Separator for direct methanol fuel cell

A methanol fuel cell and separator technology, applied in the separator field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

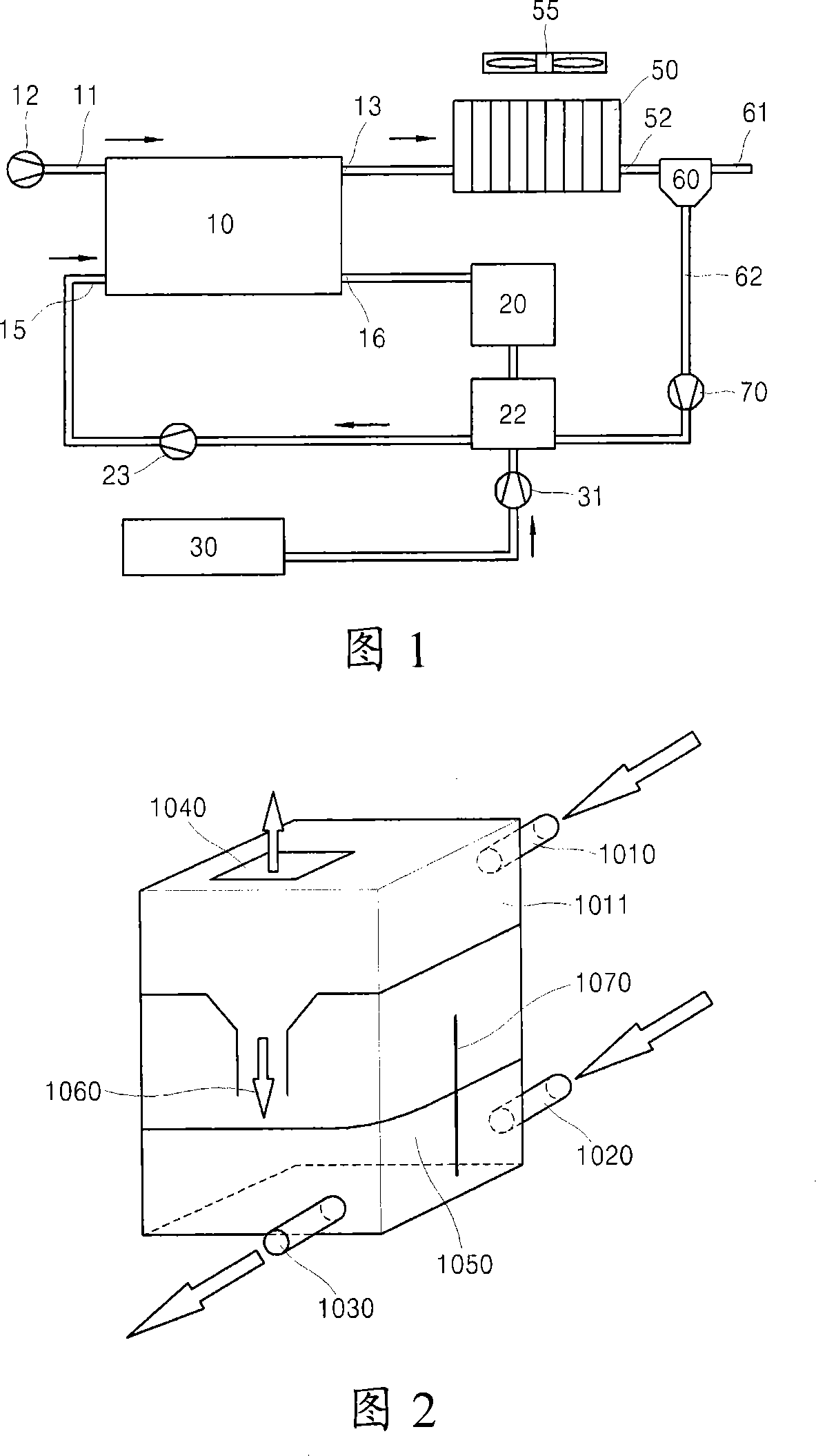

[0039] FIG. 1 illustrates the structure of a direct methanol fuel cell (DMFC). Electrochemical processes (which are not the object of the present invention and therefore need not be described in more detail) take place in the fuel cell stack 10 . The reaction product on the anode side contains CO 2 Liquid / gas mixture with water.

[0040] Air is supplied to the fuel cell stack 10 by means of a pump 12 through an inlet 11 on the cathode side. The supplied air can be discharged from the cathode side outlet 13 of the fuel cell stack 10 and cooled by the fan 55 and the heat exchanger 50 . Cooled air and condensed liquid thus exit heat exchanger 50 through outlet 52 to be provided to air separator 60 . The air separator 60 is connected via a corresponding line to the outlet valve 61 and to the mixer 22 via a line ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com