Shifting mechanism

A gear shifting mechanism and forward gear technology, applied in the field of vehicle transmission, can solve problems such as inability to realize reverse gear and neutral gear, discontinuity of gear positions, and inability to realize smooth gear shifting, etc., to achieve convenient space layout, stable and reliable transmission, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

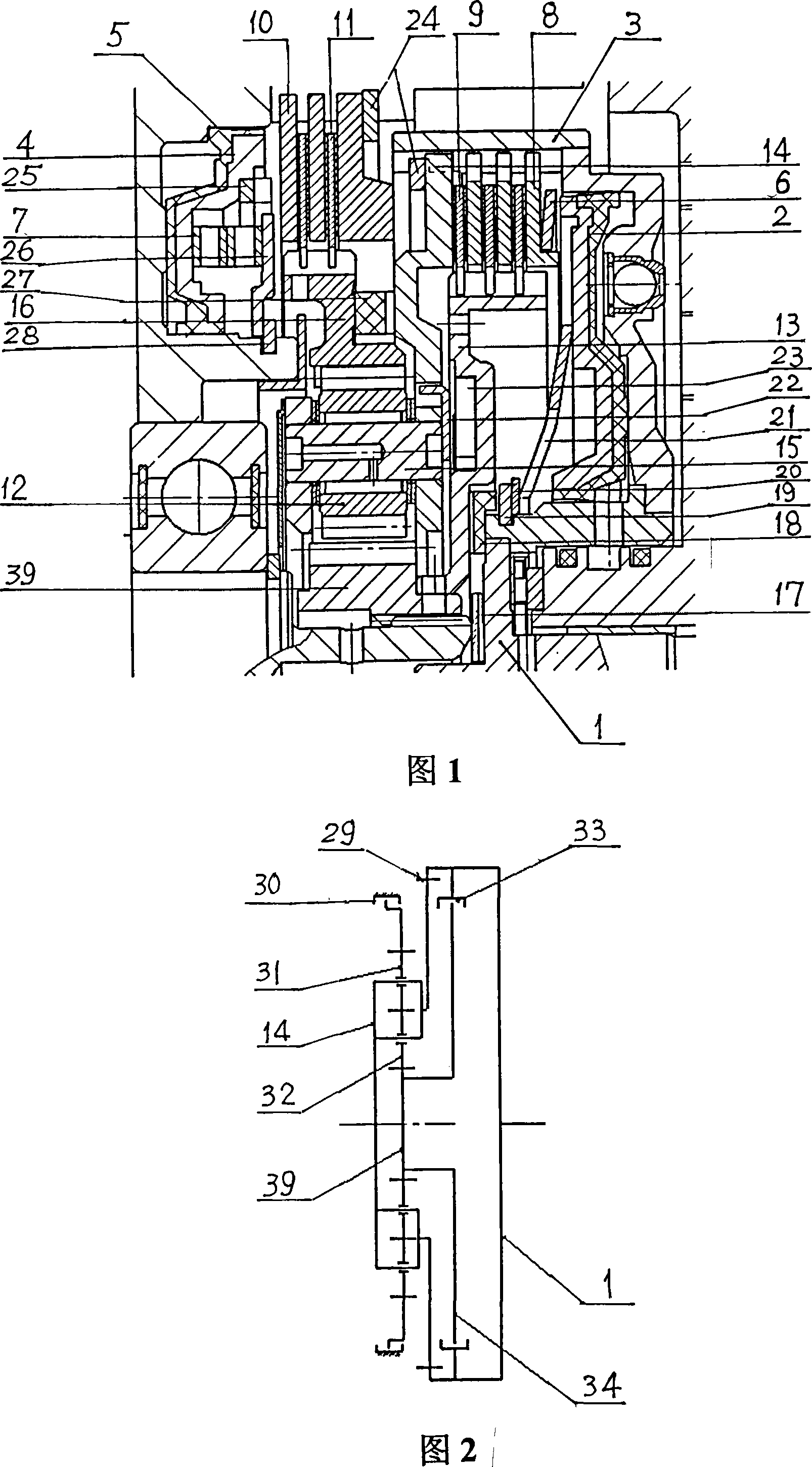

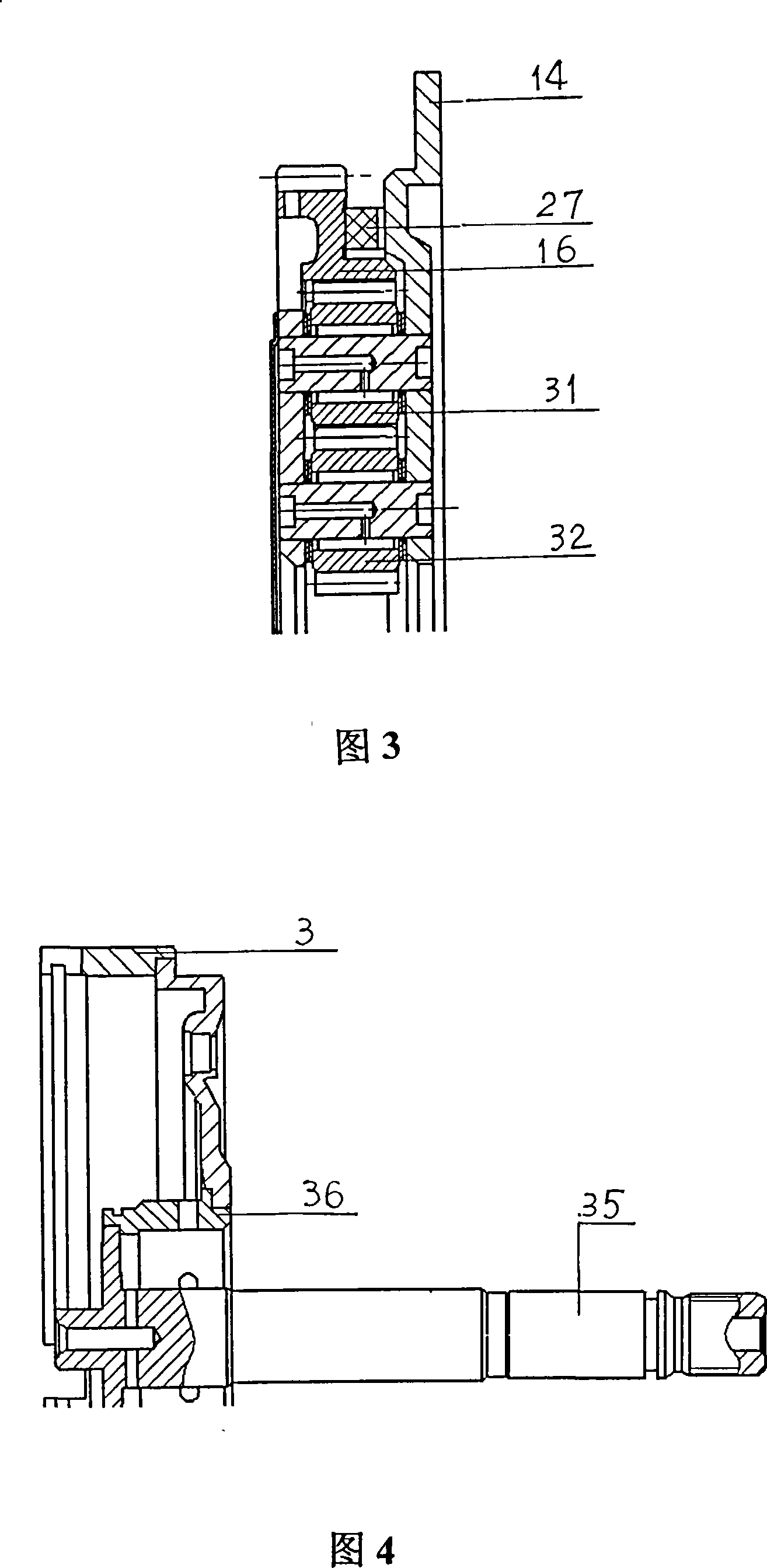

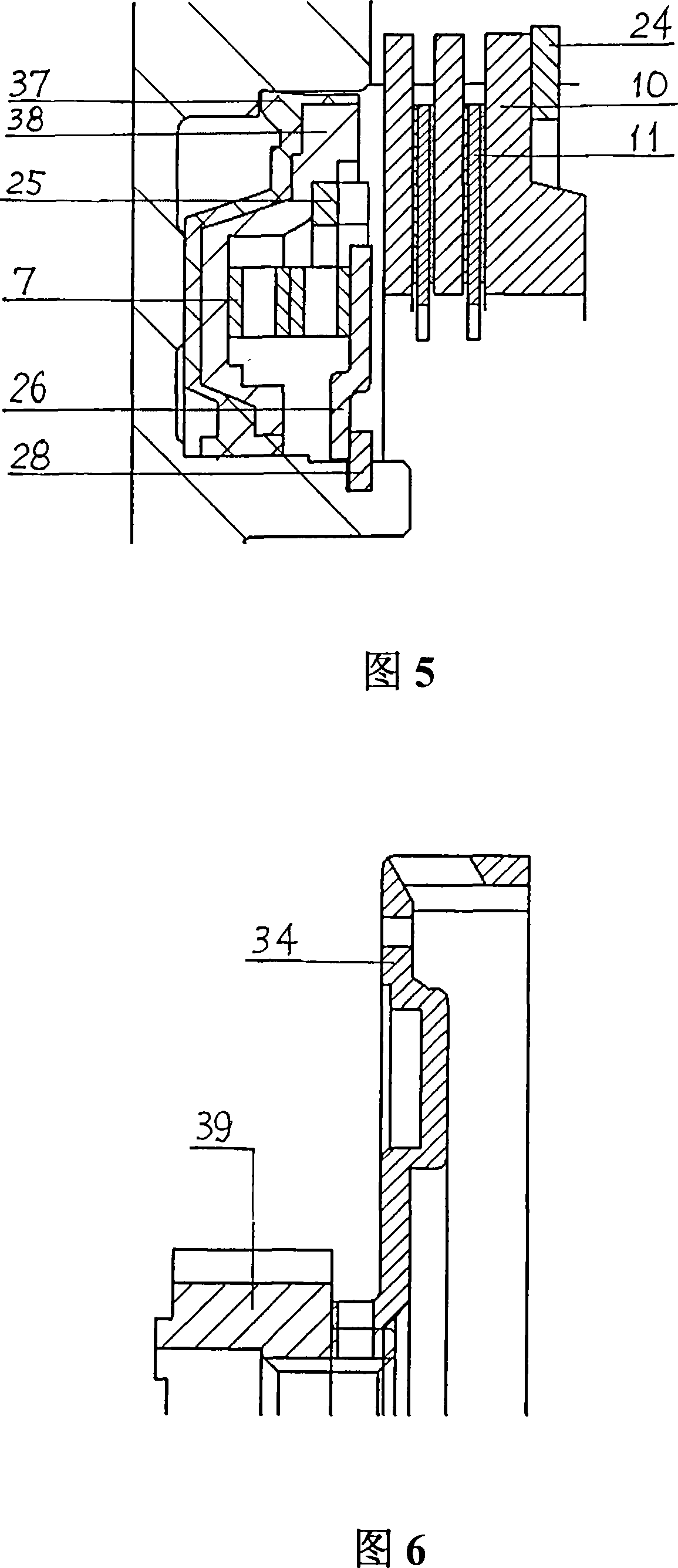

[0033] Referring to Fig. 1, Fig. 2, shift mechanism of the present invention is by input shaft weldment 1, forward gear piston 2, forward gear oil cylinder 3, reverse gear piston 4, reverse gear oil cylinder 5, return spring 6, compound spring 7, successively Stacked forward gear clutch steel plate 8, friction plate 9, reverse clutch steel plate 10, friction plate 11, planetary mechanism assembly 12 and sun gear welding piece 13; planetary mechanism assembly 12 includes planet carrier 14, planet Wheel 15, sun gear ring gear 16, and planet carrier 14 are located between the sun gear welded part 13 and sun gear ring gear 16. The forward gear clutch steel plate 8 and the planet carrier 14 are connected to the input shaft welded part 1 through splines respectively. , the forward clutch friction plate 9 is splined to the sun gear welding piece 13, the reverse clutch steel plate 10 is splined to the CVT housing, and the reverse clutch friction plate 11 is connected to the sun gear ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com