Assembly type ground radiation heating installation

A technology for ground radiation and heating devices, which is applied in hot water central heating systems, heating methods, and household heating, etc., can solve the problems of increased manufacturing costs of heating devices, reduced heat dissipation capacity of coils, and difficulty in reaching the temperature in winter. The effect of reducing the laying area, reducing heat energy loss, improving heat transfer efficiency and heat energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

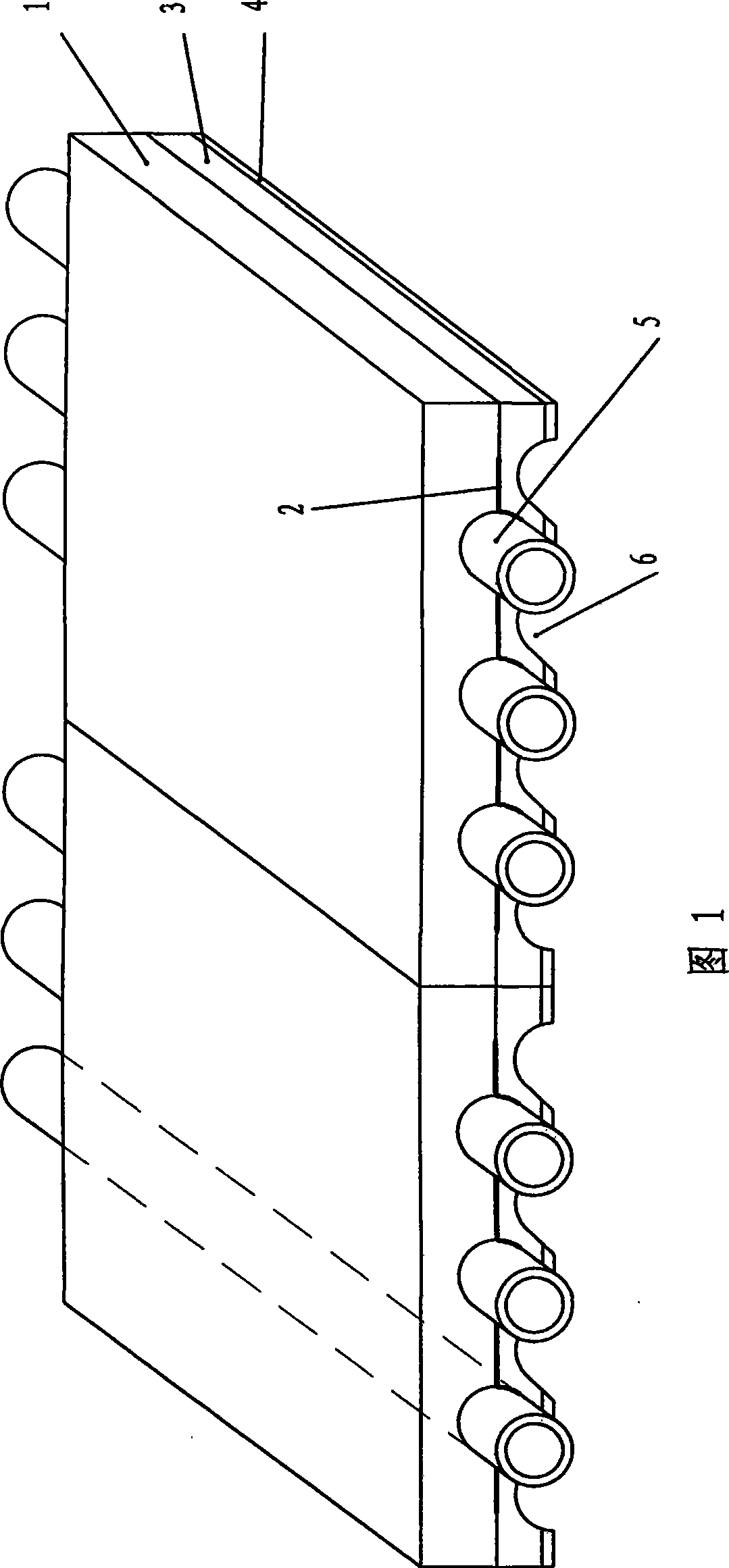

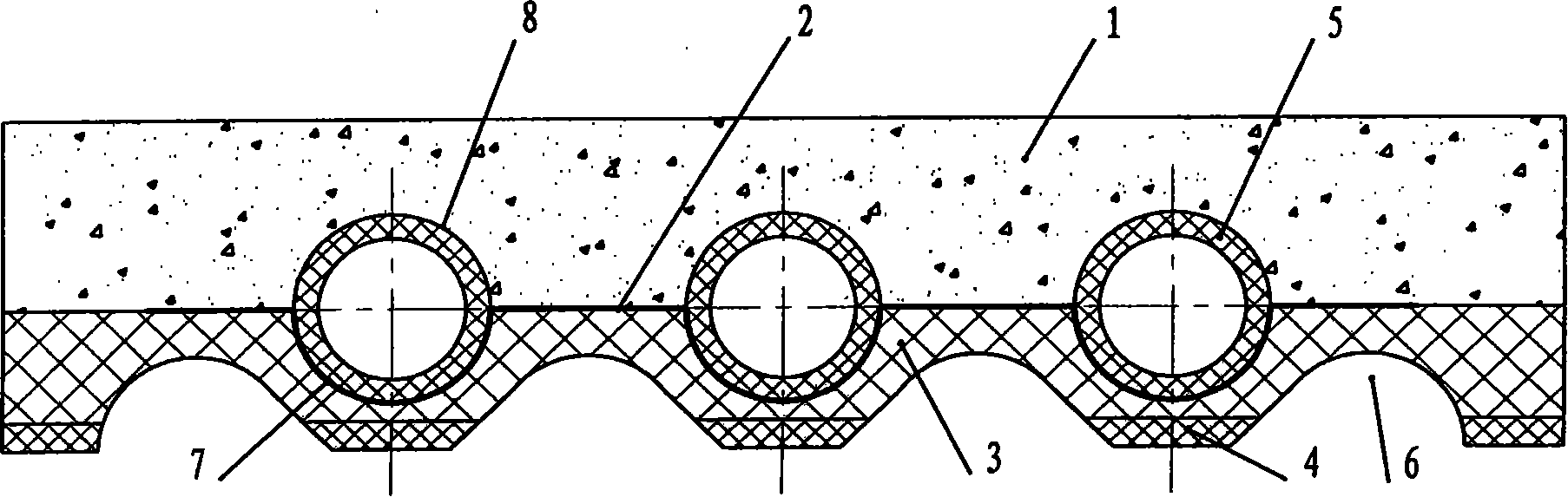

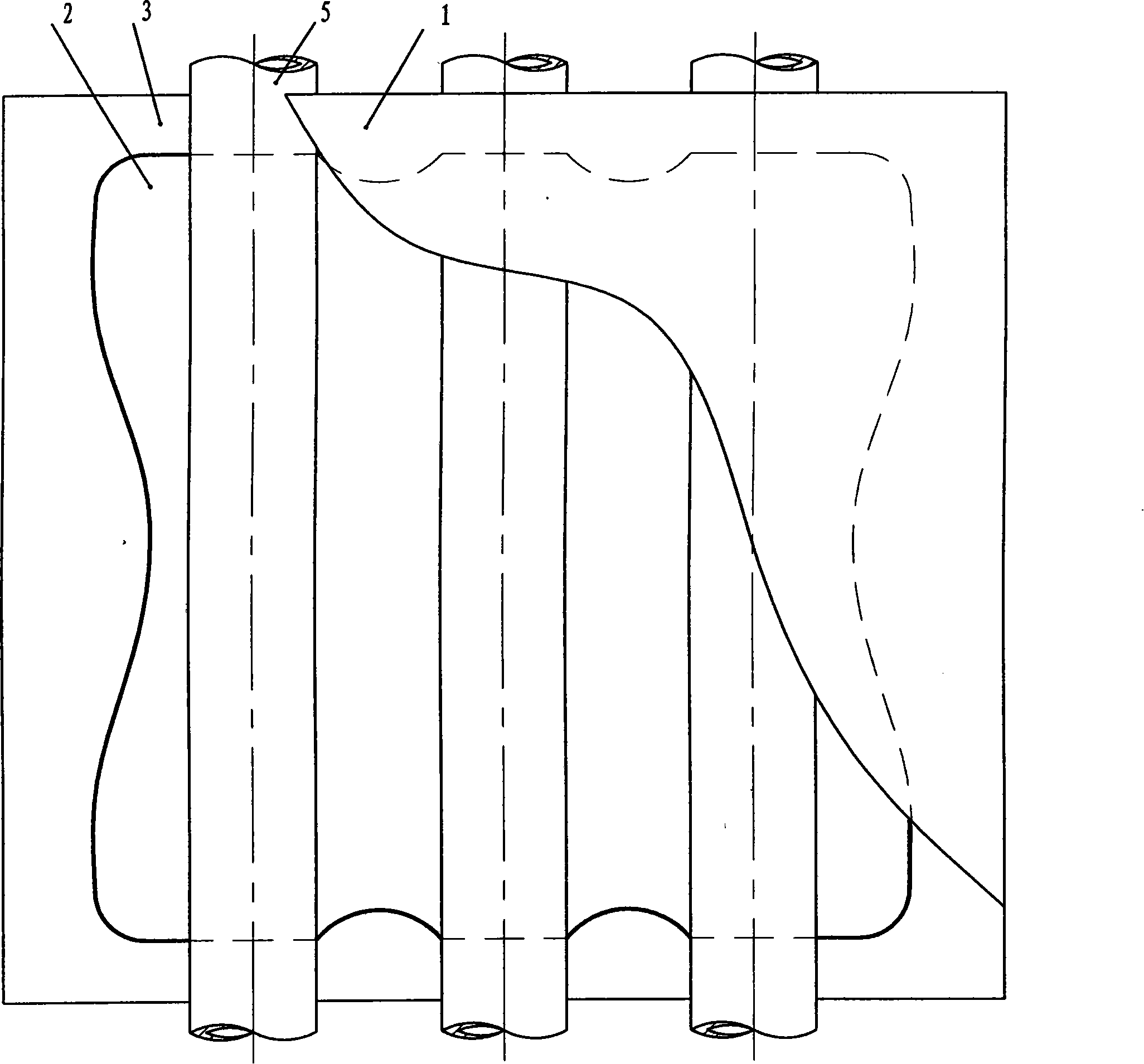

[0018] As shown in Figure 1, the assembled floor radiation heating device of the present invention includes several heat insulating boards 3 laid in horizontal rows and vertical columns, and several heat insulating boards 3 are laid in horizontal rows and vertical columns above the heat insulating boards 3. Radiation template 1, Figure 1 only schematically draws two sets of assembled floors, and the actual number of assembled floors can be determined according to the area of the room. Between the heat radiation template 1 and the heat insulation board 3, there is a hot water pipe 5 connected end to end, the two ends of the hot water pipe 5 are connected to the heating device, and the lower surface of the heat insulation board 3 is provided with more than one heat insulation groove 6. The area of the opening of the heat insulation groove 6 is 70% of the area of the lower surface of the heat insulation board 3, and the area of the opening of the heat insulation groove 6 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com