Blast balance apparatus

An air volume balance and valve body technology, applied in chemical instruments and methods, dispersed particle filtration, sliding valves, etc., can solve the problems of butterfly valve dust removal pipeline scouring, insignificant effect, large flow resistance, etc., to eliminate noise and reduce adhesion. , the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

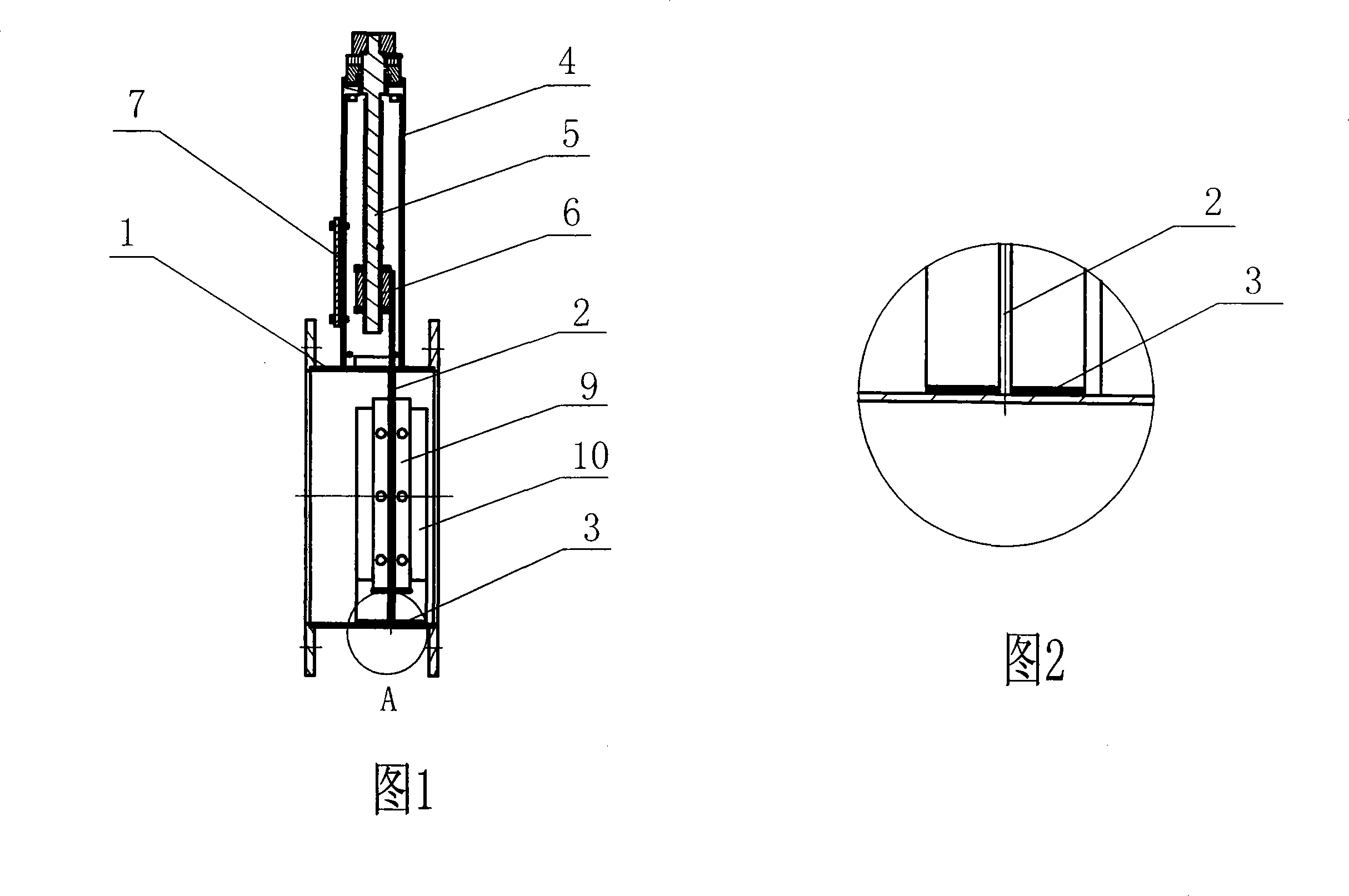

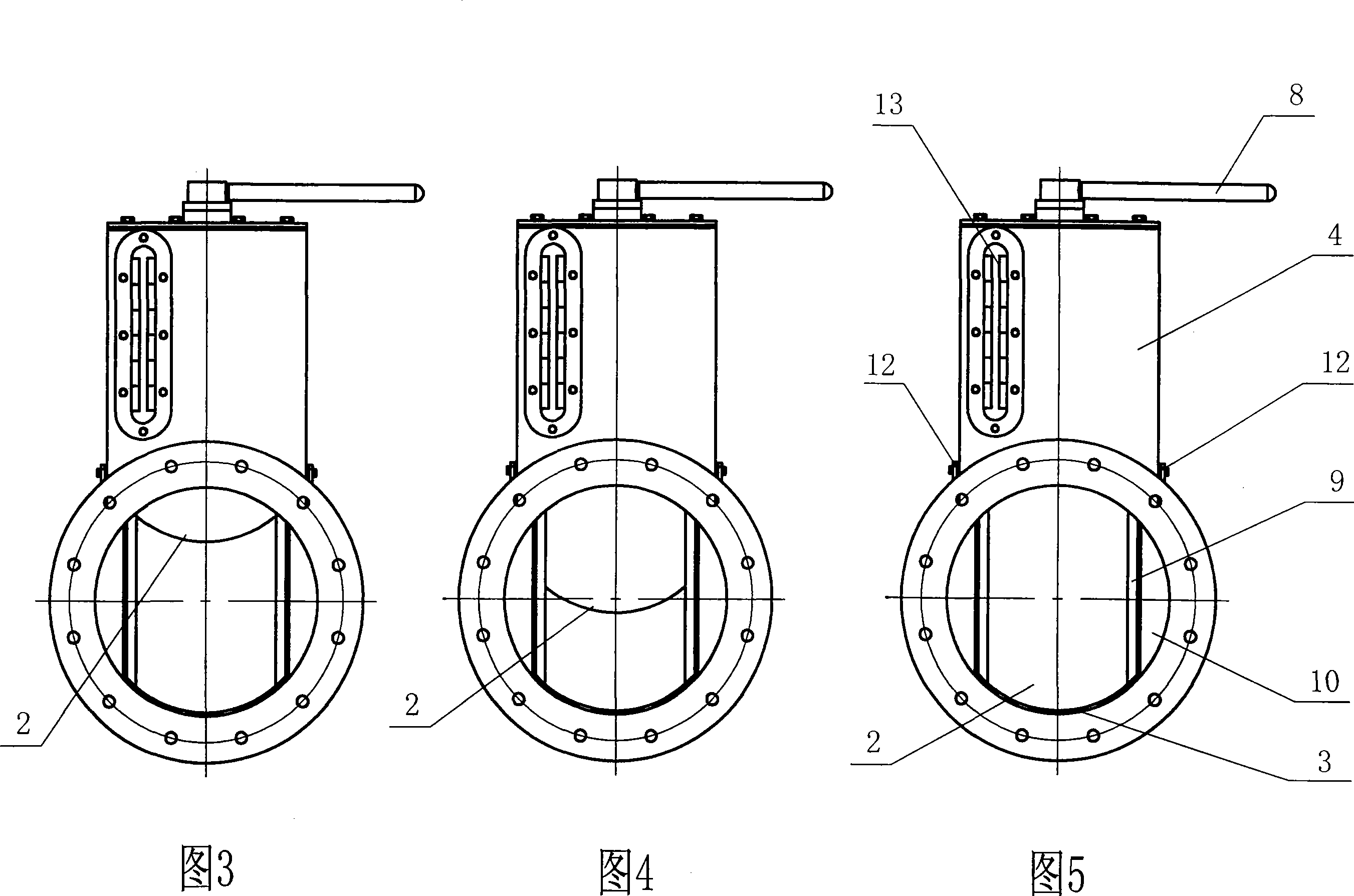

[0024] As shown in Fig. 1 and Fig. 2, the air volume balancer of the present invention includes a valve body 1, a transmission device installed on the valve body 1, and an inserting plate 2 connected with the transmission device and capable of moving up and down. A wear-resistant liner 3 is provided on the inner wall of the valve body 1 corresponding to the lower end of the inserting plate 2 . When the inserting plate 2 is in a fully closed state, the inserting plate 2 and the wear-resistant liner 3 are sealingly engaged. The wear-resistant liner 3 can be a high-density polytetrafluoroethylene liner, or other clean, smooth and wear-resistant liners. In the present invention, the valve body 1 is cylindrical, the bottom end of the inserting plate 2 is arc-shaped with the same shape as the cylindrical valve body, and the wear-resistant l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com