Lens structure and light emitting unit

A lens structure and lens technology, applied in semiconductor devices, optics, light sources, etc. of light-emitting elements, to achieve improved light diffusion effects and good light diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

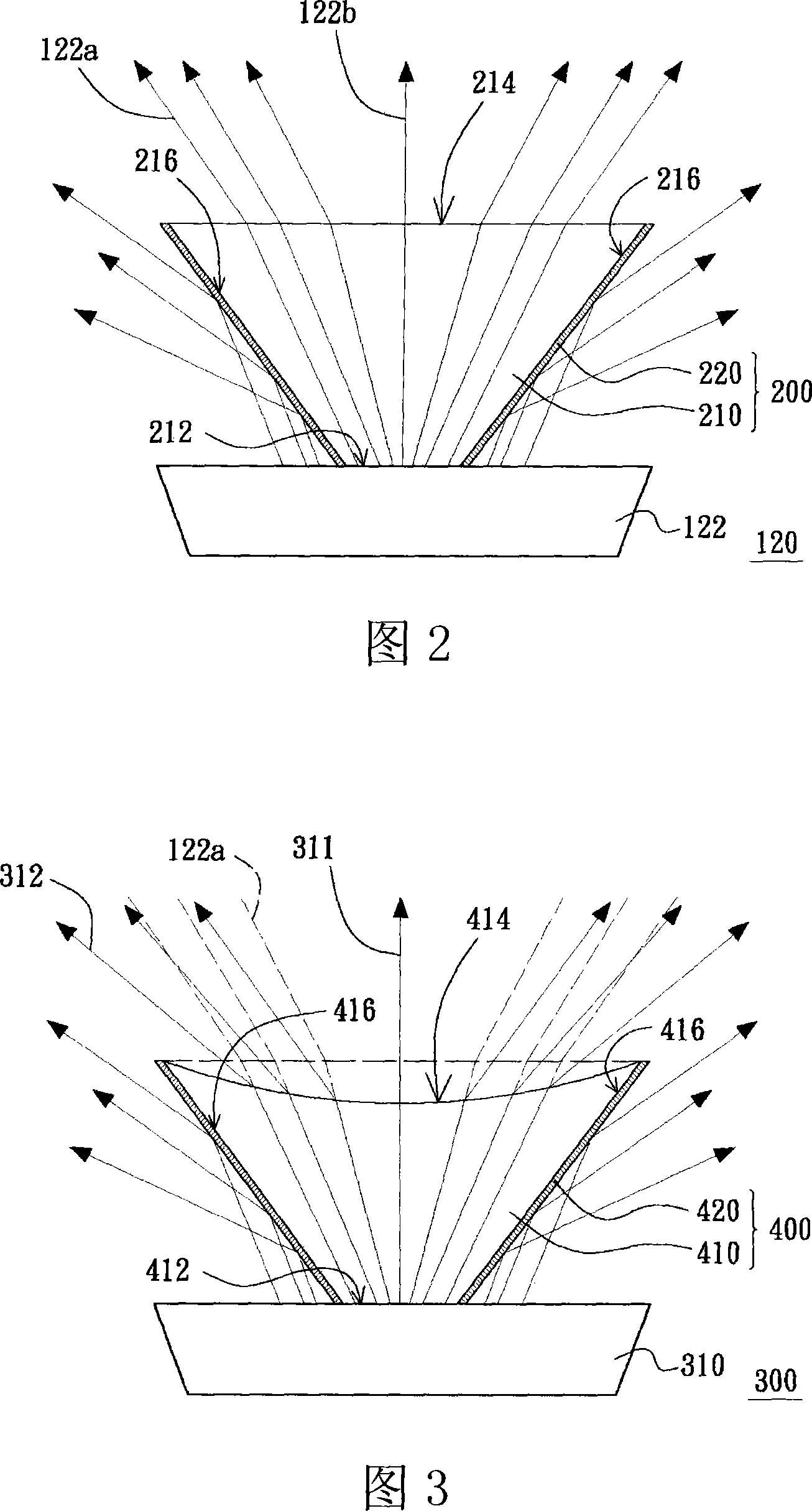

[0053] FIG. 3 is a schematic diagram of a light emitting unit according to an embodiment of the present invention. Referring to FIG. 3 , the light emitting unit 300 of this embodiment includes an LED light source module 310 and a lens structure 400 , wherein the lens structure 400 is disposed on the LED light source module 310 . The lens structure 400 includes a lens body 410 , and the lens body 410 has a light incident surface 412 , a light output surface 414 and a reflective surface 416 . The light incident surface 412 is opposite to the light exit surface 414 , and the reflective surface 416 is conical and connected between the light incident surface 412 and the light exit surface 414 . The area of the light incident surface 412 is smaller than that of the light exit surface 414 , and the light exit surface 414 is a concave curved surface.

[0054]In the aforementioned lens structure 400 , the light incident surface 412 is a plane, and the light incident surface 412 face...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius of curvature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com