Three-dimensional scanners and its three-dimensional model reconfiguration method

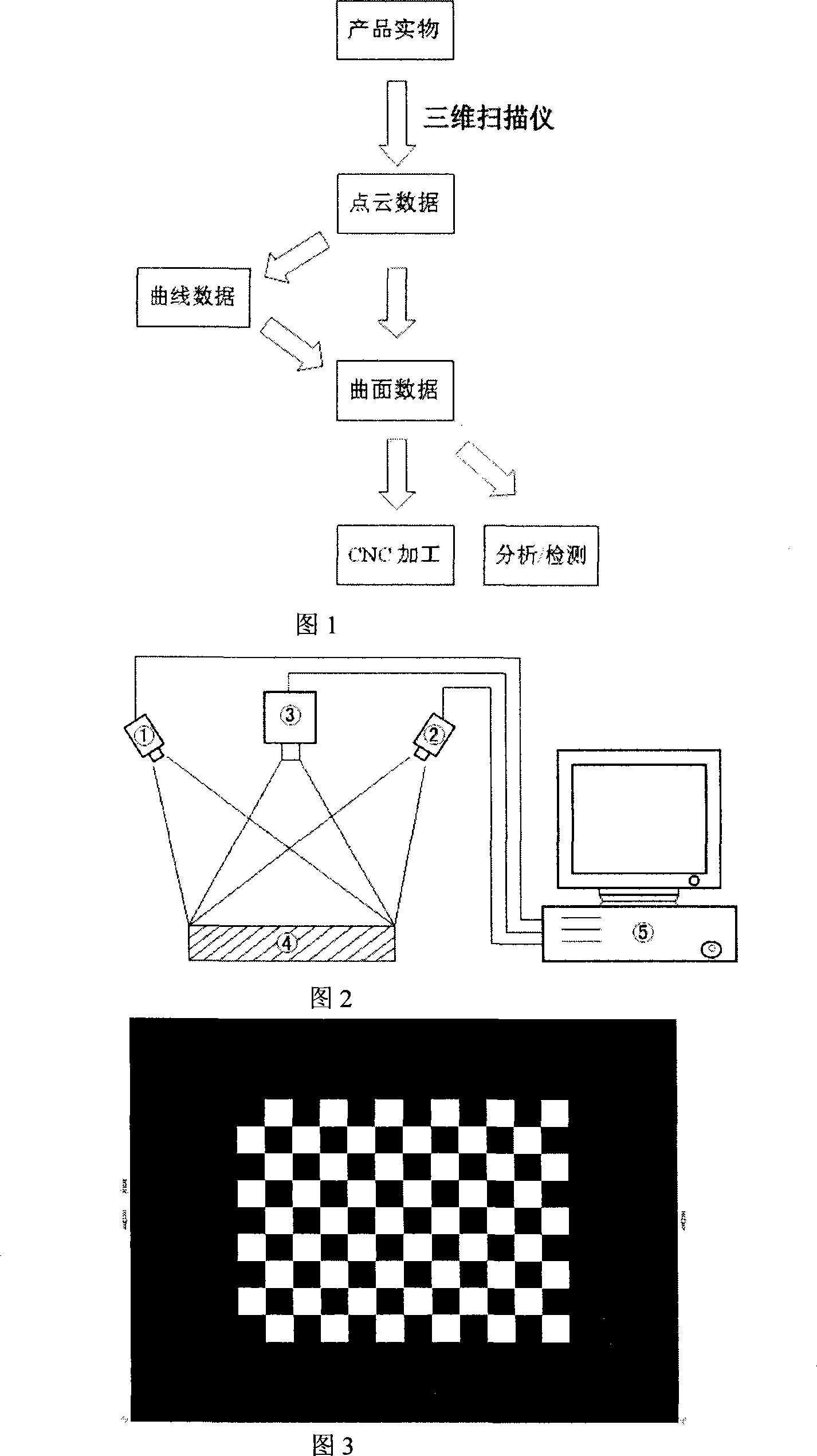

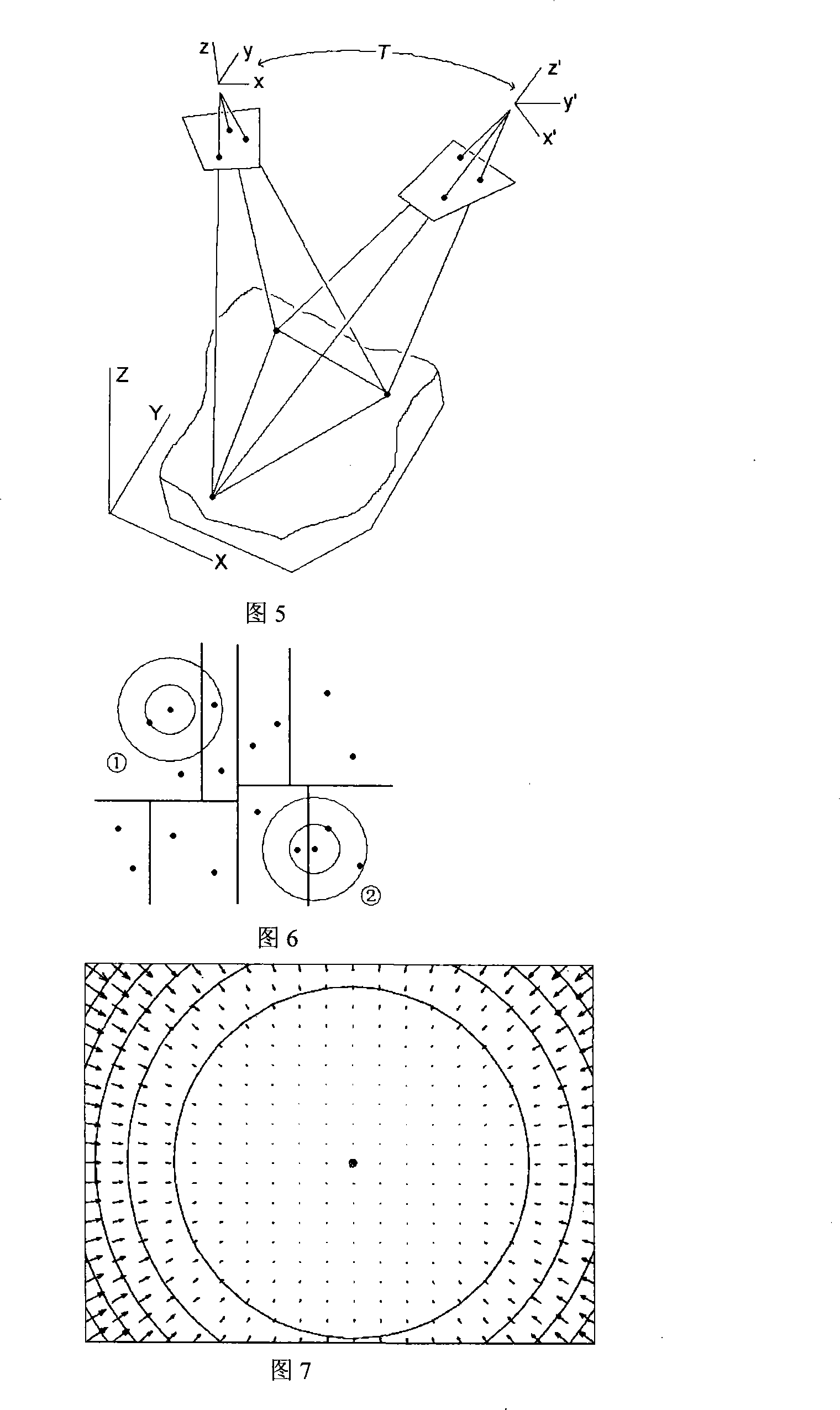

A scanner and three-dimensional technology, applied in the field of three-dimensional scanning, can solve the problems of slow scanning speed, complicated operation, and inapplicability in the application field of three-dimensional scanning technology, so as to achieve strong applicability and improve the effect of stitching speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] 1. Raster type 3D scanner

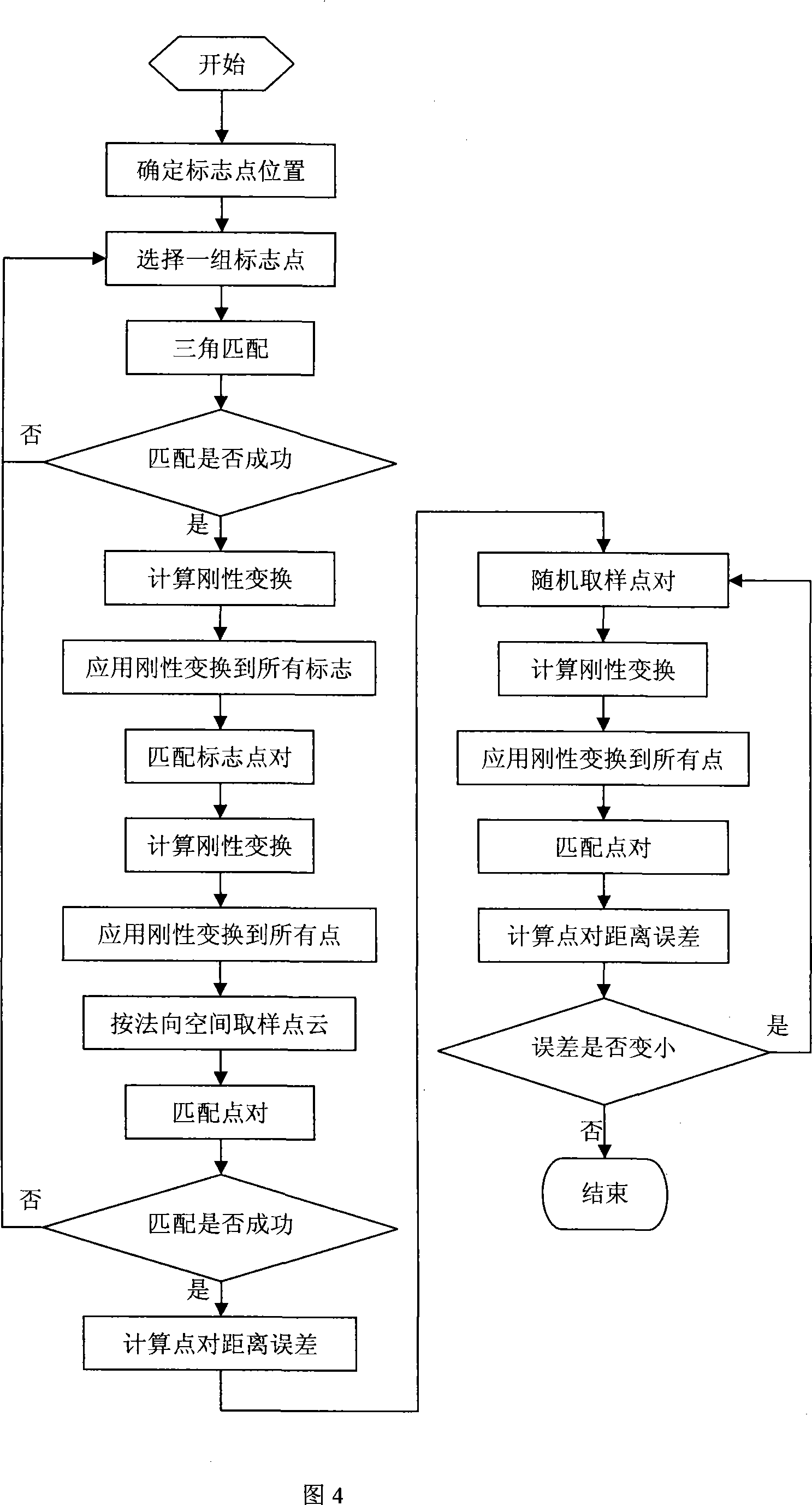

[0032] The system structure adopted in the present invention (as shown in Figure 2) is composed of grating generating equipment ③, image acquisition equipment ①②, calibration block ④, computer communication board ⑤ and peripheral mechanical support facilities. The grating generating device ③ is connected with the computer communication board ⑤, which is a light source device that can generate grating structured light, and its grating pattern can be changed by computer control. The image acquisition device ①② is connected with the computer communication board ⑤. Its main function is to collect the reflected image of the projected grating from the tested part. The number can be only one, or two to eight. The specific number depends on the system accuracy requirements. And it depends on the size of the object to be measured. Calibration block ④ (as shown in Figure 3) is a standard gauge block with strictly controlled dimensions and printed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com