Cigarette flue gas aerosol grain size distribution detection method

A particle size distribution and cigarette smoke technology, which is applied in the detection of aerosol particle distribution of different particle sizes in cigarette smoke, and the detection field of cigarette smoke aerosol particle size distribution, can solve the problem of detection results exceeding, pipeline blockage, and satisfying No problems such as requirements, to achieve the effect of significant effect and prevent backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

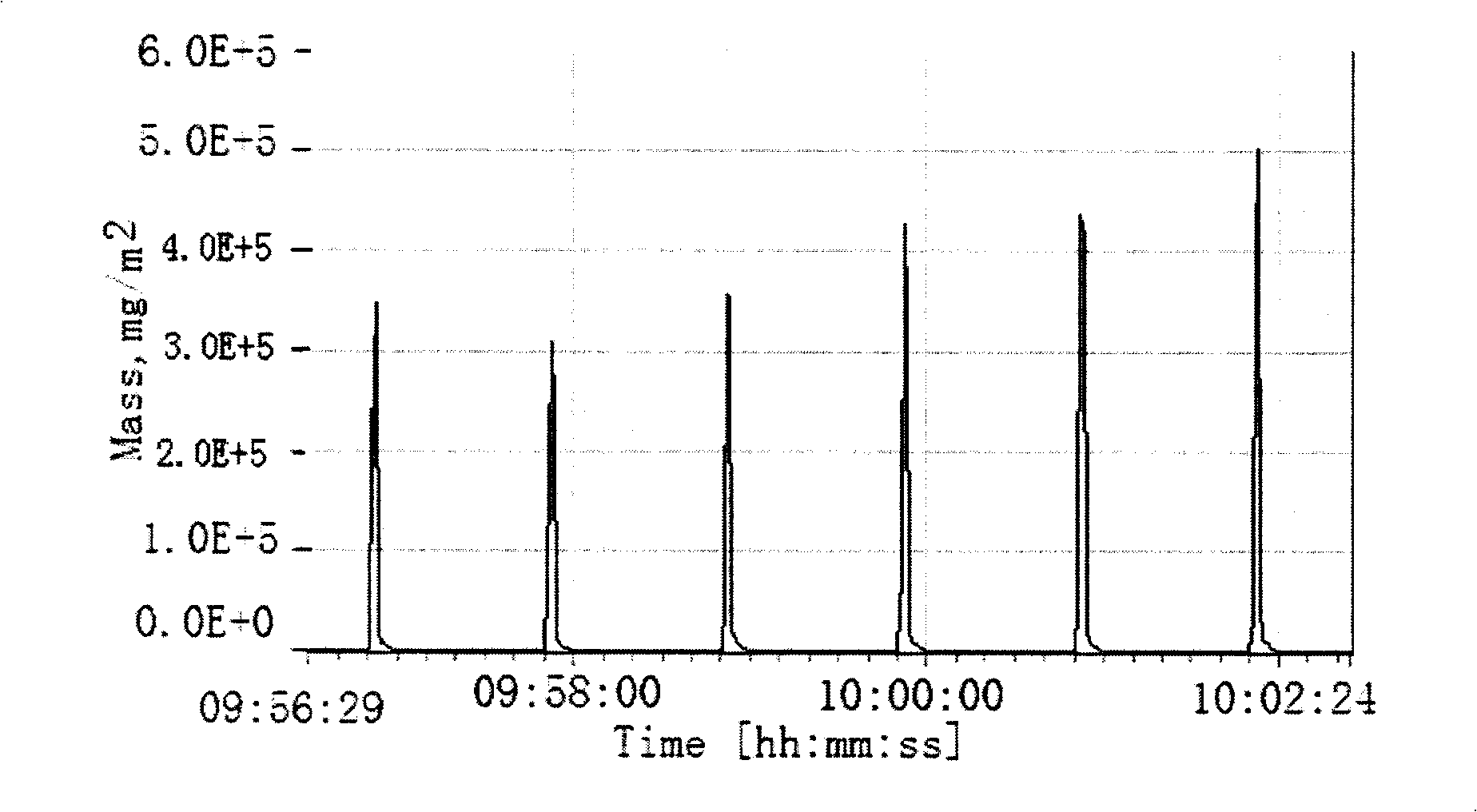

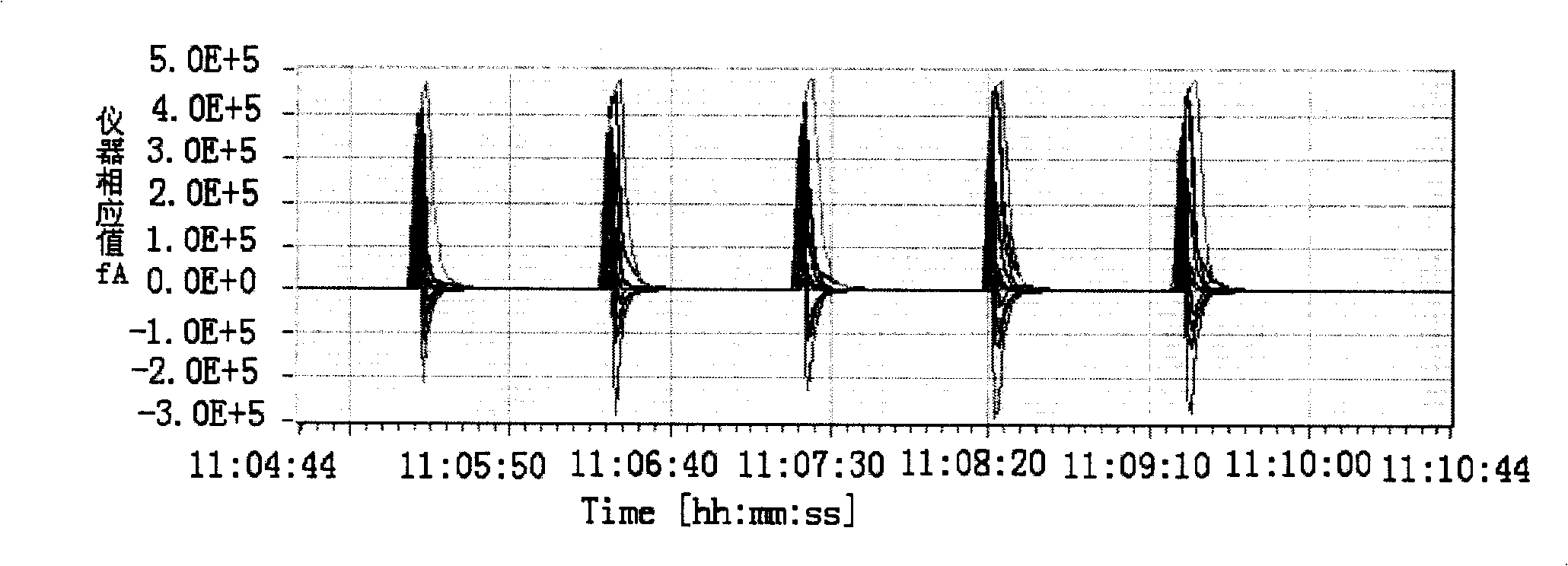

[0040] Cigarette smoke generating device Smoking machine and electromagnetic valve suck cigarettes to generate smoke. The existing aerosol detector is used to directly measure the aerosol content of cigarette smoke flowing out of the smoking machine. The suction source device of the detector itself usually requires The stable flow rate of the measured sample airflow is 10L / min~40L / min, but because the aerosol concentration in the flue gas is much higher than that in the air, the detector is seriously overloaded. The detection result exceeds the detection limit of the instrument (4.0×10 5 fA), there was no difference between the detected values, and all reached the maximum value, etc., the results are as attached figure 1 As shown, the detection analysis cannot be performed.

[0041] If the axial diluter provided by the manufacturer of the aerosol detector is used to dilute the cigarette smoke and then carry out aerosol detection, the pipeline is still often blocked, the press...

Embodiment 2

[0043] (1) The cigarette sample passes through the smoke generating device to generate a smoke sample stream 1;

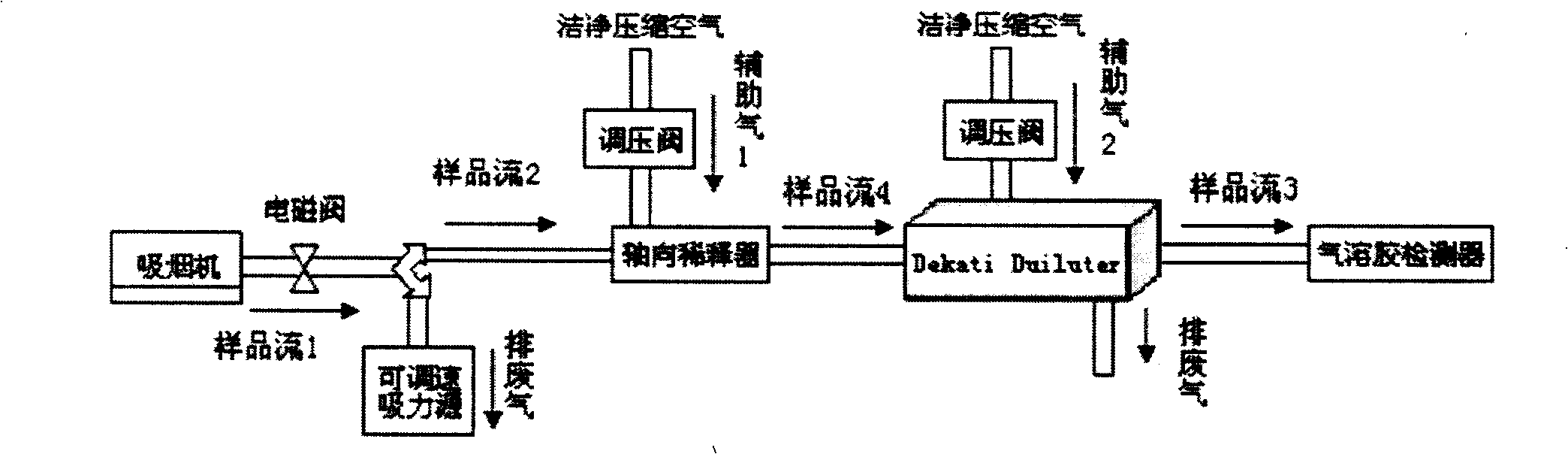

[0044] as attached image 3 As shown, the smoke generating device includes a smoking machine and a solenoid valve. The smoking machine can be used to suck cigarettes to generate cigarette smoke. The cigarette smoke (sample flow 1) simulates the smoking process through the solenoid valve. It is set according to the cigarette detection requirements, usually Open for 2s, close for 58s, repeat until the cigarette is smoked.

[0045] (2) Use an external suction source to adjust the gas flow rate of sample flow 1 to 1mL / min~1.8mL / min;

[0046] as attached image 3 As shown, the flue gas (sample flow 1) flowing out from the flue gas generating device flows into a three-way valve, and the two outlets of the three-way valve are respectively connected to the flue gas sample detection pipe (sample flow 2 flows through the pipe) and the flowmeter, the flowmeter Then it is c...

Embodiment 3

[0056] Step (1) is with embodiment 2;

[0057] (2) Use an external suction source to adjust the gas flow rate of sample flow 1 to 1mL / min~1.8mL / min;

[0058] as attached Figure 5 As shown, the flue gas (sample flow 1) flowing out from the flue gas generating device flows into a three-way valve, and the two outlets of the three-way valve are respectively connected to the flue gas sample detection pipe (sample flow 2 flows through the pipe) and the pressure regulating valve. The pressure valve is connected to the suction source, and the working efficiency of the suction source is required to be 1mL / min to 2mL / min, so as to ensure that the gas flow of sample flow 1 is adjusted to be 1mL / min to 1.8mL / min.

[0059] (3) Adjust the gas flow rate of the sample flow 3 entering the aerosol detector to be 10L / min~40L / min, and dilute it;

[0060] The gas flow rate of the sample stream 1 is adjusted to a range of 10L / min to 40L / min by means of auxiliary gas dilution. The clean compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com