Method for cutting simulation artificial diamond

A cutting method and artificial diamond technology, applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problems of insufficient fineness, poor luminosity, large polygonal surface area, etc., and achieve easy operation and cutting method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

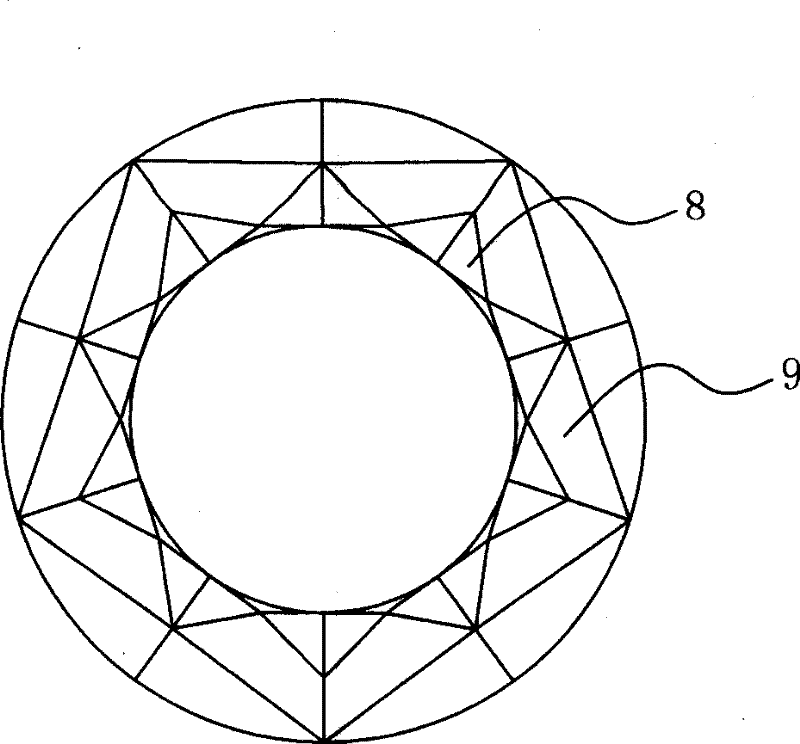

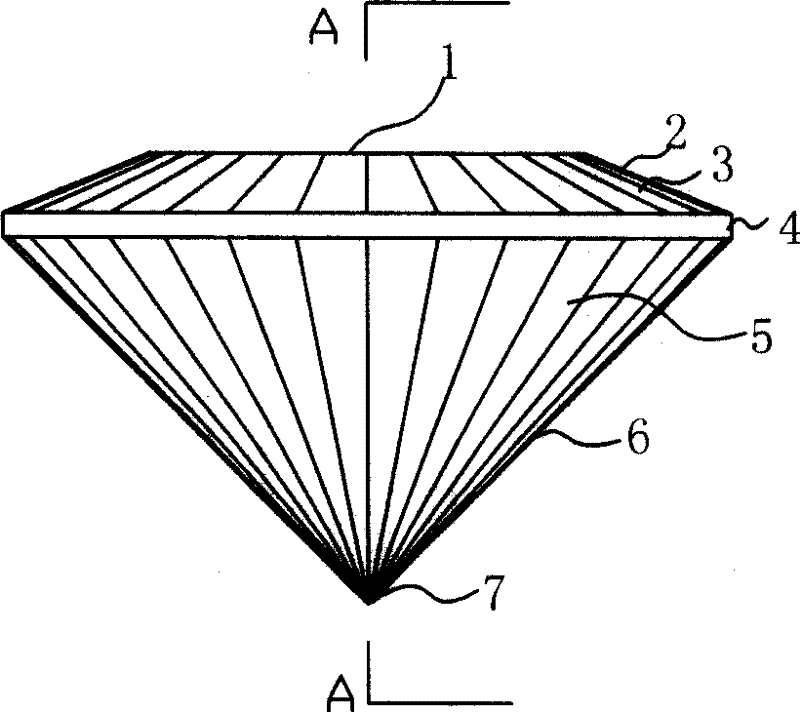

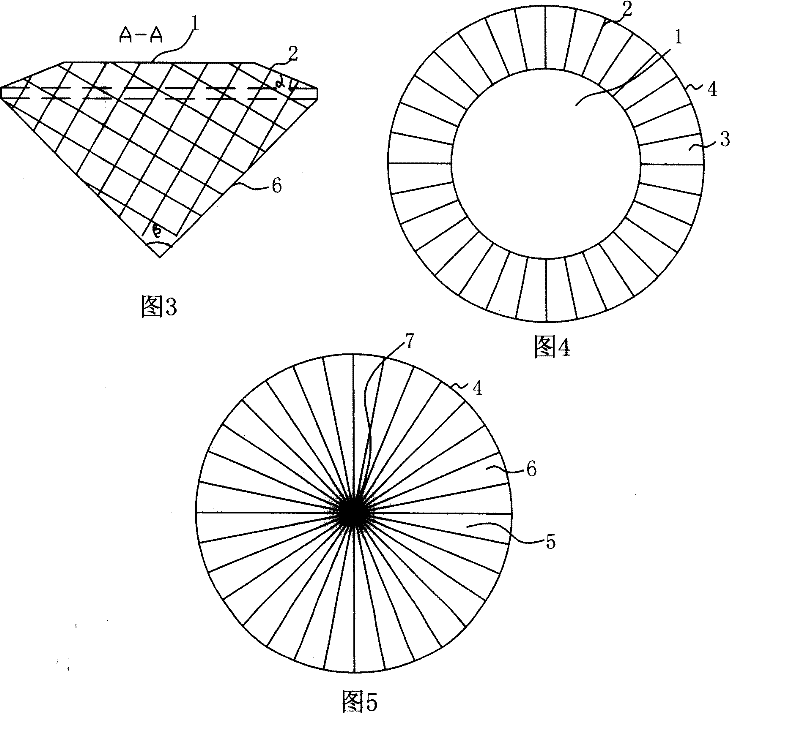

[0028] As shown in the figure, a cutting method for imitating artificial diamonds uses zirconium silicate (zirconia) as the raw material; carries out billeting and taking out materials; From top to bottom, it includes the convex crown 2, the edge 4 and the protruding part 6. The thickness of the edge 4 is generally 0.5mm; then the cutting surface grinding mainly includes the following process:

[0029] ① Cut the edge part 4 into a perfect circular smooth closed ring; as Figure 2-Figure 5 shown.

[0030] ② Take the point of the protruding part 6 located on the centerline of the edge part 4 as the sharp point 7, and take the sharp point 7 as the center point on the side of the protruding part 6 to make 32 equally divided cutting planes 5, and the adjacent cutting planes The bisectors on both sides of 5 are shared respectively, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com