Microphone module group

A technology of microphones and modules, applied in frequency/directional characteristic devices and other directions, can solve the problems of occupying space, reducing assembly efficiency, increasing the cost of microphone arrays, etc., and achieving the effect of reducing difficulty and preventing the reflection of sound waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

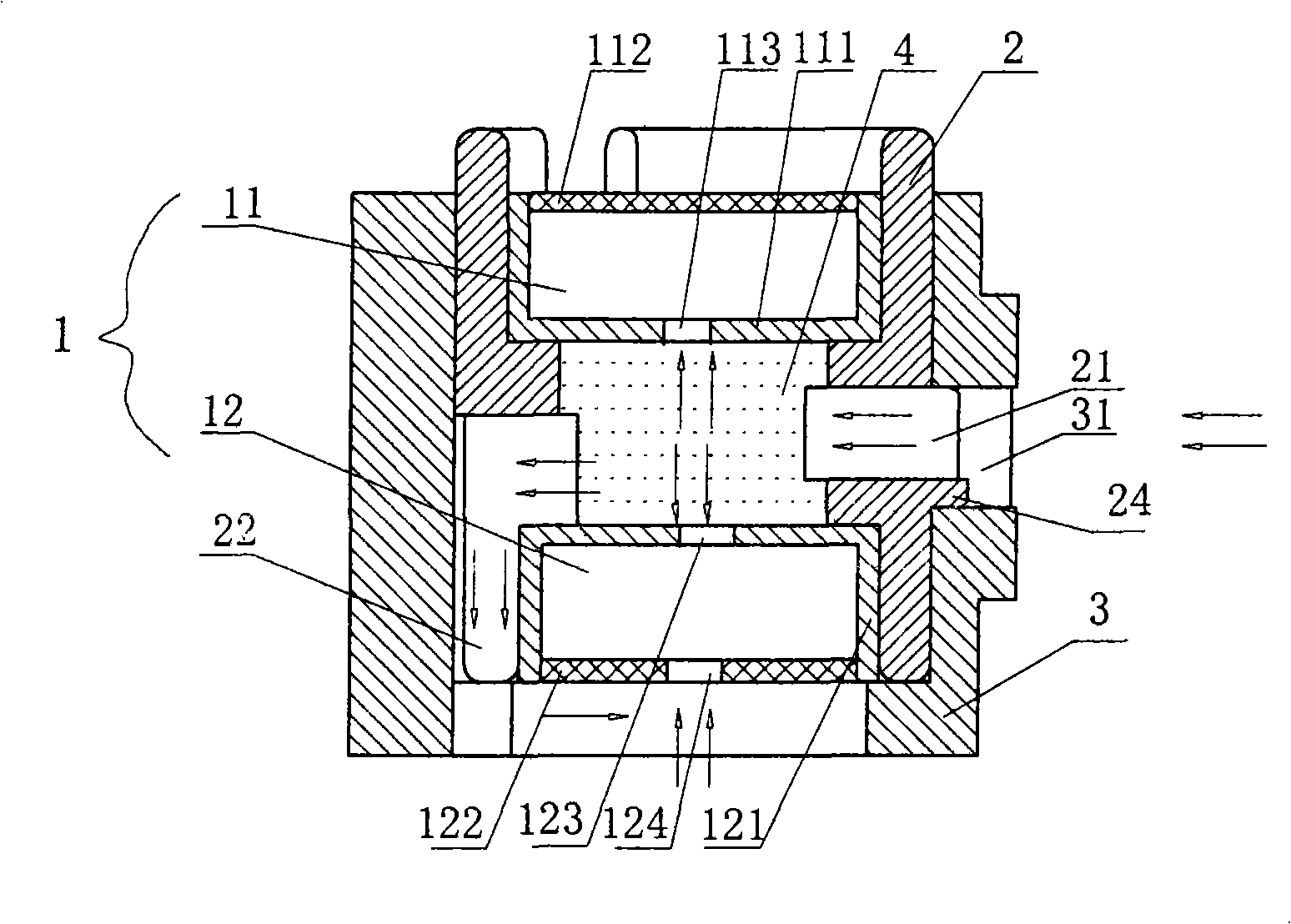

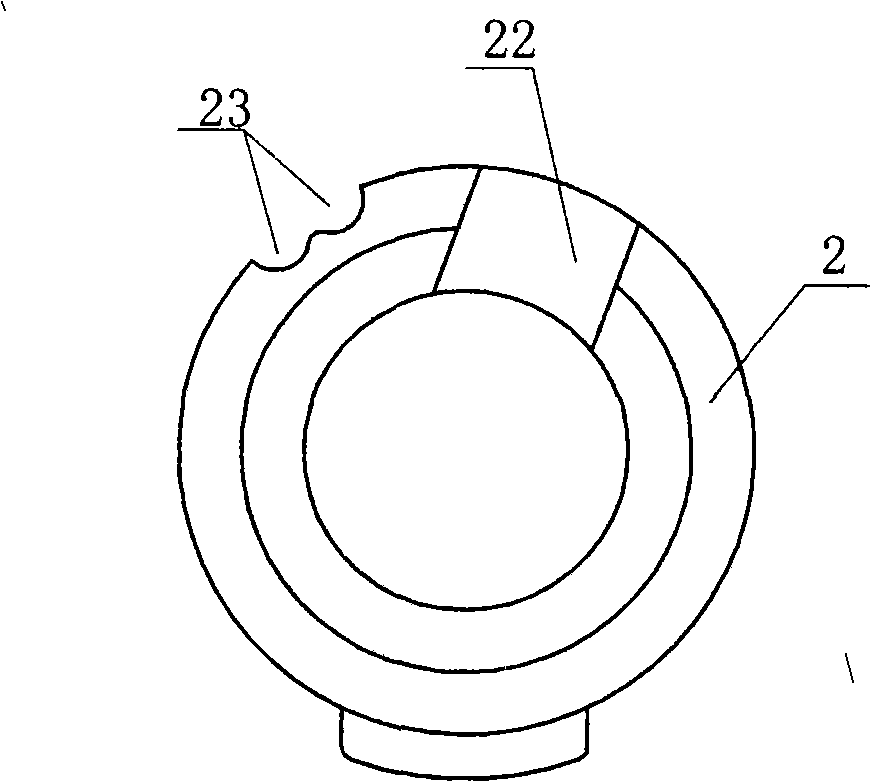

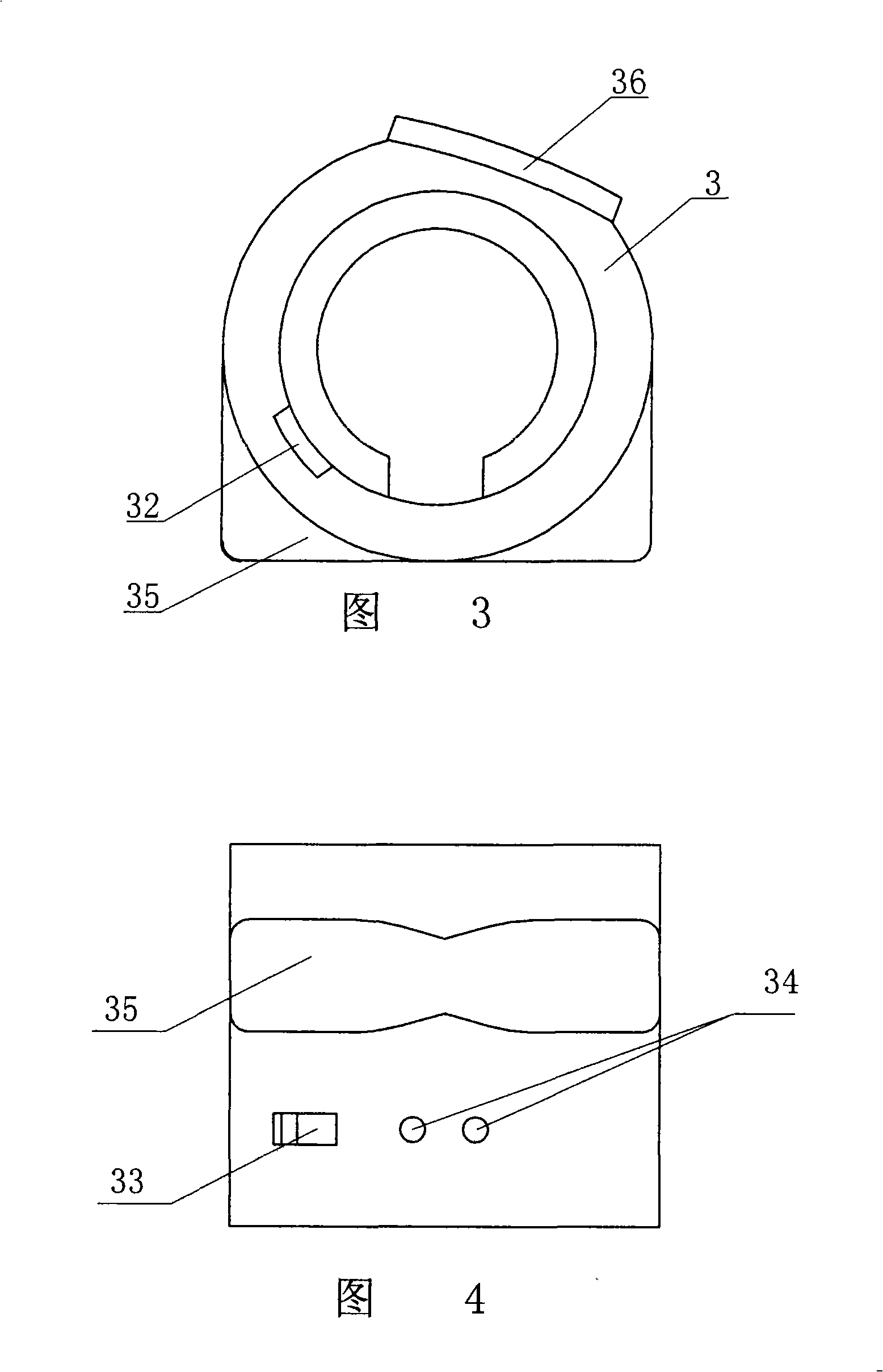

[0021] as attached figure 1 The microphone module shown in the figure consists of two microphone units 1, a plastic tube 2 with high hardness and a soft rubber cover 3. Both ends of the plastic tube 2 and the rubber cover 3 are open, and multiple microphone units 1 Pack into the plastic cylinder 2, and the rubber sleeve 3 is wrapped on the outside of the plastic cylinder 2. In this embodiment, both the plastic cylinder 2 and the rubber sleeve 3 are approximately cylindrical, and of course they can also be square columns or other column shapes. In this implementation case, the plastic cylinder 2 and the rubber sleeve 3 are independent of each other. Multiple microphone units 1 are first loaded into the plastic cylinder 2, and then the plastic cylinder 2 is loaded into the rubber sleeve 3. At the same time, the plastic cylinder 2 and the rubber sleeve 3 The microphone units can be pre-assembled by injection molding and the like, and the plurality of microphone units 1 are compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com