Stainless steel sheet processing method

A stainless steel and thin plate technology, which is applied in the direction of special decorative structures, metal material coating technology, and the technology used to produce decorative surface effects, etc., can solve the problems of high environmental requirements and expensive calendering molds, and achieve high production efficiency , not easy to wear, simple processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

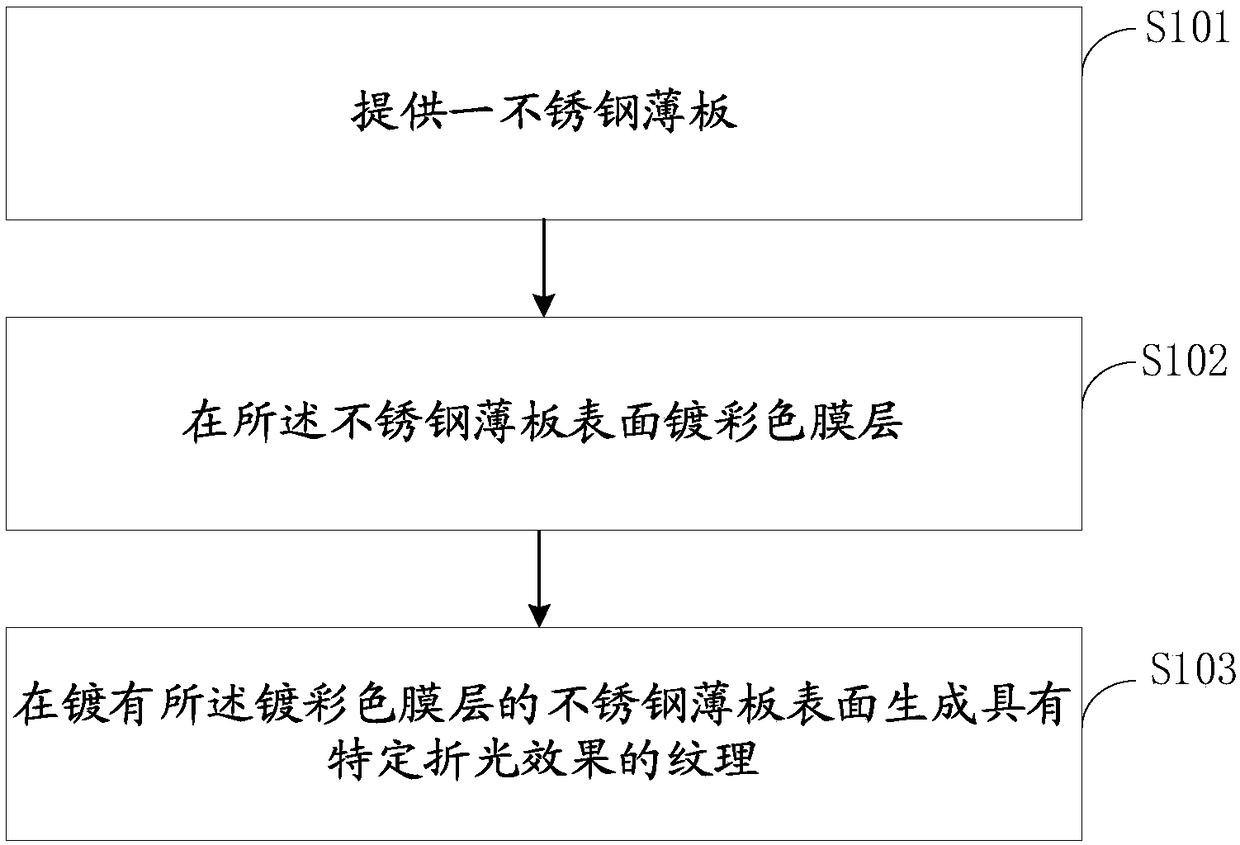

[0030] see figure 1 , this embodiment provides a method for processing a stainless steel sheet, the steps include steps S101-S103. The steps S101-S103 will be described below.

[0031] Step S101: providing a thin stainless steel plate.

[0032] Process the stainless steel sheet material into a stainless steel sheet of the desired shape, for example, when a square stainless steel sheet is required, a square stainless steel sheet is formed by cutting. Stainless steel sheets of different shapes can be processed according to different requirements, such as rhombus, circle, star, etc. For this, the example of a square stainless steel sheet should not be understood as a limitation of the present application.

[0033] Step S102: Coating a colored film layer on the surface of the stainless steel sheet.

[0034] Optionally, the stainless steel thin plate is put into a vacuum ion plating equipment, and a layer of colored film is plated on the surface of the stainless steel thin plate...

no. 2 example

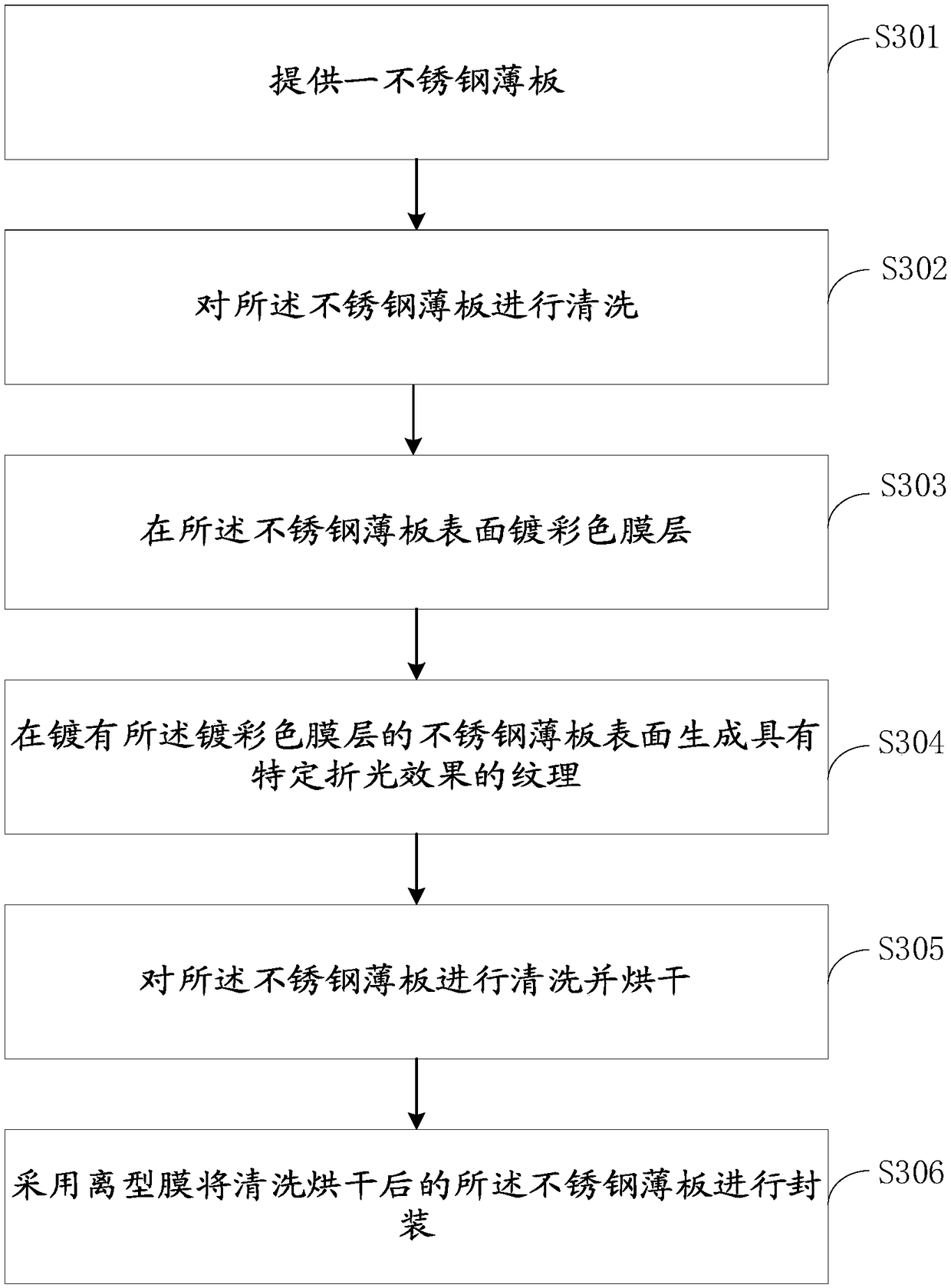

[0053] Please refer to image 3 , another step of processing a stainless steel sheet will be described below, and the steps include: steps S301-S306.

[0054] Step S301: providing a thin stainless steel plate.

[0055] For the same part, reference may be made to step S101 in the first embodiment, and to avoid redundancy, no further description is given here.

[0056] Step S302: cleaning the thin stainless steel plate.

[0057] see Figure 4 , Optionally, after providing a thin stainless steel plate, the stainless steel thin plate may also be cleaned, the steps include: steps S401-S402.

[0058] Step S401: Soak the stainless steel sheet in deionized water for a specific time.

[0059] Soak the stainless steel sheet with a specific shape cut in the above steps in deionized water for a specific time, the soaking time is 1 to 5 minutes, it can be understood that the soaking time is not limited to 1 to 5 minutes, for example, it can be the same as 6 Minutes, or 7 minutes, etc....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com