Preparation method of perovskite quantum dot composite

A technology of perovskite and quantum dots, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as low efficiency and cumbersome methods, and achieve less operation steps and simple methods , optimize the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

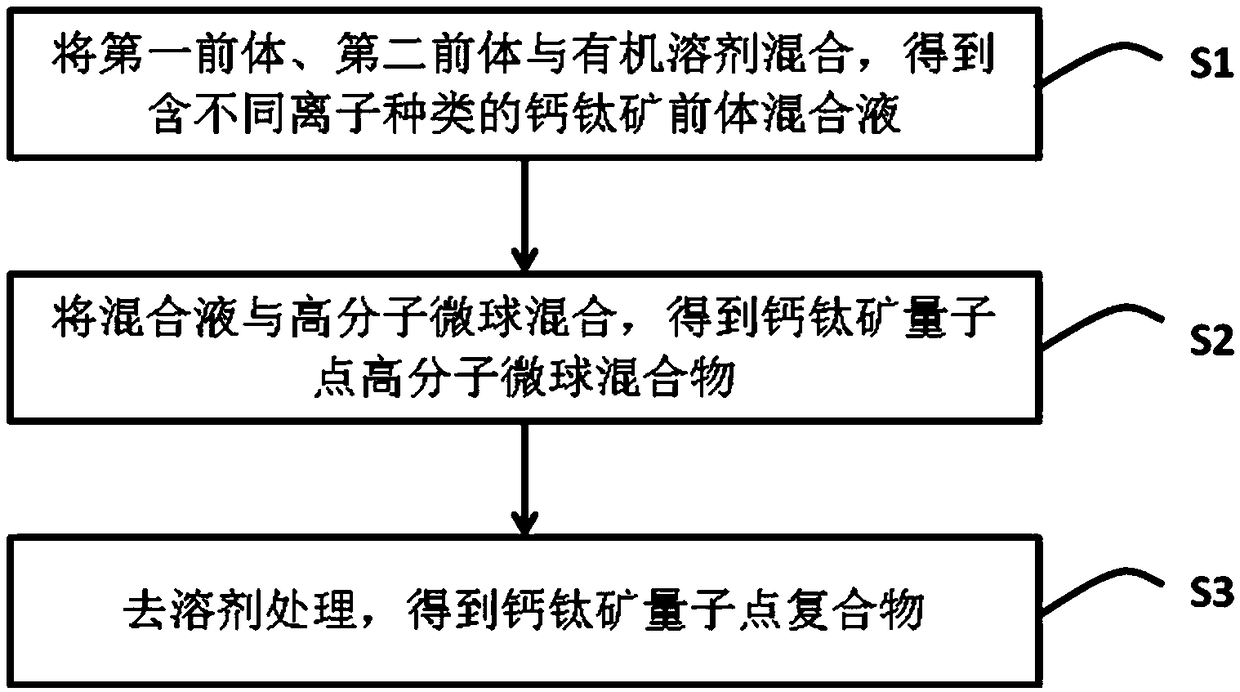

Method used

Image

Examples

Embodiment 1

[0031] Preparation of CH 3 NH 3 PbBr 3 Perovskite Quantum Dot Composite

[0032] S1, the CH 3 NH 3 Br, PbBr 2 mixed with N,N-dimethylformamide, where, CH 3 NH 3 Br and PbBr 2 The ratio of the amount of substance is 5:1, N,N-dimethylformamide and PbBr 2 The mass ratio is 50:1. Mix evenly and stir under the protection of argon to obtain a perovskite precursor mixed liquid.

[0033] S2. Add polystyrene microspheres with a particle size of 3 μm to the above perovskite precursor mixture, wherein the mass of polystyrene microspheres is the same as that of CH 3 NH 3 Br and PbBr 2 The total mass ratio is 4:1. Mix and stir evenly under the protection of argon to obtain the perovskite quantum dot polymer microsphere mixture.

[0034] S3. Centrifuge the above perovskite quantum dot polymer microsphere mixture, pour off the supernatant, take out the precipitate and pour it into a glass dish, put the glass dish on a baking board to heat, set the heating temperature to 60°C, a...

Embodiment 2

[0038] Preparation of CsPbBr 3 Perovskite Quantum Dot Composite

[0039] S1, the CsBr, PbBr 2 Mixed with dimethyl sulfoxide, among them, CsBr and PbBr 2 The ratio of the amount of substance is 2:1, DMSO to PbBr 2 The mass ratio is 100:1. Mix evenly and stir under the protection of argon to obtain a perovskite precursor mixed solution.

[0040] S2. Add polystyrene microspheres with a particle size of 15 μm to the above perovskite precursor mixture, wherein the mass of polystyrene microspheres is the same as that of CsBr and PbBr 2 The total mass ratio is 3:1. Mix and stir evenly under the protection of argon to obtain the perovskite quantum dot polymer microsphere mixture.

[0041] S3. Centrifuge the above perovskite quantum dot polymer microsphere mixture, pour off the supernatant, take out the precipitate and pour it into a glass dish, put the glass dish on a baking board to heat, set the heating temperature to 80°C, and the heating time 2h, to get CsPbBr 3 Perovskite...

Embodiment 3

[0045] Preparation of CH 3 NH 3 PbBr 3 Perovskite Quantum Dot Composite

[0046] S1, the CH 3 NH 3 Br, PbBr 2 mixed with N,N-dimethylformamide, where, CH 3 NH 3 Br and PbBr 2 The ratio of the amount of substance is 6:1, N,N-dimethylformamide and PbBr 2 The mass ratio is 200:1. Mix evenly and stir under the protection of argon to obtain a perovskite precursor mixed liquid.

[0047] S2. Add polymethyl methacrylate microspheres with a particle size of 5 μm to the above perovskite precursor mixture, wherein the mass of polymethyl methacrylate microspheres is the same as that of CH 3 NH 3 Br and PbBr 2 The total mass ratio is 3:1. Mix and stir evenly under the protection of argon to obtain the perovskite quantum dot polymer microsphere mixture.

[0048] S3. Centrifuge the above perovskite quantum dot polymer microsphere mixture, pour off the supernatant, take out the precipitate and pour it into a glass dish, put the glass dish on a baking board to heat, set the heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com