Shell assembly, manufacturing method thereof and electronic equipment

A shell component and shell technology, which is applied in the direction of shell/cabinet/drawer components, optics, instruments, etc., can solve the problem that the shell cannot meet the growing demand, achieve bright colors, meet The effect of using demand and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

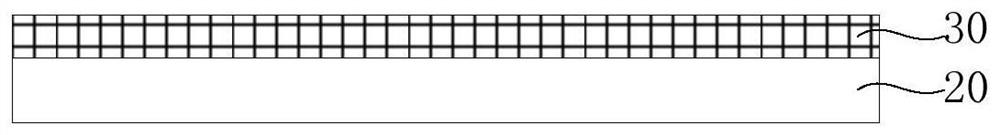

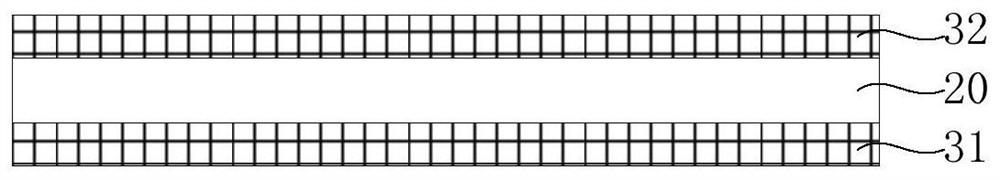

[0100] like Figure 15 As shown, in this embodiment, the housing assembly 100 includes a housing substrate 20 and two protective layers 24 . Wherein, the shell base material 20 includes a base body 21 , an adhesive layer 23 and two liquid crystal cells 22 . The matrix 21 is a composite plate of the PMMA layer 211 and the PC layer 212 , and the PMMA layer 211 has a predetermined color. Two liquid crystal units 22 are bonded to the PC layer 212 side and the PMMA layer 211 side of the substrate 21 respectively through the bonding layer 23, each liquid crystal unit 22 includes an alignment layer 222 and a liquid crystal layer 221, and the liquid crystal layer 221 is arranged on the corresponding A side of the alignment layer 222 facing the substrate 21 . The two protective layers 24 are respectively located on the sides of the two liquid crystal cells 22 away from the substrate 21 .

Embodiment 2

[0102] like Figure 16 As shown, in this embodiment, the housing assembly 100 includes a housing substrate 20 and two protective layers 24 . Wherein, the shell base material 20 includes a base body 21 , an adhesive layer 23 and two liquid crystal cells 22 . The matrix 21 is a composite plate of the PMMA layer 211 and the PC layer 212 , and the PC layer 212 has a predetermined color. Two liquid crystal units 22 are bonded to the PC layer 212 side and the PMMA layer 211 side of the substrate 21 respectively through the bonding layer 23, each liquid crystal unit 22 includes an alignment layer 222 and a liquid crystal layer 221, and the liquid crystal layer 221 is arranged on the corresponding A side of the alignment layer 222 facing the substrate 21 . The two protective layers 24 are respectively located on the sides of the two liquid crystal cells 22 away from the substrate 21 .

Embodiment 3

[0104] like Figure 17 As shown, in this embodiment, the housing assembly 100 includes a housing substrate 20 and two protective layers 24 . Wherein, the shell base material 20 includes a base body 21 , an adhesive layer 23 and two liquid crystal cells 22 . Wherein, the matrix 21 is a composite plate of the PMMA layer 211 and the PC layer 212 , and both the PMMA layer 211 and the PC layer 212 have preset colors. The two liquid crystal cells 22 are respectively bonded to the PC layer 212 side and the PMMA layer 211 side of the substrate 21 through the bonding layer 23, each liquid crystal cell 22 includes an alignment layer 222 and a liquid crystal layer 221, and the liquid crystal layer 221 is arranged on the alignment layer 222 facing the side of the base 21 . The two protective layers 24 are respectively located on the sides of the two liquid crystal cells 22 away from the substrate 21 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com