Oven with premix burner for boiler

A burner, gas burner technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of low production standardization and rising production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

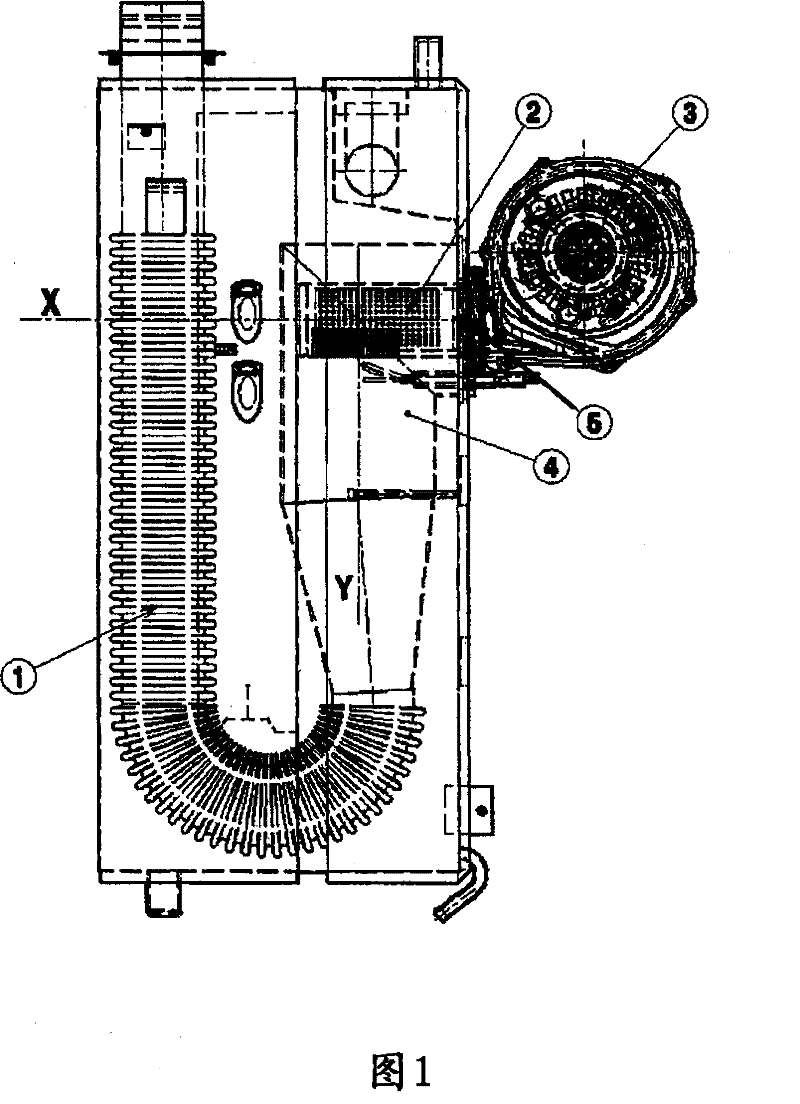

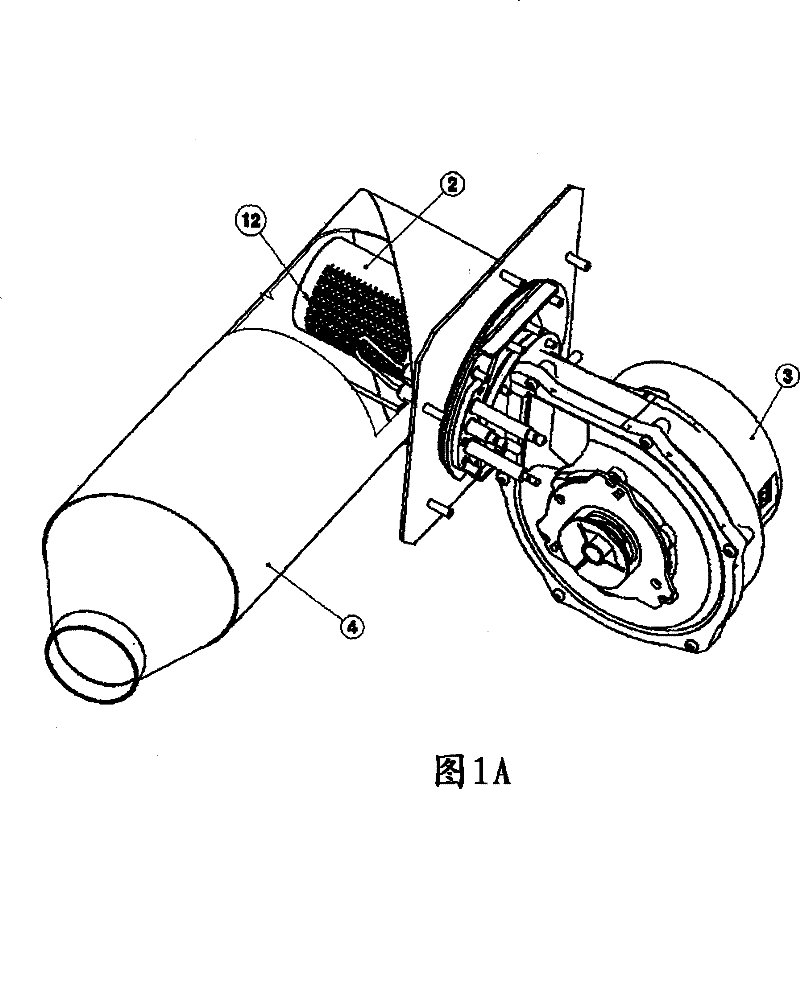

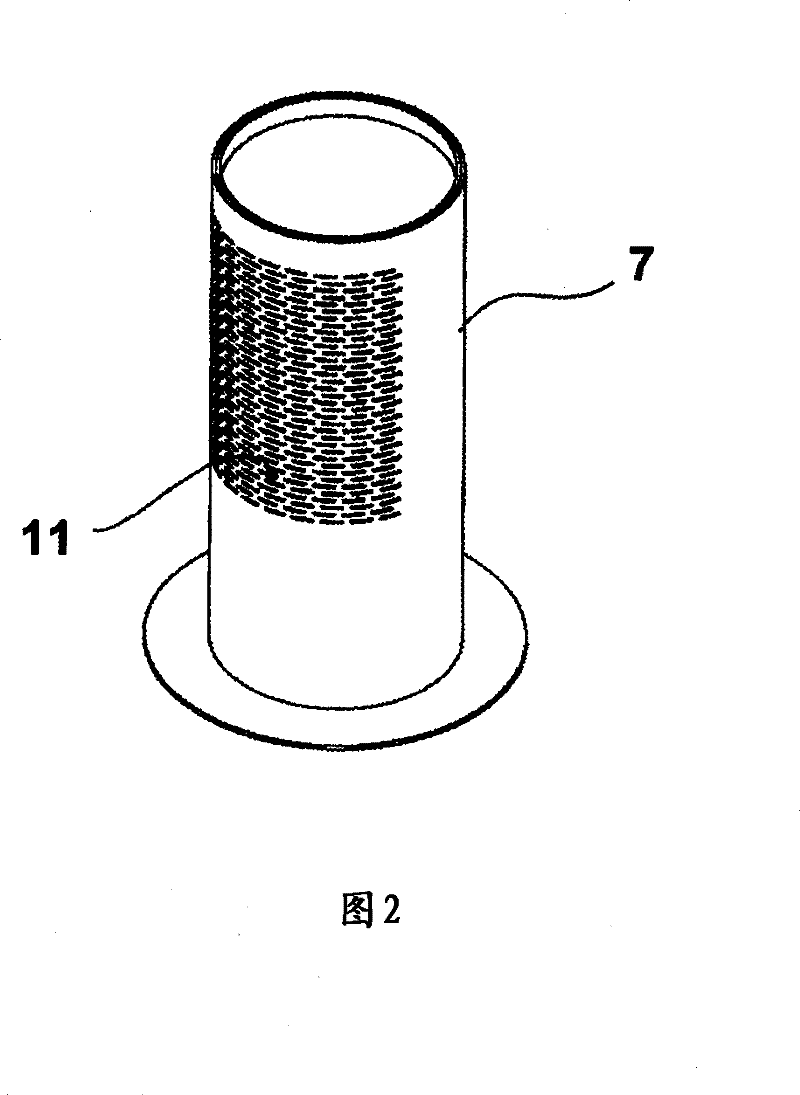

[0016] The present invention is primarily based on the following considerations: as its main purpose is to provide a gas burner which can potentially be adapted to ensure a heat output which can vary over a considerable range, and where such a wide range of heat output should be possible by means of corresponding Since regulation is performed by controlling variables rather than burner size, the solution sought, and thus found, is to define some features of the burner which effectively increase the efficiency of the burner while preferably reducing the space requirement, i.e. increasing the burner of compactness.

[0017] However, in order to achieve the above goals, it is necessary to avoid direct combustion of the gas at the outlet of the gas nozzle, and at the same time set an intermediate premixing zone between the flame zone and the nozzle outlet.

[0018] It has been found that by providing such a premixing zone upstream of the flame zone, ie before the flame zone, an op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com