Independent intelligent control type automobile frame

A car frame, independent and intelligent technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems of safety hazards, affecting comfort, limited shock absorption effect, etc., to achieve good shock absorption performance, stable performance, The effect of preventing rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

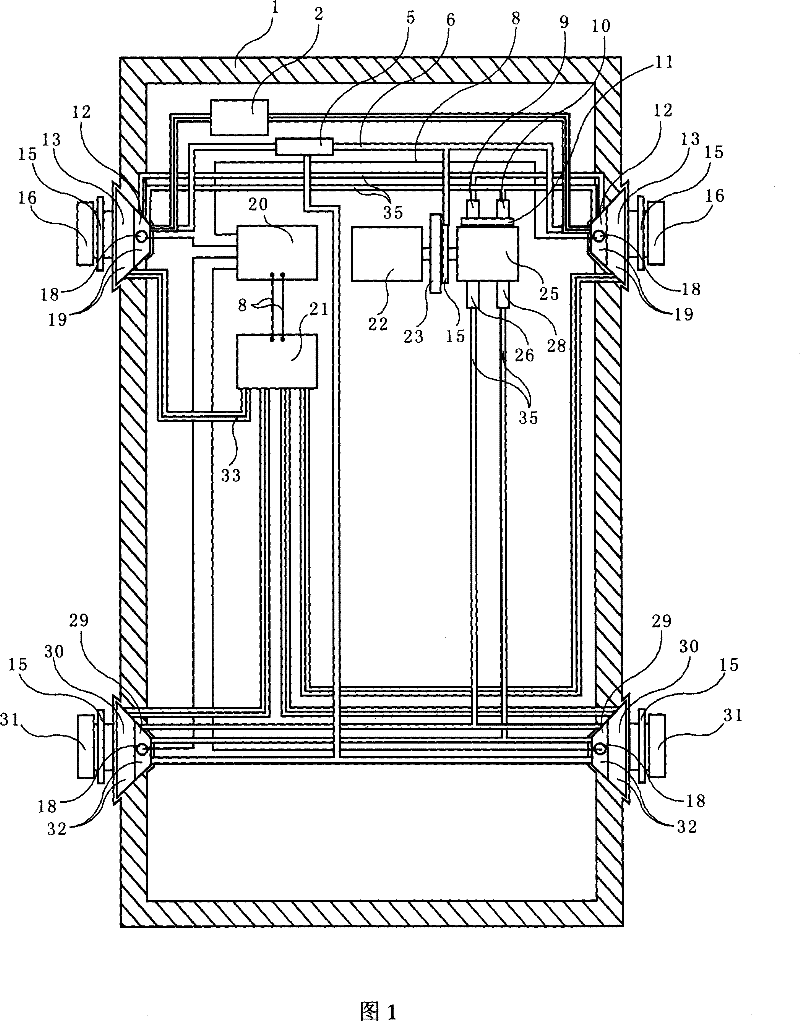

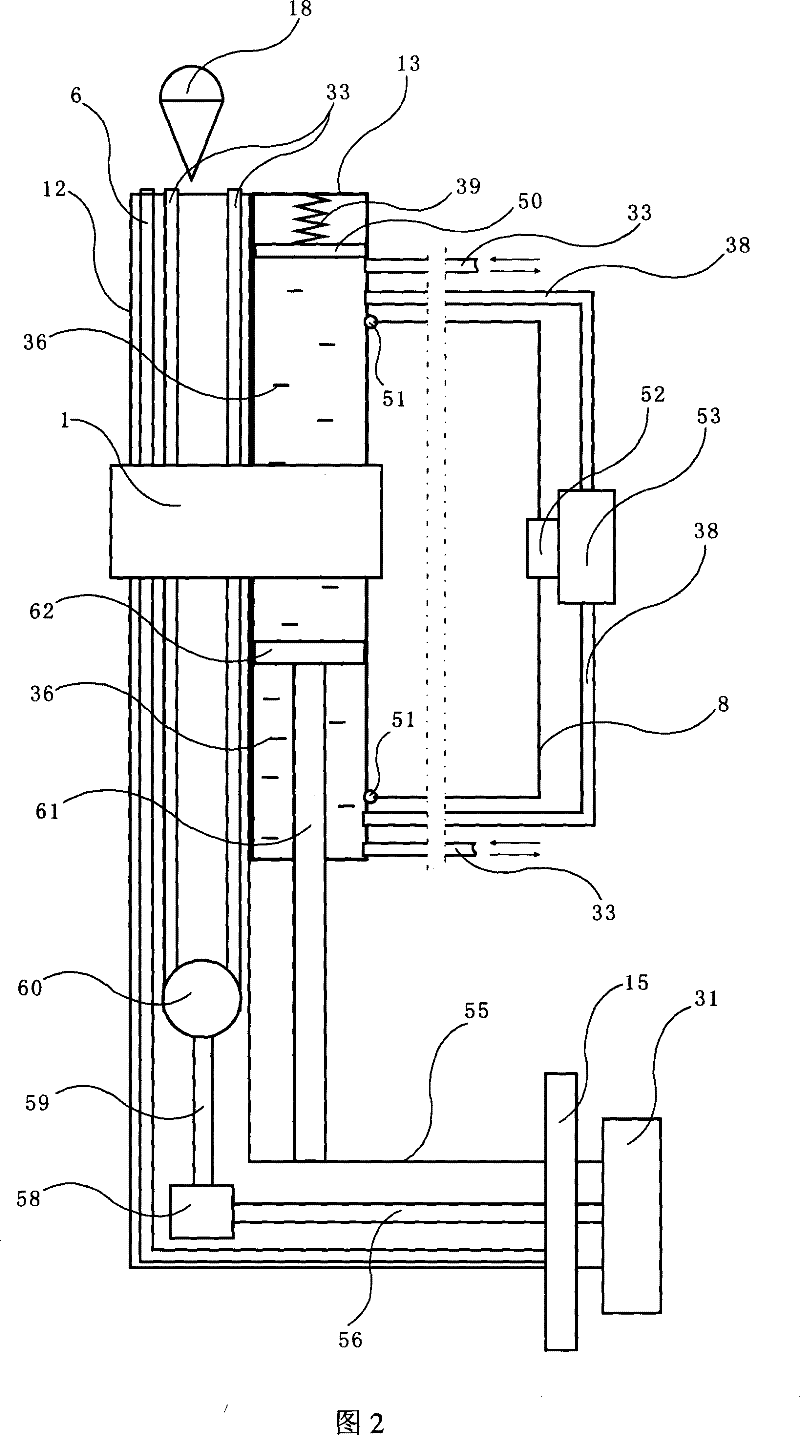

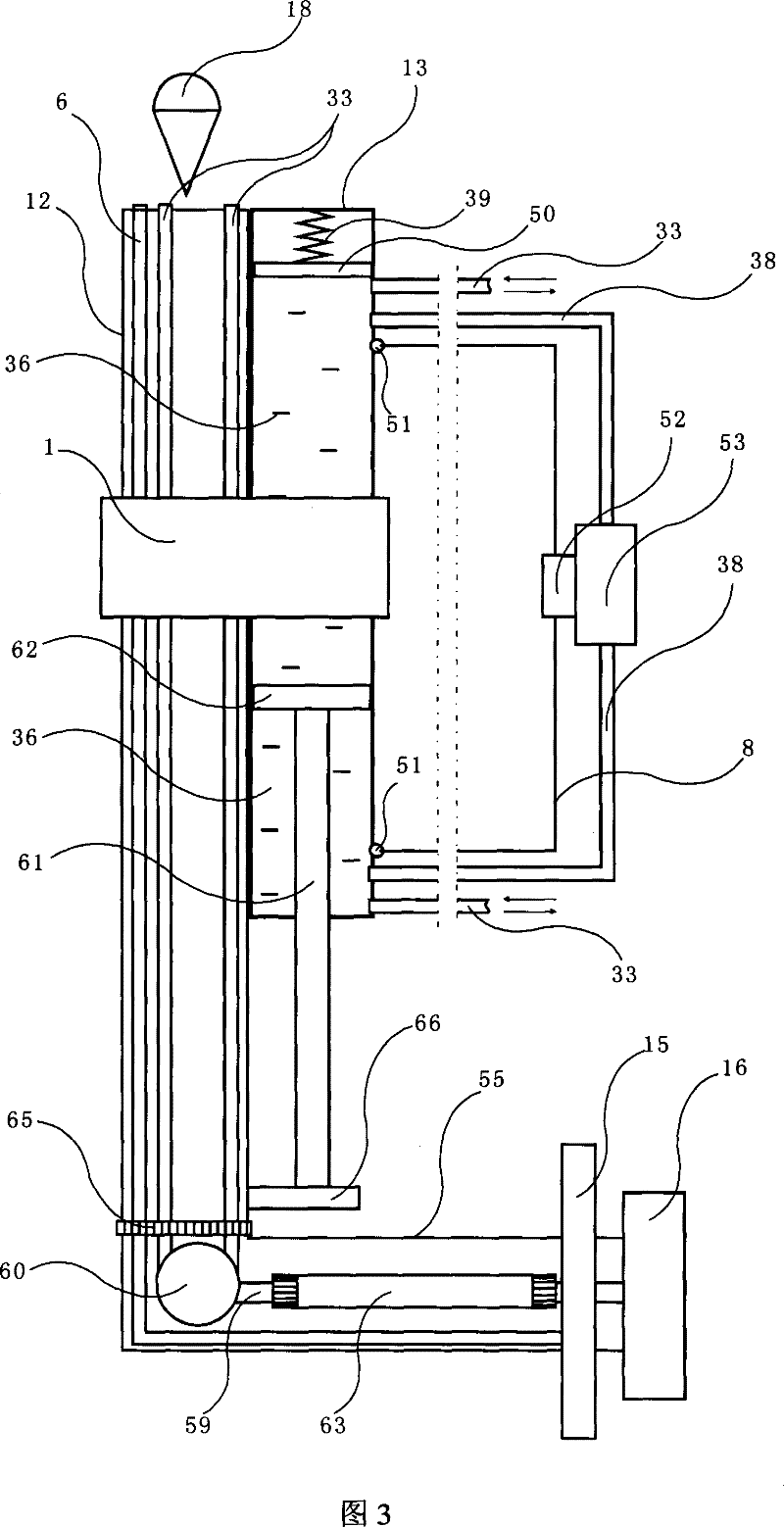

[0023] Such as figure 1 As shown, the present invention is loaded by the wheel, including the load-bearing column between the vehicle frame girder 1 and the wheel, and also includes all electronic control devices, power transmission devices, shock-absorbing balance devices, Steering device and braking device; there is no mechanical hard connection device other than the beam 1 between the load-bearing columns between the frame girder 1 and each wheel; combined figure 1 , figure 2 and image 3, the load-bearing column is formed by connecting a hollow load-bearing horizontal column 55 and a load-bearing column end to end, and the outer end of the load-bearing horizontal column 55 is connected with the wheel device, and the load-bearing column includes vertical and parallel stabilizing piles 12 and a hydraulic column; 13. The load-bearing vertical rod 61 is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com