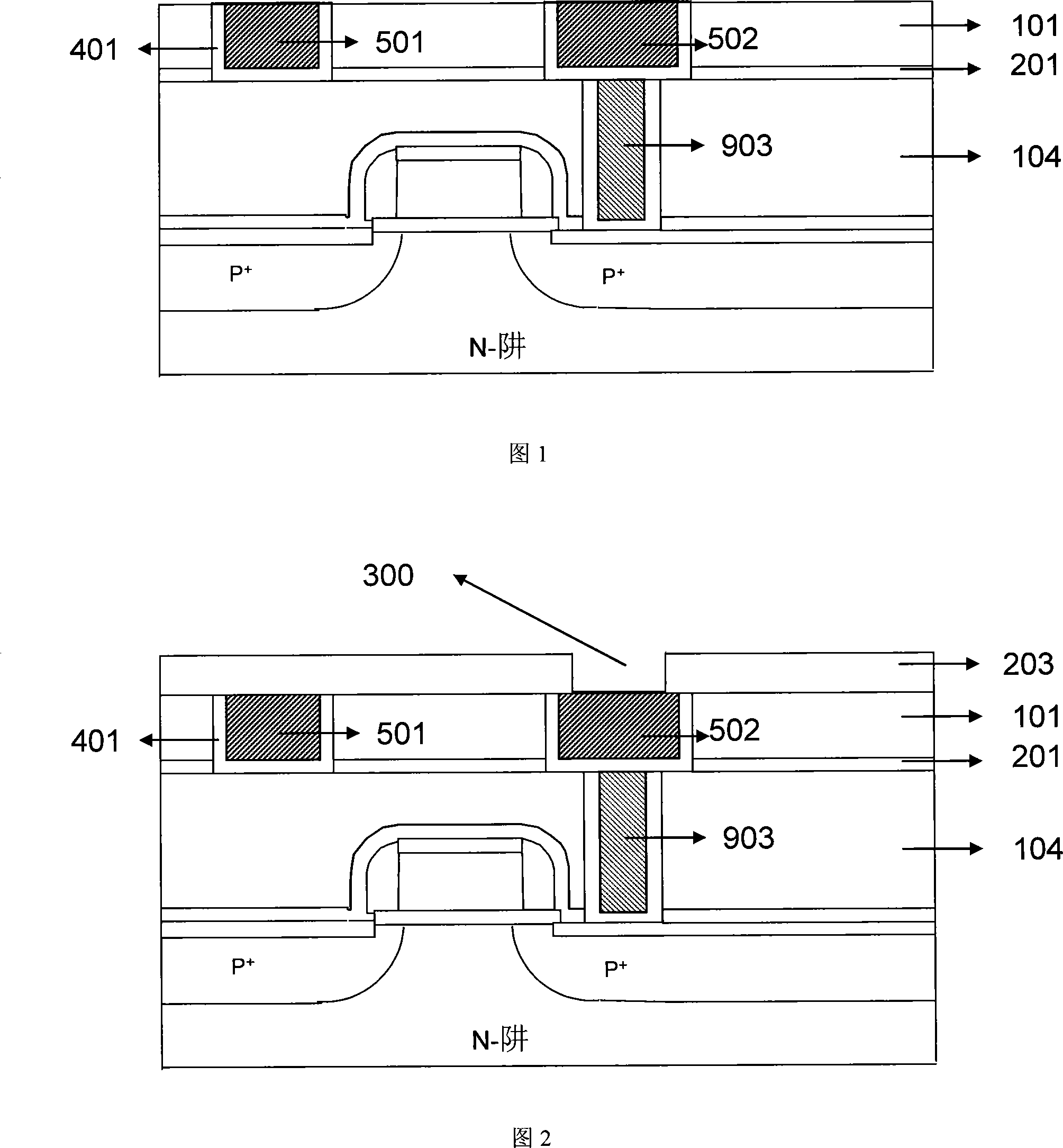

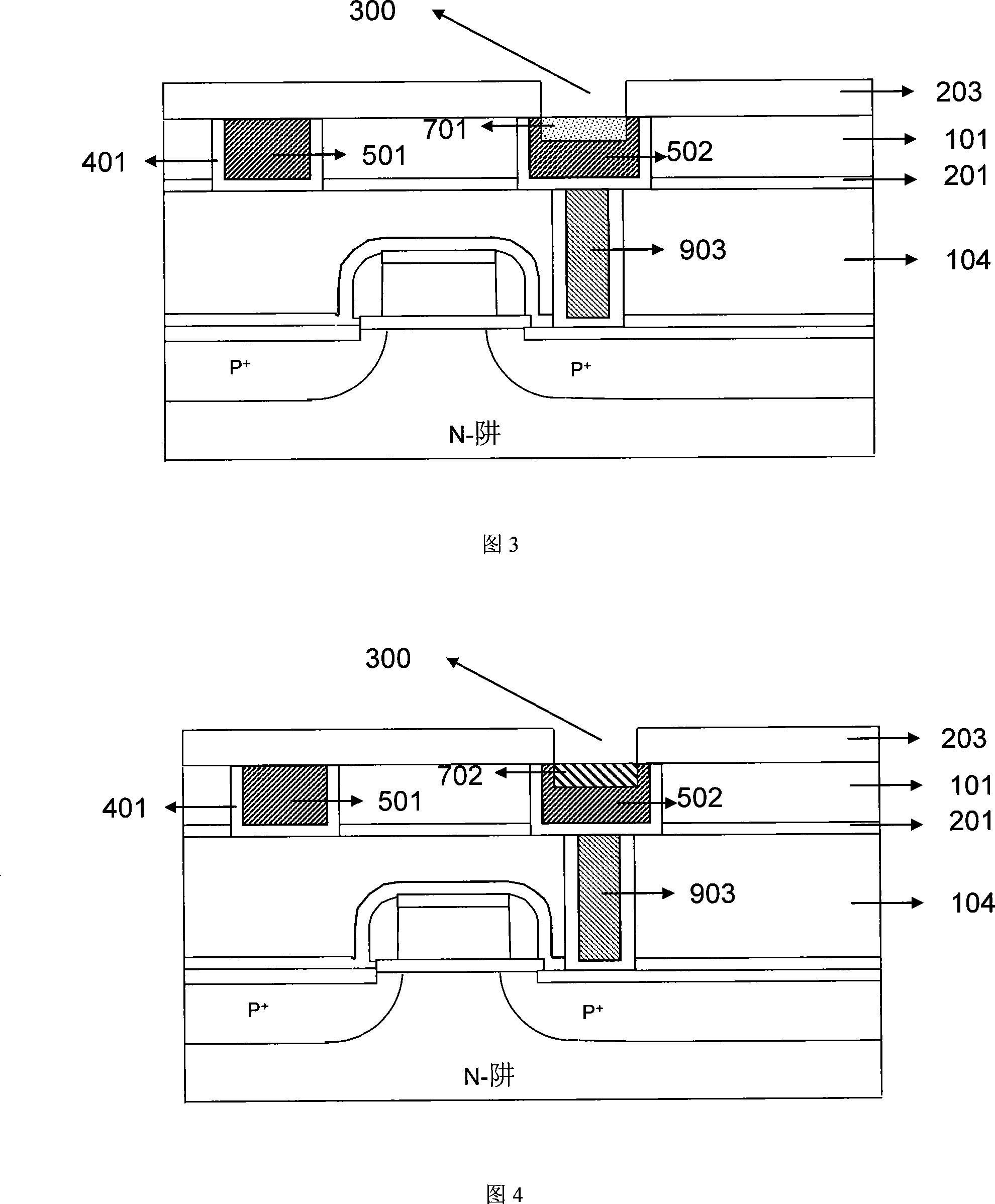

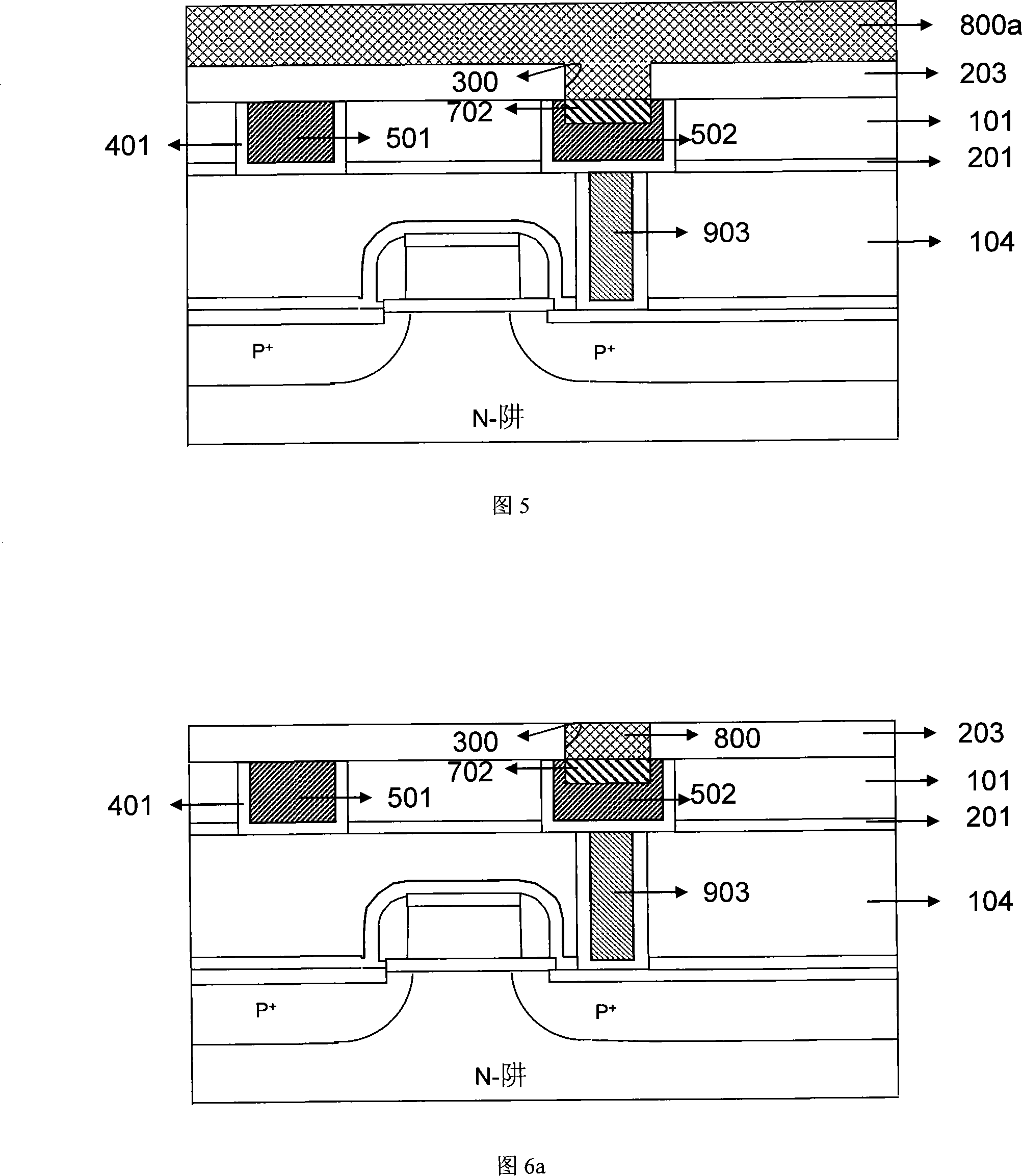

[0020] Hereinafter, the present invention will be more fully described in reference embodiments in conjunction with the drawings. The present invention provides preferred embodiments, but should not be considered as limited to the embodiments set forth herein. In the figure, the thickness of the layers and regions are enlarged for clarity, but as a schematic diagram, it should not be regarded as strictly reflecting the proportional relationship of geometric dimensions.

[0021] The reference figure here is a schematic diagram of an idealized embodiment of the present invention. The embodiment shown in the present invention should not be considered as limited to the specific shape of the area shown in the figure, but includes the resulting shape, such as caused by manufacturing. deviation. For example, the curve obtained by dry etching usually has the characteristics of bending or roundness, but in the illustrations of the embodiments of the present invention, they are all represe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com