Regeneration method of ink-jet printer cartridge

A technology of inkjet printers and ink cartridges, applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve environmental pollution and other problems, and achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

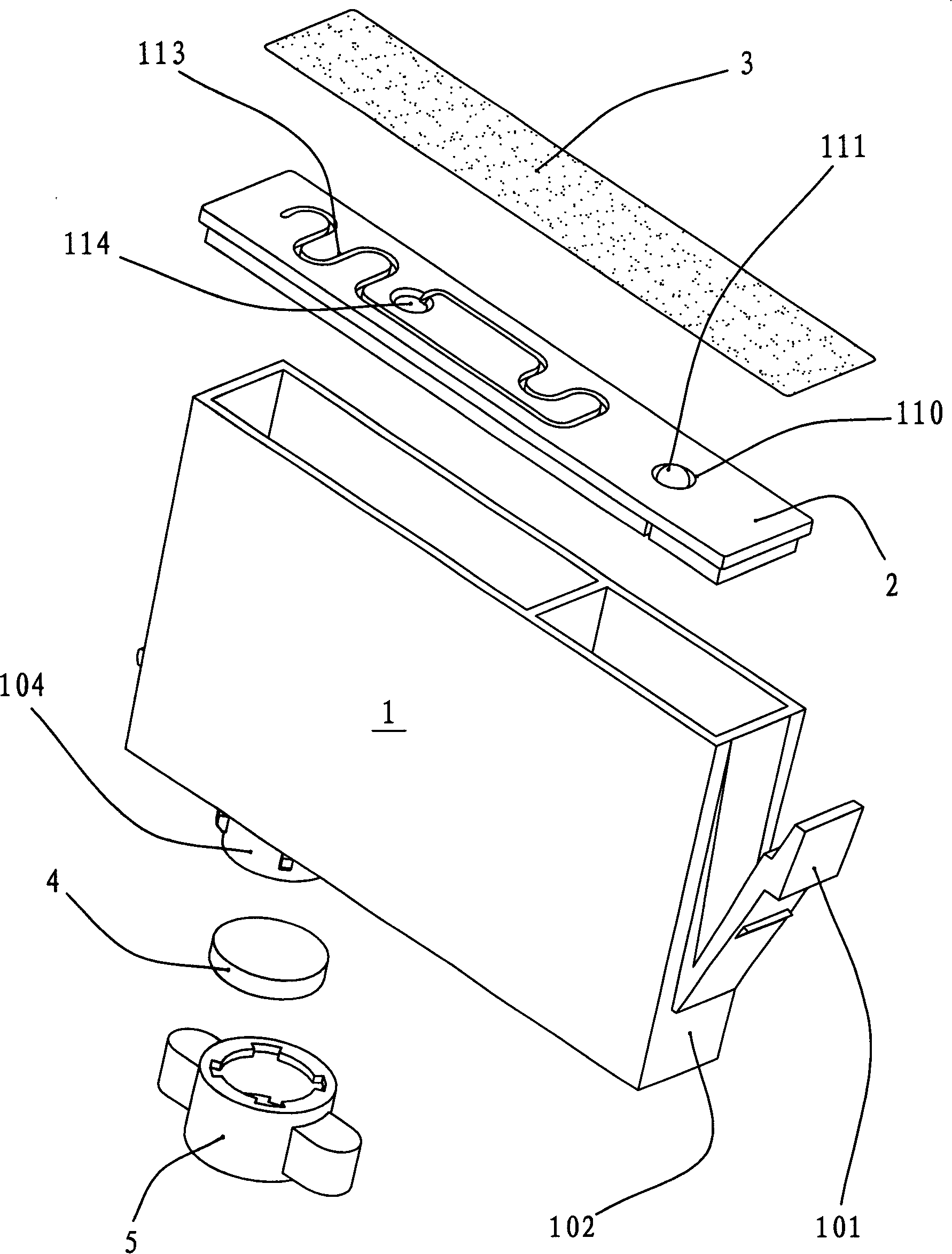

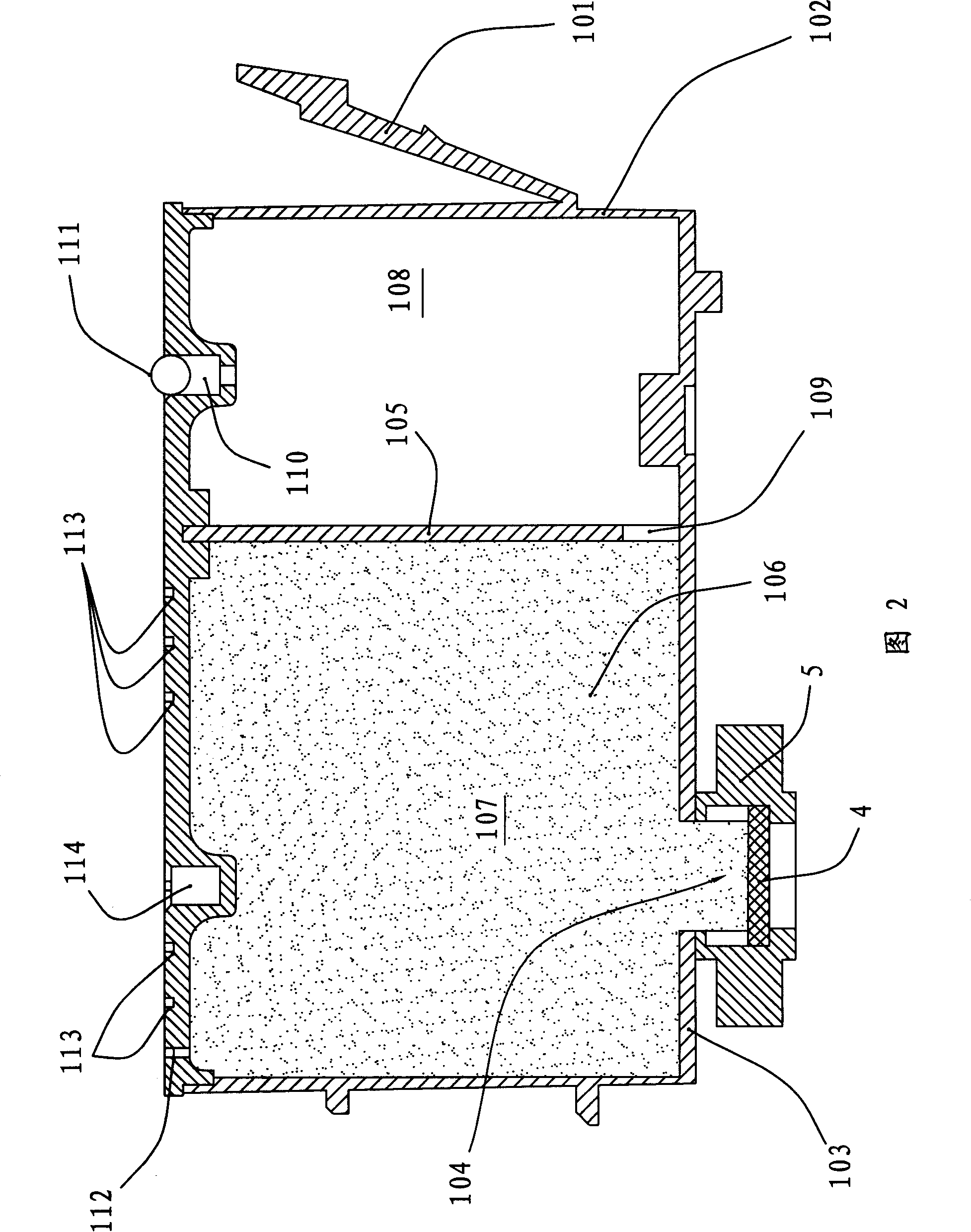

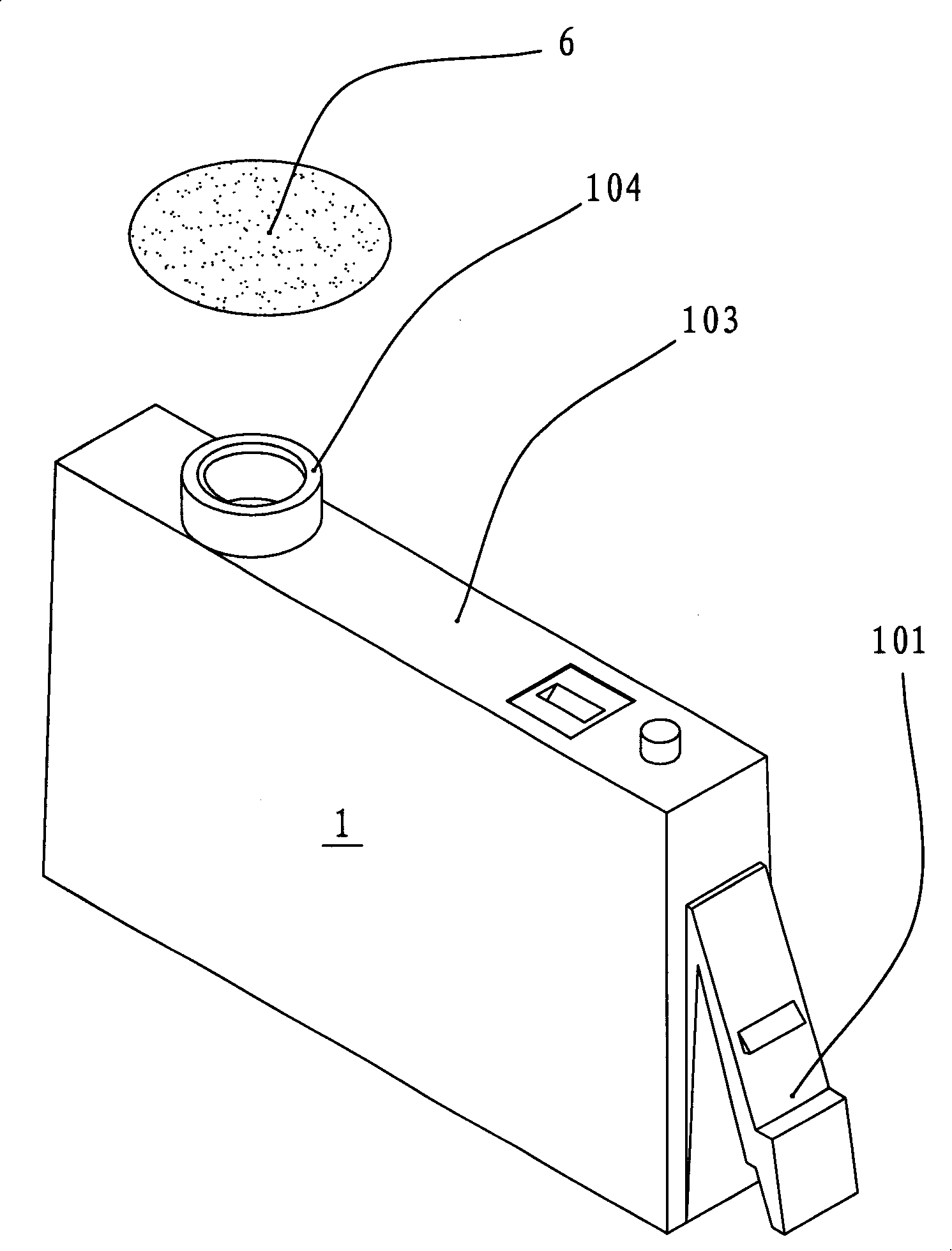

[0029] figure 1 , 2, and 3 are the first embodiment of the structure of the ink cartridge processed by the method for regenerating the ink cartridge of the inkjet printer of the present invention. figure 1 2. The placement posture of the ink cartridge in 2 corresponds to or is the same as the placement posture under the working state. image 3 The placement posture of the middle ink cartridge is basically opposite to the placement posture under its working state.

[0030] see figure 1 , 2. The ink cartridge targeted by the present invention mainly includes a box body 1 and a box cover 2 structurally.

[0031] The appearance of the box body 1 is about a flat cuboid. Its interior is a cavity formed by surrounding five side walls of the box body 1 . Its narrower and longer side wall, that is, the top wall is in an open state.

[0032] An elastic support handle 101 protruding obliquely from one end of the long side of the outer surface to the opposite end is arranged on the o...

Embodiment 2

[0048] For the ink-jet printer cartridge with the structure of the above-mentioned embodiment 1, it may also be considered to adopt a simpler regeneration method for processing. The simple method flow is as follows:

[0049] Firstly, use a drill or a crowbar to remove the glue sealing ball 111 and open the ink filling port 110 .

[0050] Afterwards, use the clip 7 (see Figure 4 ) fasten the ink supply port 104 so that it is sealed.

[0051] Subsequently, ink is injected into the ink storage chamber 108 to a rated capacity through the ink filling port 110 .

[0052] Finally, seal the ink filling port 110 with a new glue sealing ball, that is, obtain the regenerated ink cartridge.

[0053] The qualification rate of ink cartridges recovered by the method reaches over 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com