Method for preparing isopropyl benzene hydrogen peroxide by catalytically oxidizing isopropyl benzene

A technology of cumene hydroperoxide and cumene, which is applied to the preparation of peroxygen compounds, chemical instruments and methods, and the preparation of organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

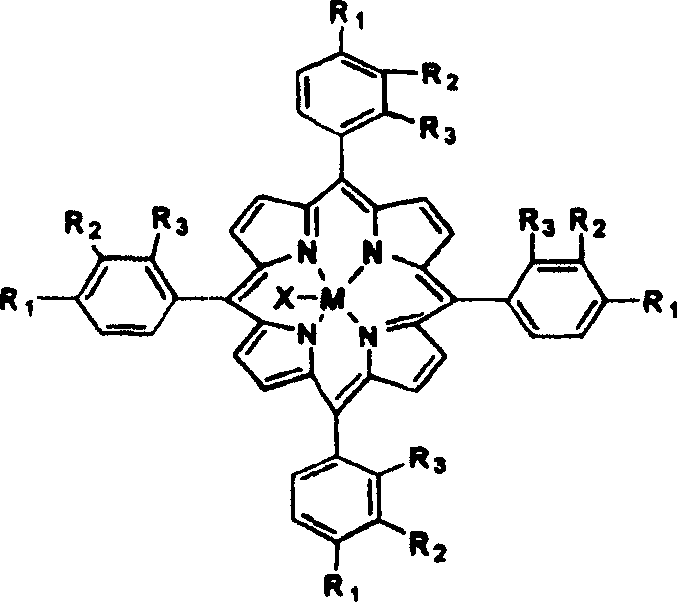

[0012] 1 mg of metalloporphyrins with general formula (1) structure, R 1 = Cl, R 2 = R 3 =H, M=Mn, X=Cl, add into 150ml of cumene, and feed air with an absolute pressure of 0.1MPa at a flow rate of 600ml / min. The reaction was stirred at 110°C for 4 hours, the yield of cumene hydroperoxide was 24.9%, and the selectivity was 94.5%. However, in the non-catalyzed oxidation process without metal porphyrin under this condition, the yield of cumene hydroperoxide is only 2.4%, and the selectivity is 96.1%.

Embodiment 2

[0014] With 2mg of metalloporphyrins with general formula (1) structure, R 1 = Cl, R 2 = R 3 =H, M=Fe, X=Cl, add into 300ml of cumene, and feed air with an absolute pressure of 0.1MPa at a flow rate of 500ml / min. The reaction was stirred at 110° C. for 4 hours, the yield of cumene hydroperoxide was 20.6%, and the selectivity was 96.0%. In the non-catalyzed oxidation process without adding metal porphyrins under this condition, the yield of cumene hydroperoxide is only 2.2%, and the selectivity is 96.5%.

Embodiment 3

[0016] The metalloporphyrin that 5mg has general formula (1) structure is dissolved in the 150ml cumene, R 1 = Cl, R 2 = R 3 =H, M=Mn, feed the air with absolute pressure of 0.1MPa with 600ml / min gas velocity, reactant 3 hours under 120 ℃, cumene hydroperoxide productive rate is 38.85%, and selectivity is 90.5%. However, in the non-catalyzed oxidation process without adding metal porphyrins under this condition, the yield of cumene hydroperoxide is only 2.9%, and the selectivity is 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com