Leak-proof cable connection sealing device

A sealing device and cable sealing technology, applied in the direction of cable entry sealing device, electromechanical device, electrical components, etc., can solve the problems of burning out the motor, poor sealing and wrapping at the joint, unsafe leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

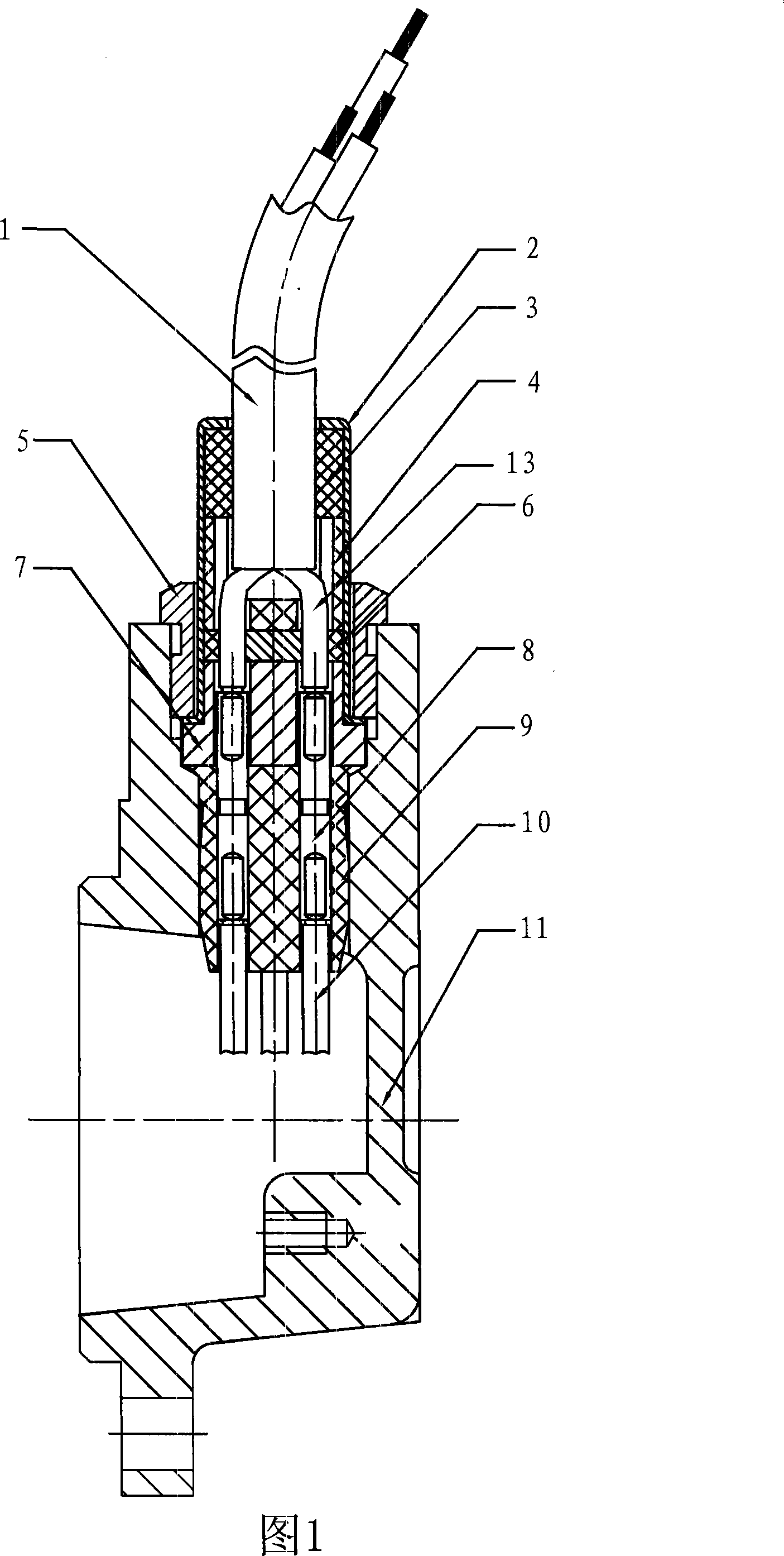

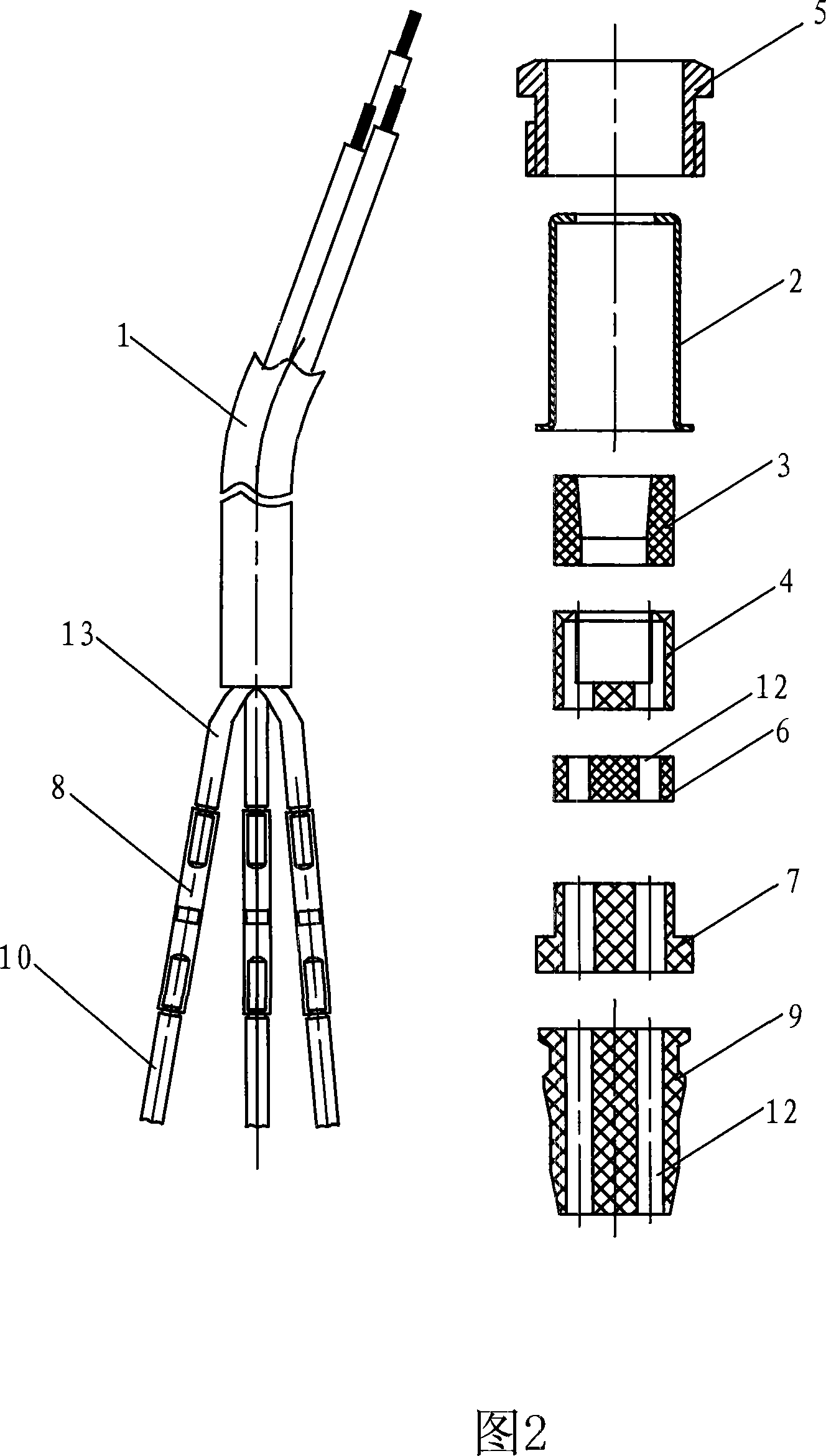

[0025] As shown in FIGS. 1 and 2 , the leakage-proof cable connection sealing device of the present invention includes a cable 1 , a junction box cover 11 , a hollow copper bolt 5 and a steel sleeve 2 . The hollow copper bolt 5 matches the inner hole of the junction box cover 11 . The steel sleeve 2 is set in the hollow copper bolt 5, and a layer of cable sealing ring 3 is extruded between the steel sleeve 2 and the cable line 1.

[0026] As shown in Figures 1 and 2, there are several core wires 13 in the cable 1, and a layer of core wire sealing ring 6 is arranged outside the core wire 13. The core wire sealing ring 6 has several threading holes 12, and the core wire 13 All pass through the threading hole 12. There is also a support 4 between the core wire sealing ring 6 and the cable sealing ring 3. The upper end of the support 4 is pressed against the cable sealing ring 3, and the lower end is pressed on the core wire sealing ring 6. The support 4 is opposite to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com