Brake device or safety clamp for protecting temporary elevator safety space

A technology of braking device and safe space, applied in the direction of brake type, transportation and packaging, elevator, etc., it can solve the problems of complexity, safety gear device cannot be re-released by remote control, and cannot ensure uniform pressure on the guide rail, etc., so as to reduce wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

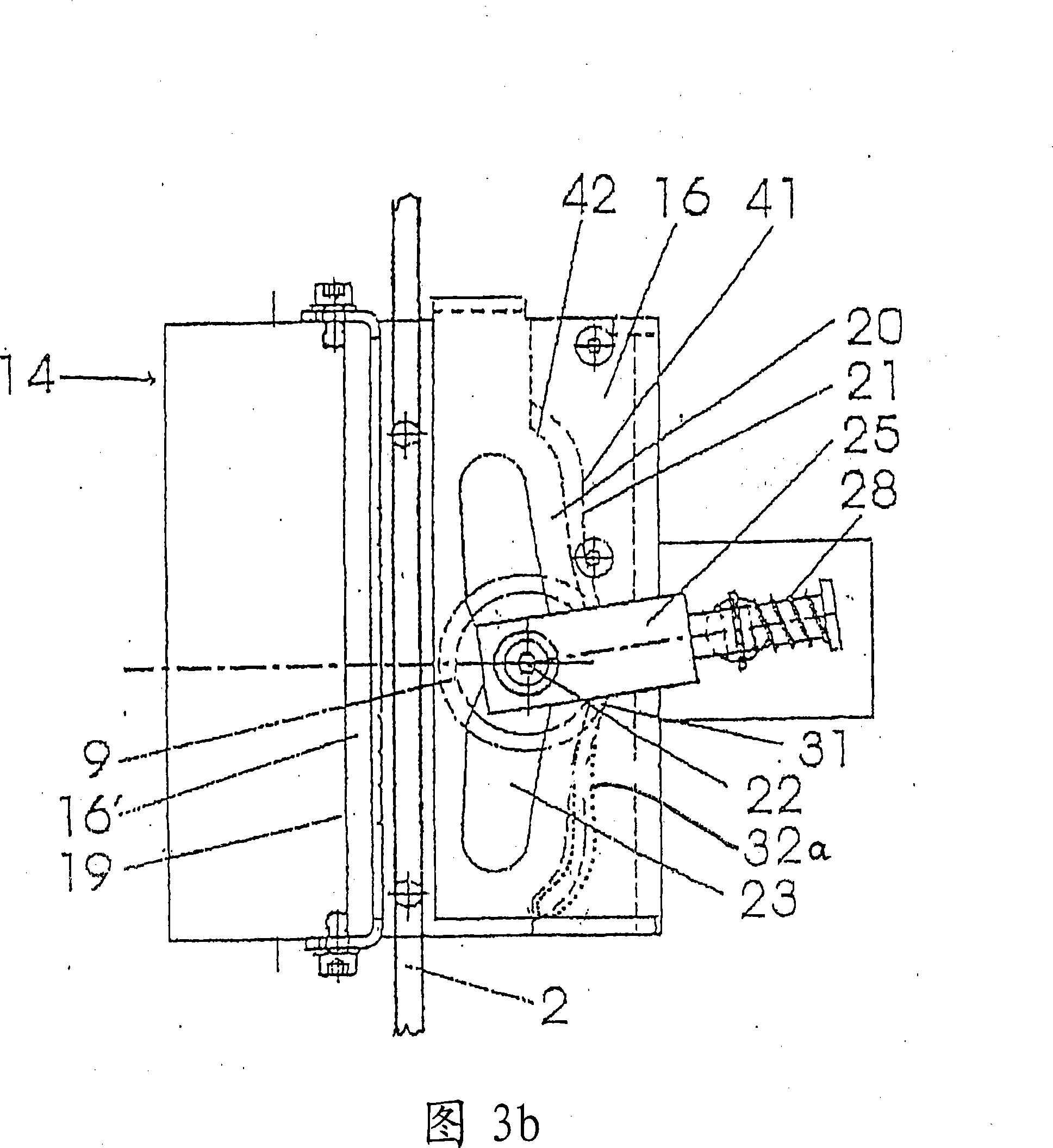

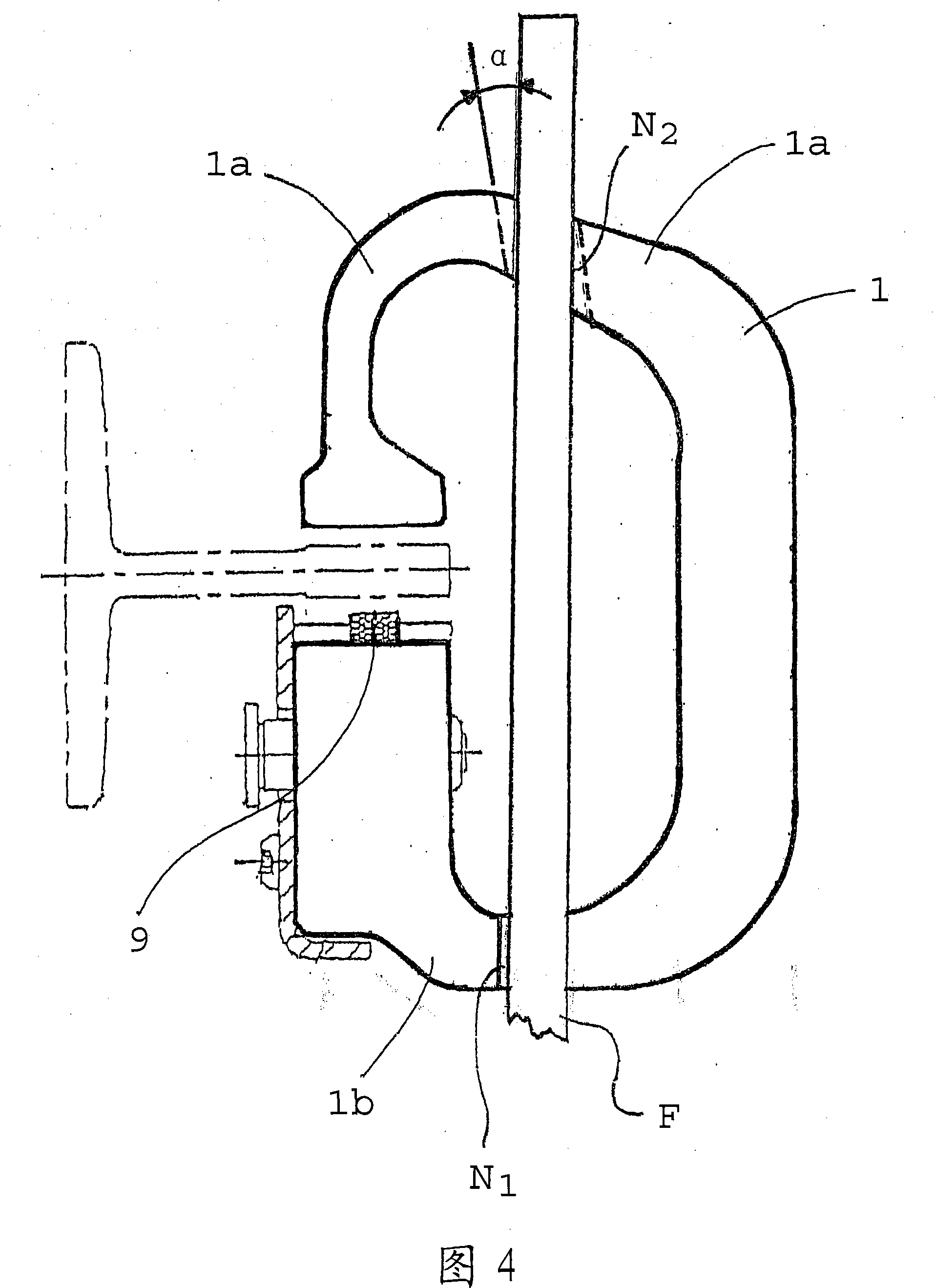

[0045] As shown in FIG. 2 , the guide rail 2 has a rail head 8 connected to the rail foot via a web 6 .

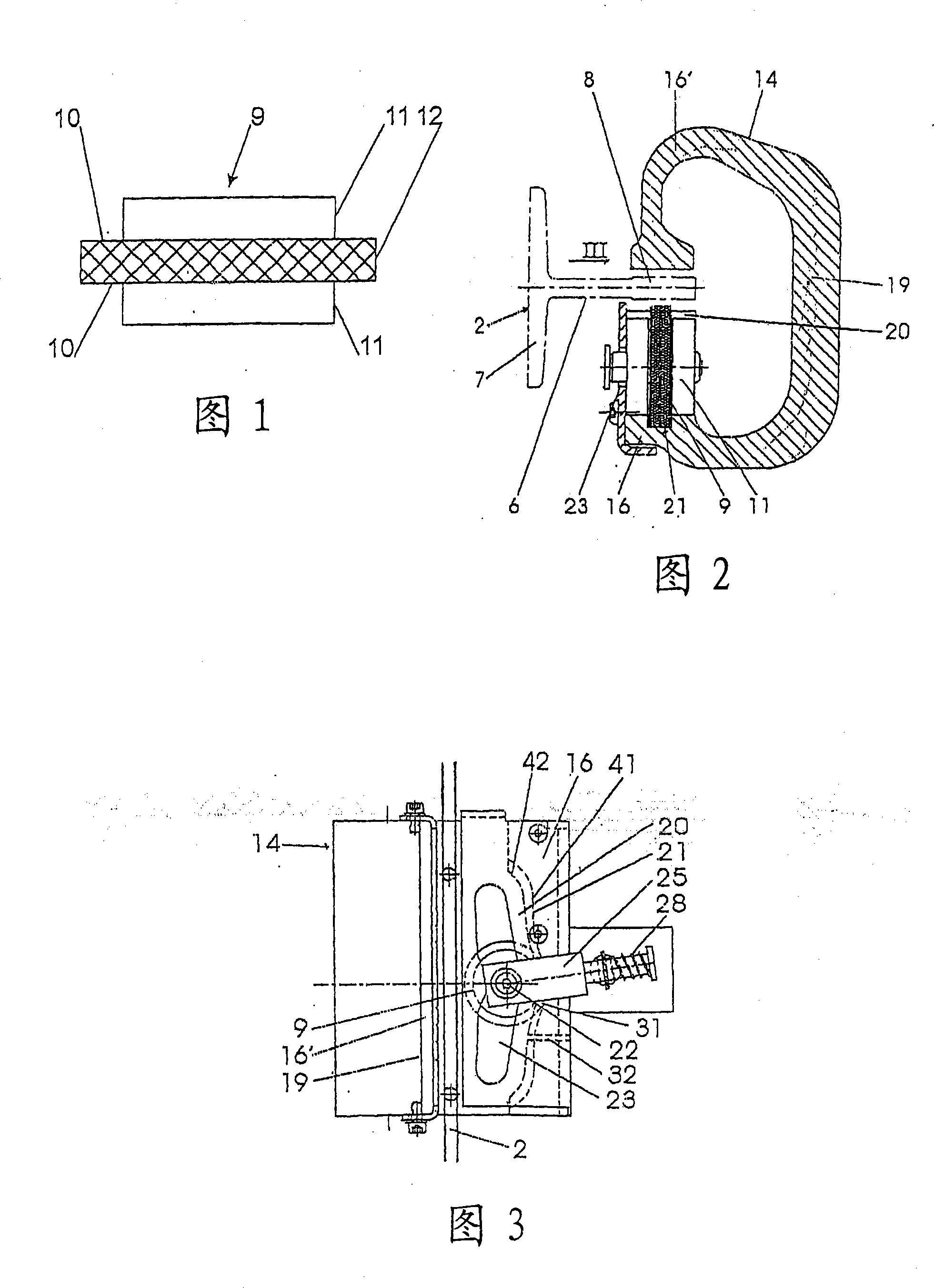

[0046] In the braking device or safety gear according to the invention, a braking mechanism in the form of a roller 9 is provided which is provided with shoulders 11 on its end faces 10 (see FIG. 1 ). The outer peripheral surfaces of the rollers 9 function as friction surfaces 12 . For this purpose, the rollers have knurls or friction layers, which are used to make contact with the guide rail (see FIG. 2 ).

[0047] FIG. 2 shows the brake device 14 according to the invention in horizontal section. The braking device 14 has a caliper body 19, which is essentially a U-shaped profile, and the two legs 16, 16' have guide rails 2 in the region of their free ends. On the legs 16 of the pliers body 19 there are slots 20 in which the rollers 9 run. Furthermore, the slot 20 has a groove 21 which can accommodate the friction surface 12 of the roller 9 (see FIG. 1 ). The body of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com