Method and building system for manufacture a floating structure

A floating structure and support structure technology, applied in transportation and packaging, ships, prefabricated cabins, etc., can solve the problems of increasing the number of cabins and passenger capacity, increasing the number of decks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

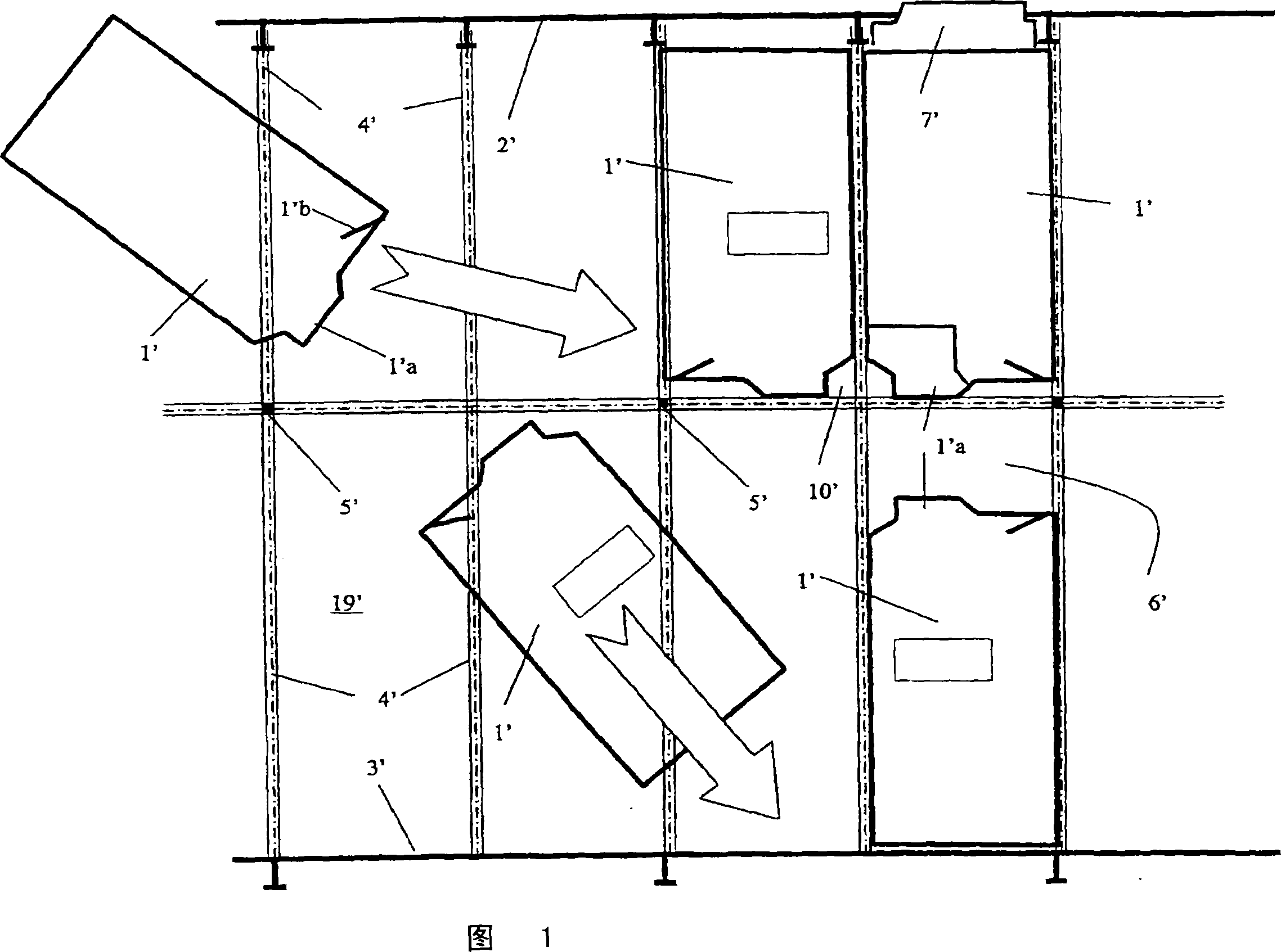

[0020] Traditionally, moving and installing a cabin unit to a ship or the like is carried out in the manner shown in FIG. 1 . Therefore, a prefabricated self-supporting cabin unit 1' with toilet (WC) unit 1'a and entrance door 1'b is placed one by one on the outer structure 2', inner support structure 3' and deck beam 4' of the vessel as indicated by the arrows between the vertical struts 5', thereby placing them in place on the deck 19' of the vessel. Conventionally, only every other deck beam 4' is supported by struts 5' in order to facilitate the installation of the cabin unit 1'. As is known per se, there can be several decks on a ship, which are supported by said parts 2', 3', 4' and 5', in addition deck girders along the longitudinal direction of the ship are used, as shown in Fig. As shown, they are placed transversely to the deck beam 4'. The rest of the vessel structure is not shown in detail as it is not too relevant for the present application.

[0021] The cabin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com