Method for reducing iron mineral powder during transferring process

A technology for iron ore powder and ore powder, which is applied in the field of heating and reduction in the process of ore powder conveying, can solve problems such as powder ore sticking, and achieve the effects of reducing energy consumption and emission and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

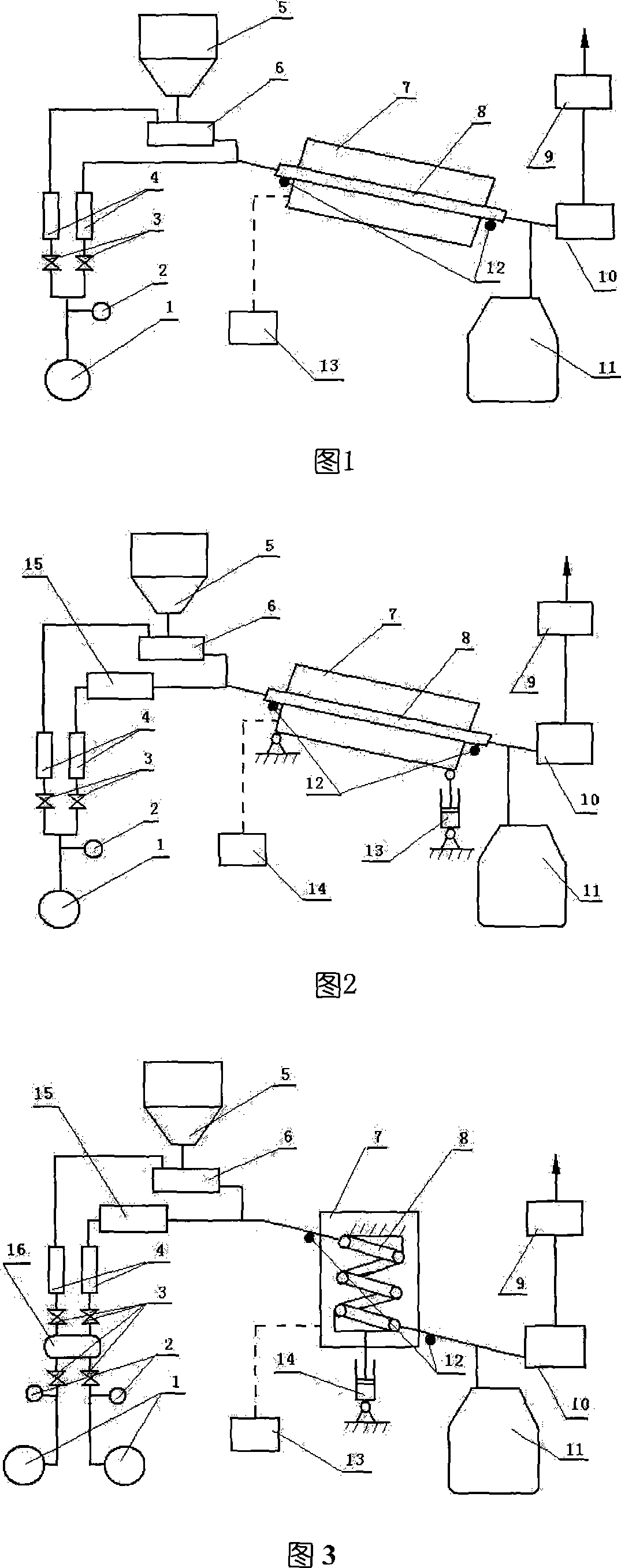

[0011] In Figure 1, the reducing gas with a certain temperature and pressure comes out of the gas source (1) and is divided into two paths, the flow is controlled by the valve (2) and the flow meter (3) respectively, and one path enters the connecting silo as a carrier gas The feeder (6) of (5), another road directly enters the final reduction furnace (11) or Enter the cooling collector (10) for storage. A vibrator (12) is installed at both ends of the tubular reactor, the reaction temperature is adjusted by a temperature controller (13), and the exhaust gas from the collector is treated by a dust removal and purification device (9) before being discharged.

[0012] In the first embodiment shown in Fig. 2, the angle between the tubular reactor (8) and the horizontal line can be adjusted by an inclination regulator (14), and the reducing gas can be preheated by a preheater (15).

[0013] In the second embodiment shown in the figure, different reducing gases (1) can be mixed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com