Oil balancing system of reciprocating oil isolation membrane pump fluid end

A technology of diaphragm pump and liquid end, which is applied in variable capacity pump components, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as pump failure, wear, and increased operating costs, and achieve improved The effect of service life, lower working temperature and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

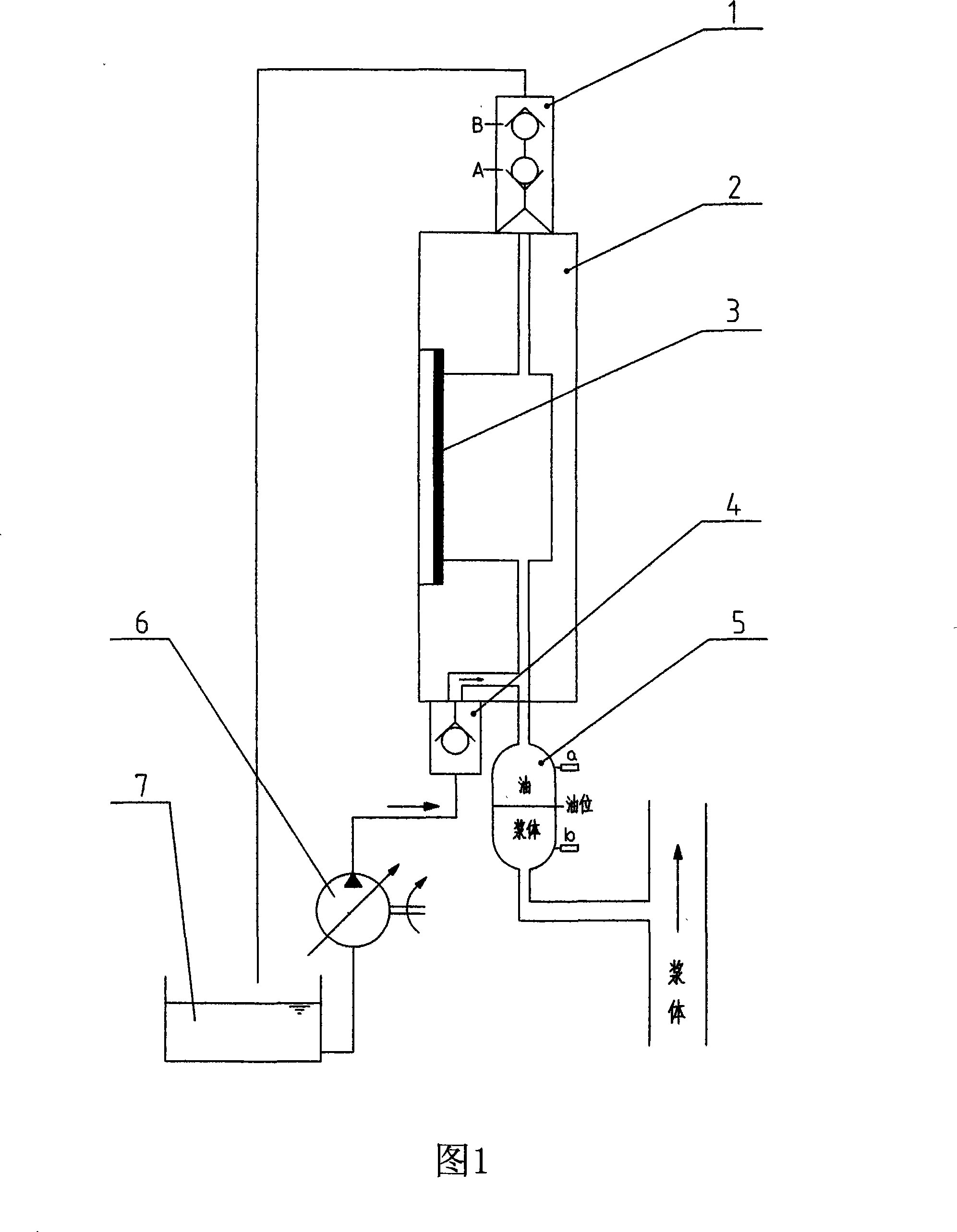

[0015] As shown in Figure 1, the air release valve 1 is located at the upper end of the cylinder body 2, the diaphragm 3 is located at the left side of the cylinder body 2, and the charge valve 4 is located at the lower end of the cylinder body 2, which is connected to the oil charge pump through pipelines and communicated with the oil circuit in the cylinder body , The cylinder body 2 is connected with the flow-passing parts through the oil isolation tank 5, the upper part of the oil isolation tank 5 is oil, the lower part is slurry, the oil level moves up and down continuously, and the upper and lower contacts a and b are set at the upper and lower limit positions of the oil level. When gas is generated at the top of the cylinder, a small amount of gas overflows from one-way valve A, one-way valve A closes, one-way valve B opens, and the gas is released from the release valve. The oil in the oil isolation tank 5 constantly flows away with the flowing slurry, the oil in the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com