Rotary hearth furnace and screw rod for discharging reduced iron

A technology for reducing iron and rotary hearth furnaces, applied in furnaces, furnace components, manufacturing converters, etc., and can solve problems such as a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

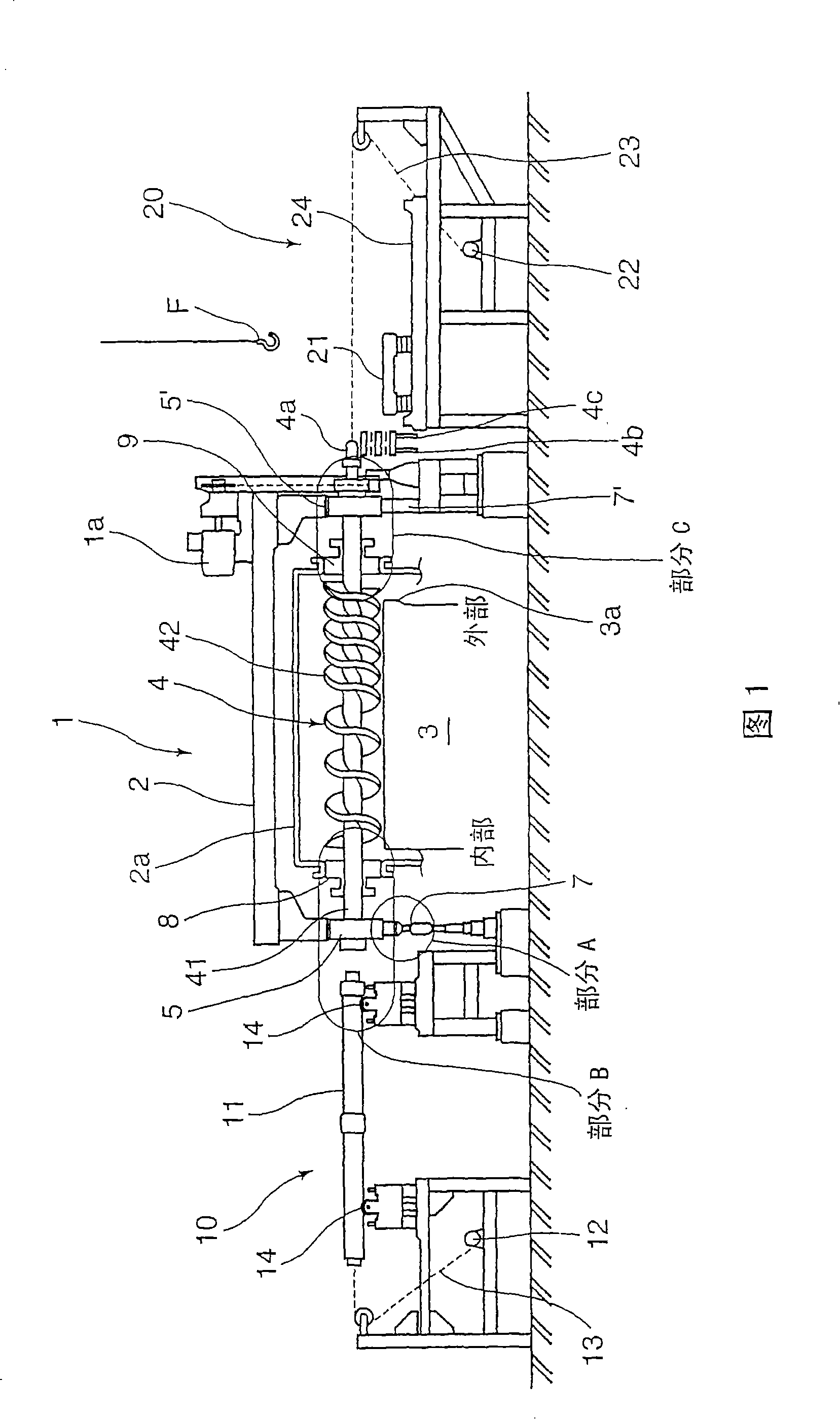

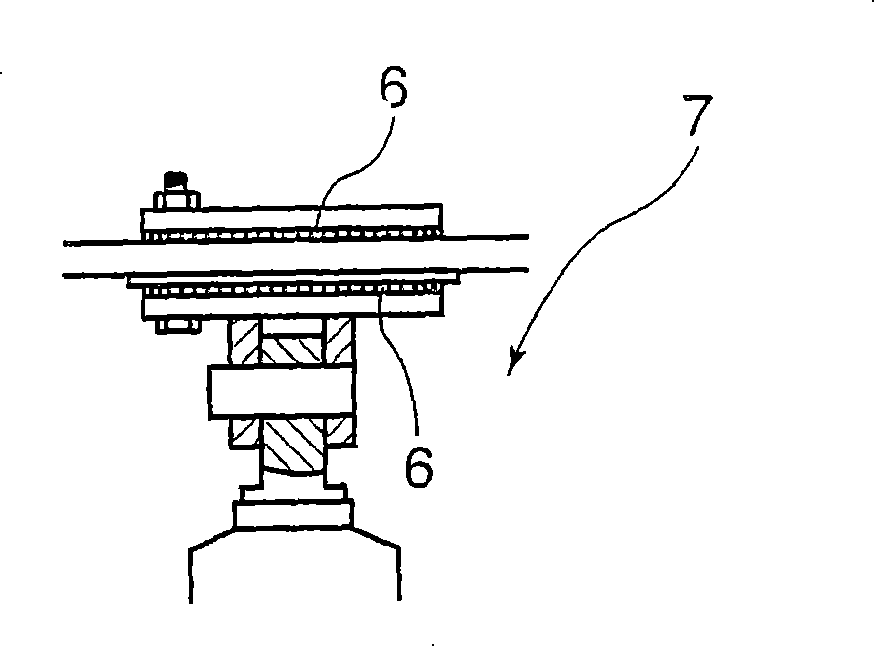

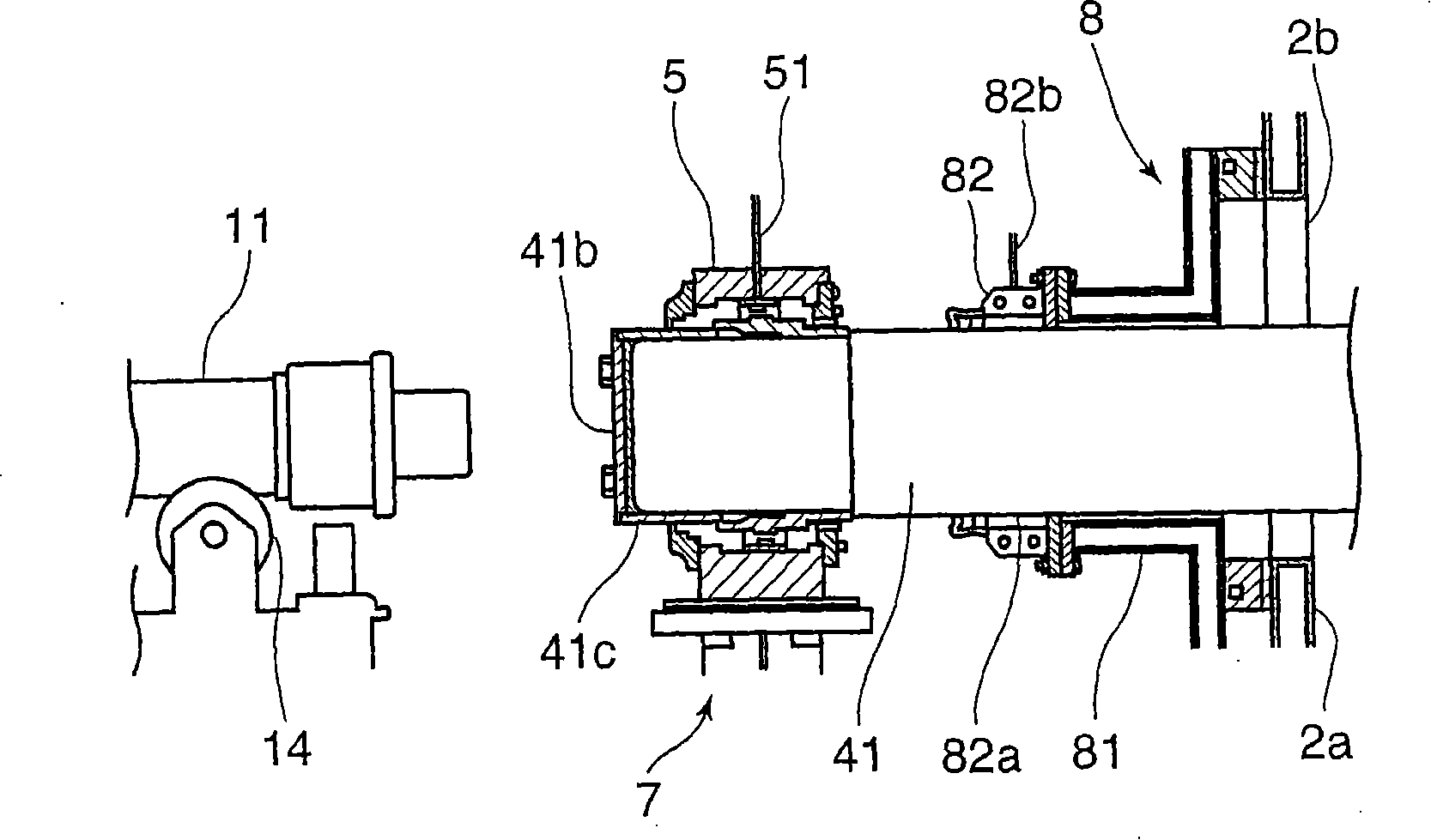

[0024] Hereafter, the rotary hearth furnace and the reduced iron discharge screw of the rotary hearth furnace according to a preferred embodiment of the present invention will be described in conjunction with the accompanying drawings, wherein: Fig. 1 illustrates the cross-sectional composition of the arrangement position of the reduced iron discharge screw of the rotary hearth furnace; figure 2 is a detailed view of part A of FIG. 1; image 3 is a detailed view of part B of FIG. 1; Figure 4 is a detailed view of part C of FIG. 1; Figure 5 is a sectional view of the axis of rotation of the reduced iron discharge screw; Image 6 is a cross-sectional view of the helical blade; and Figure 7 The side configuration of the reduced iron discharge screw is illustrated.

[0025] Reference numeral 1 shown in FIG. 1 denotes a rotary hearth furnace comprising a furnace body 2 having a reduced iron discharge screw 4 constructed as follows for directing the The reduced iron on the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com