Glass liner steel tube applications

A technology for lining steel pipes and glass, used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of large surface roughness of steel pipes, wax accumulation in pipes, and non-smoothness, so as to solve the problem of wax accumulation and save money. Thermal energy, the effect of wide application prospects

Inactive Publication Date: 2008-08-06

吉林石油集团有限责任公司 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, in the late stage of development of old oilfields, the oil outlet temperature at the wellhead is low. In the alpine region, wax deposits are most likely to form in the pipeline. The use of normal temperature transportation needs to solve the problem of wax deposits and condensation in the pipeline. Conventional oil collection pipelines are mostly steel pipes. The absolute roughness of the steel pipe surface is relatively large, not smooth, and it is easy to accumulate wax. Therefore, in order to overcome this problem, a new type of pipe material is used—glass lining the inner wall of the steel pipe to form a glass-lined steel pipe.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

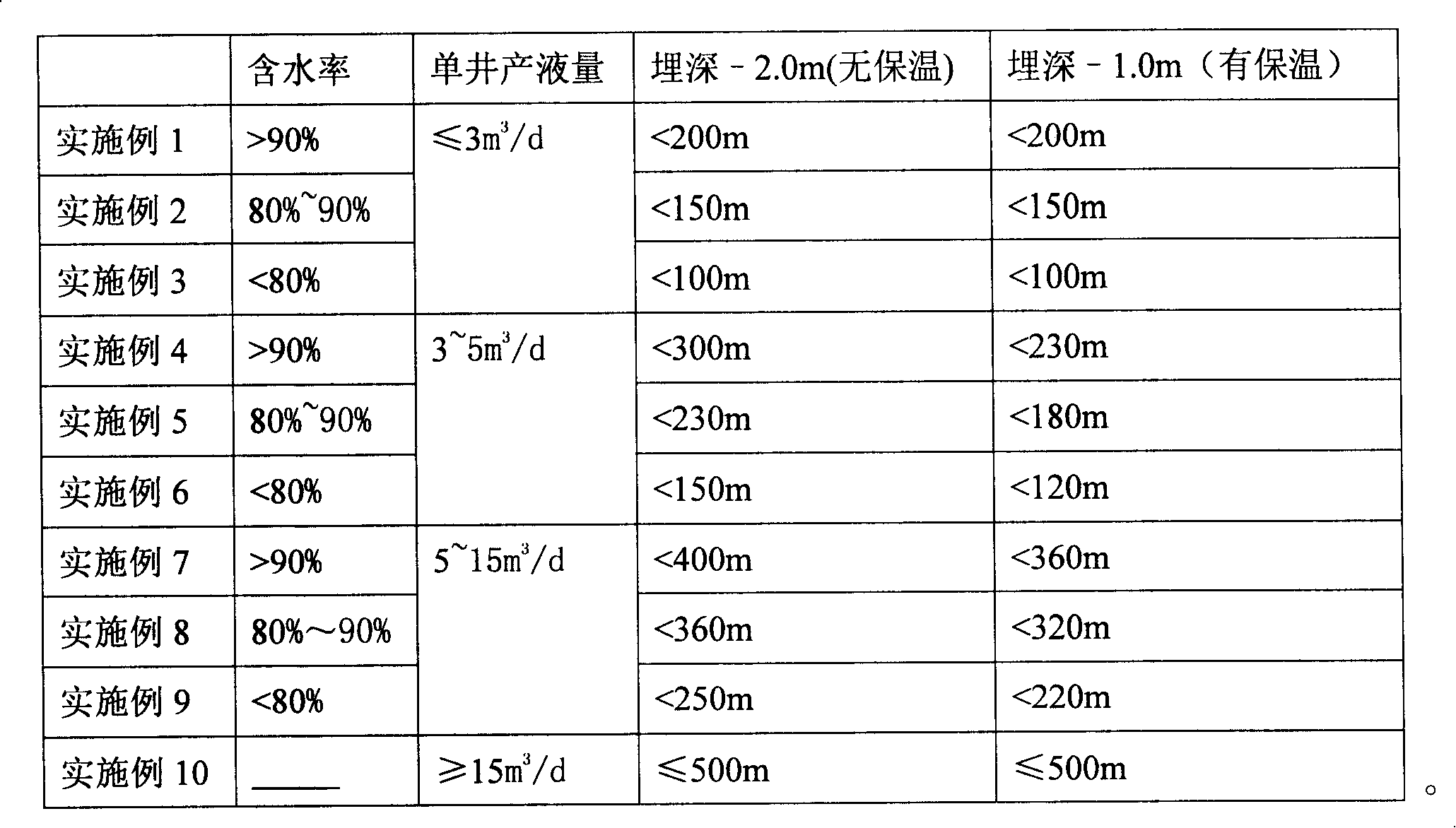

Embodiment 1~10

[0019]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Application of a steel pipe with glass lining relates to the steel pipe with glass lining used in delivery pipelines of produced liquid of oil wells. The steel pipes with glass lining are used as the delivery pipelines of the produced liquid of the oil wells for delivering the produced liquid of the oil wells, wherein the produced liquid of the oil wells contains water with ratio of 60%-100%, the delivery temperature is normal temperature, and single pipes of the steel pipes with glass lining delivers the produced liquid of the oil wells. The gathering and transporting technique of the delivery at normal temperature of the glass lining is perfect in application effect, which effectively resolves the problem of deposited paraffin and realizes delivery at normal temperature. The gathering and transporting at normal temperature is realized by employing the steel pipe of glass lining, namely the produced liquid of the oil well need no additional heat source. The produced liquid is delivered at normal-temperature state by employing the dump energy of the oil wells, which can save a large amount of heat energy and electrical energy. The technique is a deciding factor for guaranteeing the delivery at normal temperature to be realized with extremely wide application prospect and remarkable benefits of energy conservation and consumption reduction.

Description

technical field [0001] The invention relates to the application of a glass-lined steel pipe, in particular to a transmission pipeline for the glass-lined steel pipe used in oil well production. Background technique [0002] The transportation of oil well production fluid is an important link in oilfield production. Three-pipe heat-tracing transportation and double-pipe hot water transportation are commonly used. In the later stage of water-bearing development, the water content in the oil well production fluid is relatively high, with an average of more than 75%, and sometimes reaching 80-90%. Using the above two processes is only for heating a large amount of water produced, which is uneconomical and unreasonable. Contents of the invention [0003] In order to overcome the uneconomical shortcomings of the current oil well production liquid transportation link, simplify the oil collection process and reduce energy consumption; change from three pipes and double pipes to si...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F17D1/08

Inventor 孙锐艳石少敏王亚林陈彦军

Owner 吉林石油集团有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com