Variable colorful cigarette tipping paper

A technology of tipping paper and cigarettes, which is applied in the field of cigarette production and can solve problems such as monotony and no cigarette tipping paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

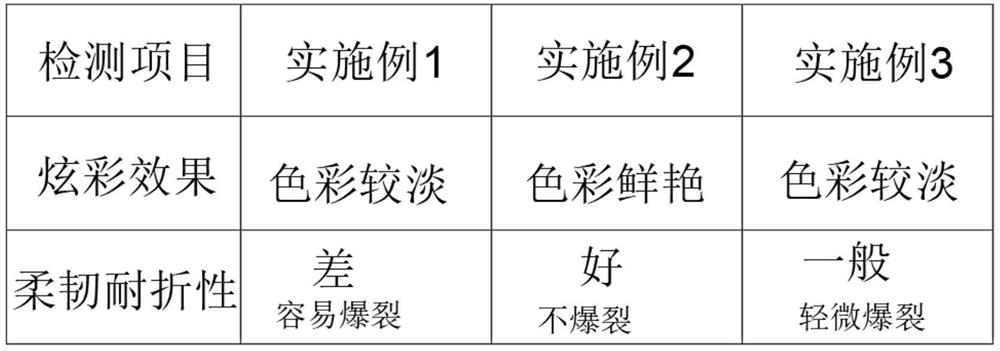

Examples

Embodiment 1

[0033] The invention provides a variable colorful cigarette tipping paper, which has the advantages of colorful effect and good flexibility, and includes fiber pulp, calcium carbonate filler, titanium dioxide, combustion enhancer, color powder and water-based acrylic resin. The parts by mass are:

[0034] 77 parts of fiber pulp;

[0035] 10 parts of calcium carbonate filler;

[0036] 2 parts of titanium dioxide;

[0037] 1 part of combustion aid;

[0038] 5 copies of color powder;

[0039] 5 parts of water-based acrylic resin;

[0040] Further, the following preparation steps are also included:

[0041] S1, a practical stirring tank is used to stir the fiber pulp clockwise under normal temperature and pressure, and the stirring time is 30 minutes to make a pulp with a beating degree of 20°SR;

[0042] S2, the calcium carbonate filler is added in the stirred tank twice, and the time interval between the two additions is 5 minutes;

[0043] S3, adding titanium dioxide and...

Embodiment 2

[0054] The invention provides a variable colorful cigarette tipping paper, which has the advantages of colorful effect and good flexibility, and includes fiber pulp, calcium carbonate filler, titanium dioxide, combustion enhancer, color powder and water-based acrylic resin. The parts by mass are:

[0055] 83 parts of fiber pulp;

[0056] 13 parts of calcium carbonate filler;

[0057] 3 parts of titanium dioxide;

[0058] 2 parts of combustion aid;

[0059] 8 parts of color powder;

[0060] 8 parts of water-based acrylic resin;

[0061] Further, the following preparation steps are also included:

[0062] S1, a practical stirring tank is used to stir the fiber pulp clockwise under normal temperature and pressure, and the stirring time is 45 minutes to make a pulp with a beating degree of 23°SR;

[0063] S2, the calcium carbonate filler is added in the stirred tank twice, and the time interval between the two additions is 7 minutes;

[0064] S3, adding titanium dioxide and c...

Embodiment 3

[0075] The invention provides a variable colorful cigarette tipping paper, which has the advantages of colorful effect and good flexibility, and includes fiber pulp, calcium carbonate filler, titanium dioxide, combustion enhancer, color powder and water-based acrylic resin. The parts by mass are:

[0076] 90 parts of fiber pulp;

[0077] 15 parts of calcium carbonate filler;

[0078] 5 parts of titanium dioxide;

[0079] 3 parts of combustion aid;

[0080] 10 copies of color powder;

[0081] 10 parts of water-based acrylic resin;

[0082] Further, the following preparation steps are also included:

[0083] S1, a practical stirring tank is used to stir the fiber pulp clockwise under normal temperature and pressure, and the stirring time is 60 minutes to make a pulp with a beating degree of 25°SR;

[0084] S2, the calcium carbonate filler is added in the stirred tank twice, and the time interval between the two additions is 8 minutes;

[0085] S3, adding titanium dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com