Aeration machine impeller

An aerator and impeller technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as failing to achieve better aeration effect and weak oxygenation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

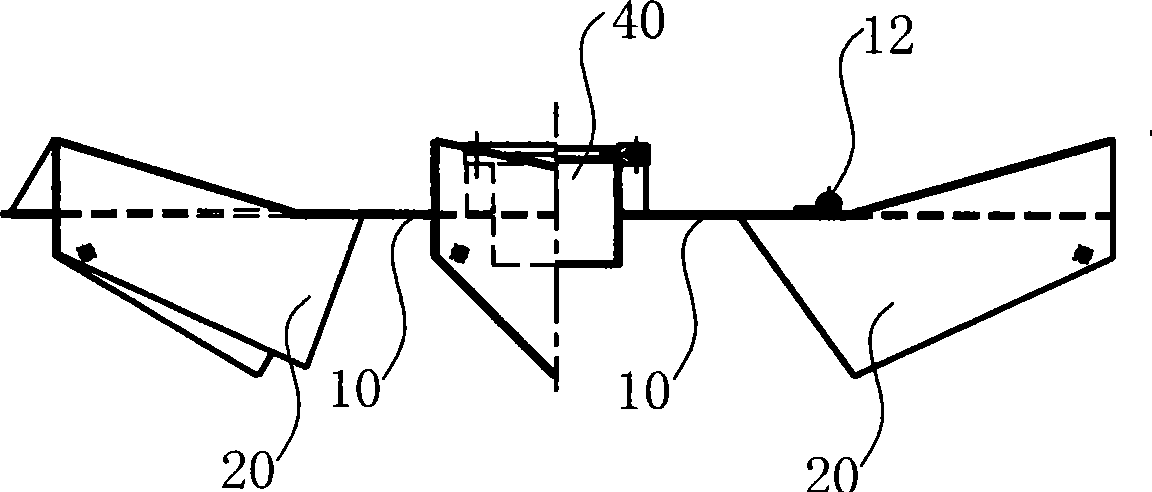

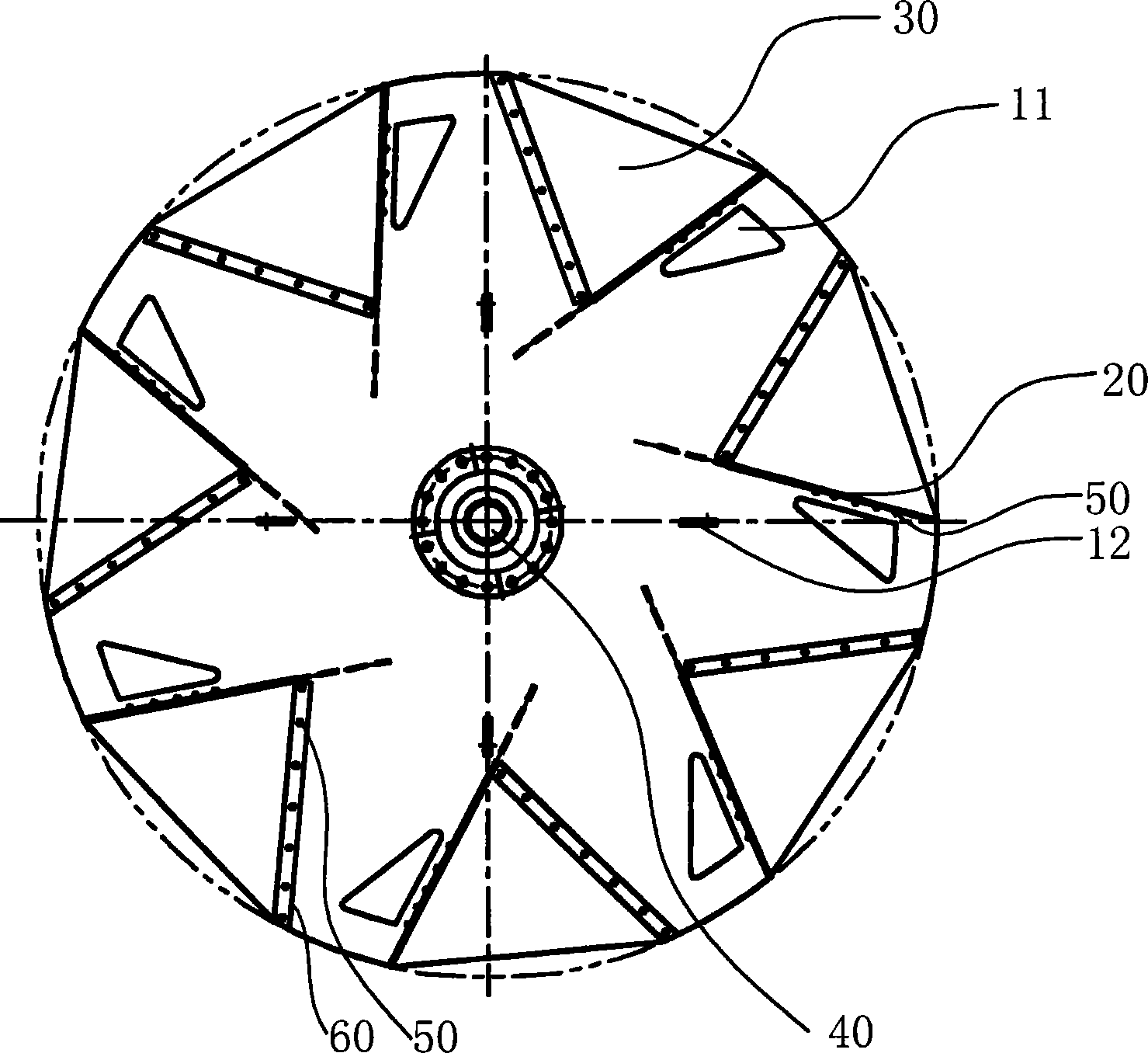

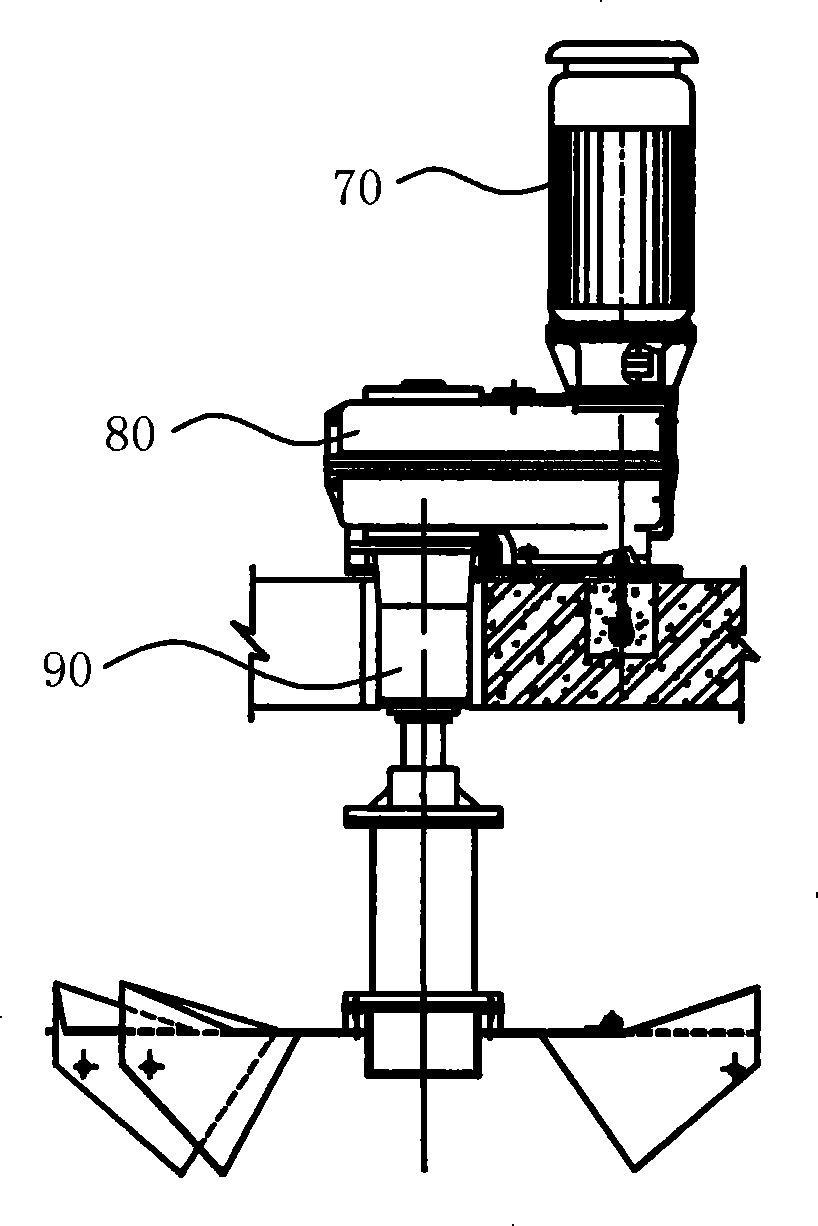

[0009] An aerator impeller, comprising a hollow shaft 40, the second plate body 20 and / or the third plate body 30 are evenly spaced along the circumferential direction of the hollow shaft 40, the plate surface of the second plate body 20 and the axis of the hollow shaft 40 To a parallel and complete plate surface, the included angle between the plate surface of the third plate body 30 and the axial direction of the hollow shaft 40 is less than 90°. Arranging the second plate body 20 or the third plate body 30 independently on the circumferential direction of the hollow shaft 40 can stir up the water body and realize oxygenation. In the present invention, the combination of the second plate body 20 and the third plate body 30 is adopted. way, to ensure that more water can be stirred up and the oxygenation capacity can be improved.

[0010] combine figure 1 , 2 , the outer peripheral surface of the hollow shaft 40 is provided with a first plate body 10 whose plate surface is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com