Nano-photocatalysis air purge clarification system

An air cleaning and purification system technology, applied in irradiation, deodorization, disinfection, etc., to ensure recycling and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

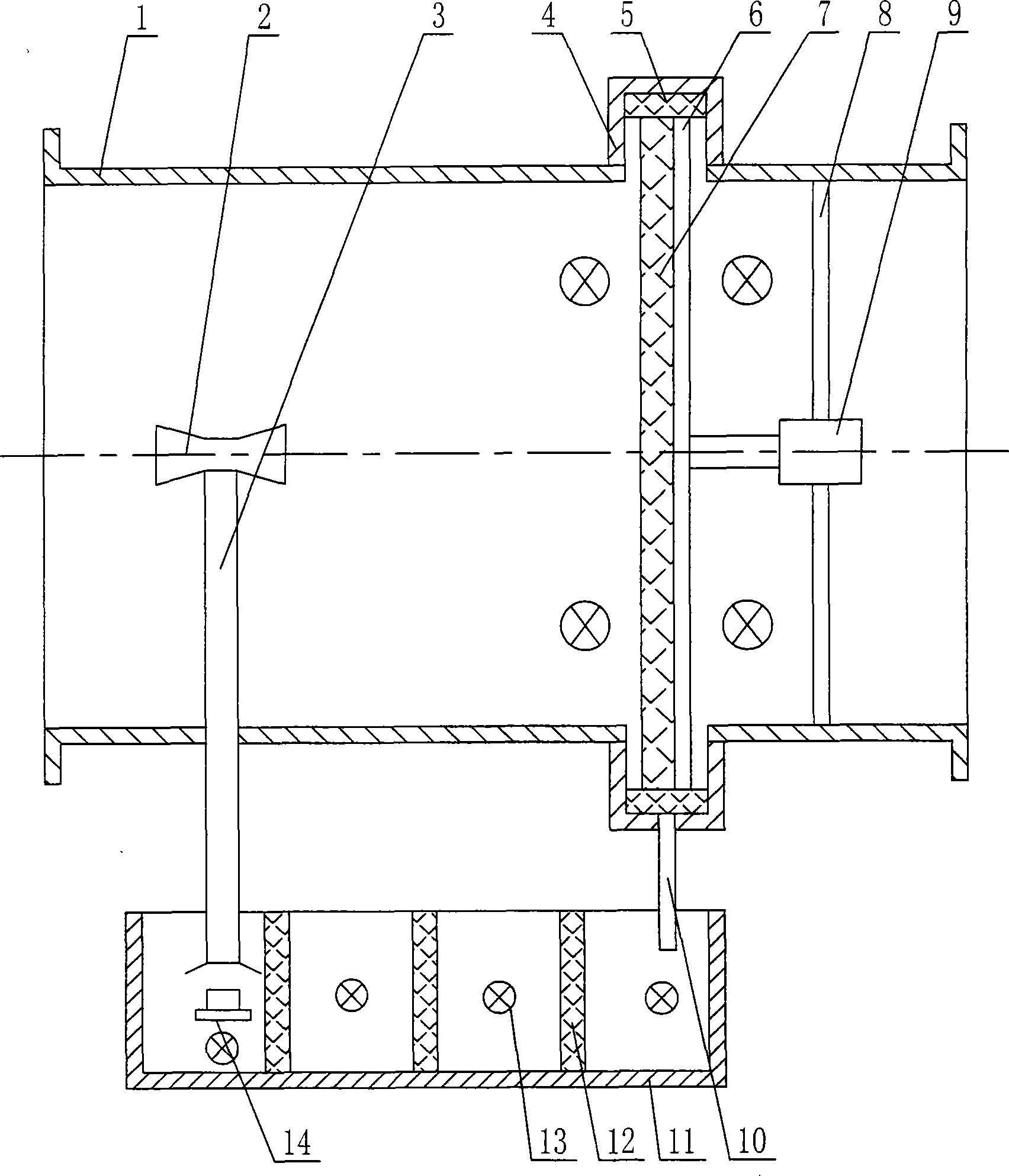

[0015] exist figure 1 Among them, the nanophotocatalytic air cleaning and purification system of this embodiment consists of a housing 1, a water mist nozzle 2, a mist guide 3, a collecting tank 4, a water absorption belt 5, a turntable skeleton 6, a demisting photocatalytic three-dimensional net 7, The motor bracket 8, the motor 9, the water outlet pipe 10, the return water storage and purification tank 11, the photocatalytic plate 12, the ultraviolet lamp 13, and the self-floating ultrasonic atomizer 14 are connected to form.

[0016] The downstream side of the airflow direction in the housing 1 is connected with the housing 1 to form a collecting tank 4 , the collecting tank 4 communicates with the housing 1 , and a water-absorbing belt 5 is installed in the collecting tank 4 . A return water storage purification tank 11 is placed below the outer surface of the housing 1, and the bottom of the collecting tank 4 is threadedly connected with an outlet pipe 10, and the lower e...

Embodiment 2

[0018] In this embodiment, the dehazing photocatalytic three-dimensional net 7 is loaded with nano-TiO 2 The photocatalyst is made of foamed stainless steel, and the demisting photocatalytic three-dimensional net 7 is disc-shaped with a thickness of 8mm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0020] In this embodiment, the dehazing photocatalytic three-dimensional net 7 is loaded with nano-TiO 2 The photocatalyst is made of foamed stainless steel, and the demisting photocatalytic three-dimensional net 7 is disc-shaped with a thickness of 20mm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com