Motor-driven wheel driving apparatus

A wheel-driven, electric technology, applied in the direction of gear transmission, electromechanical devices, electric vehicles, etc., can solve the problems of limiting installation space and increasing space, and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

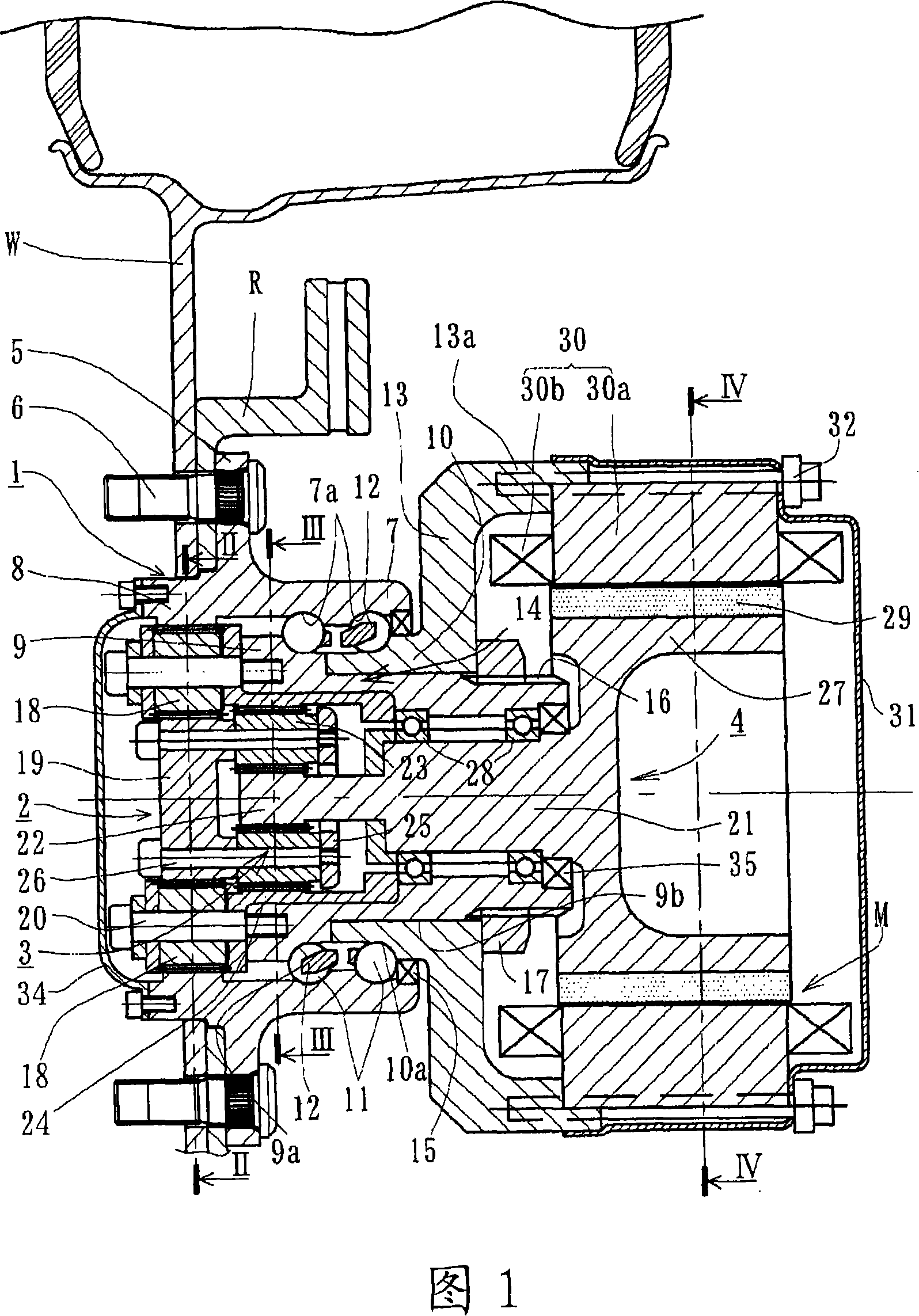

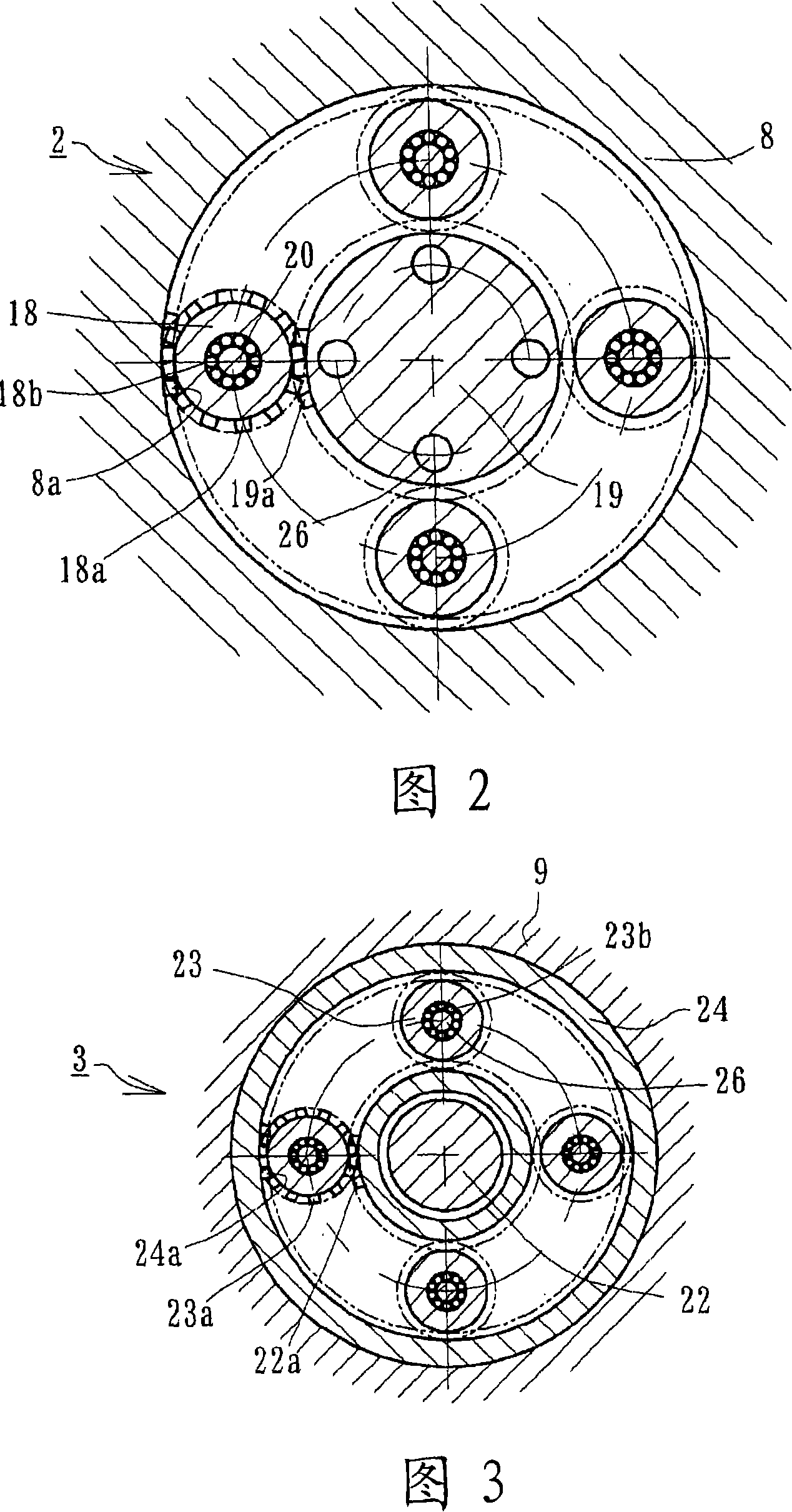

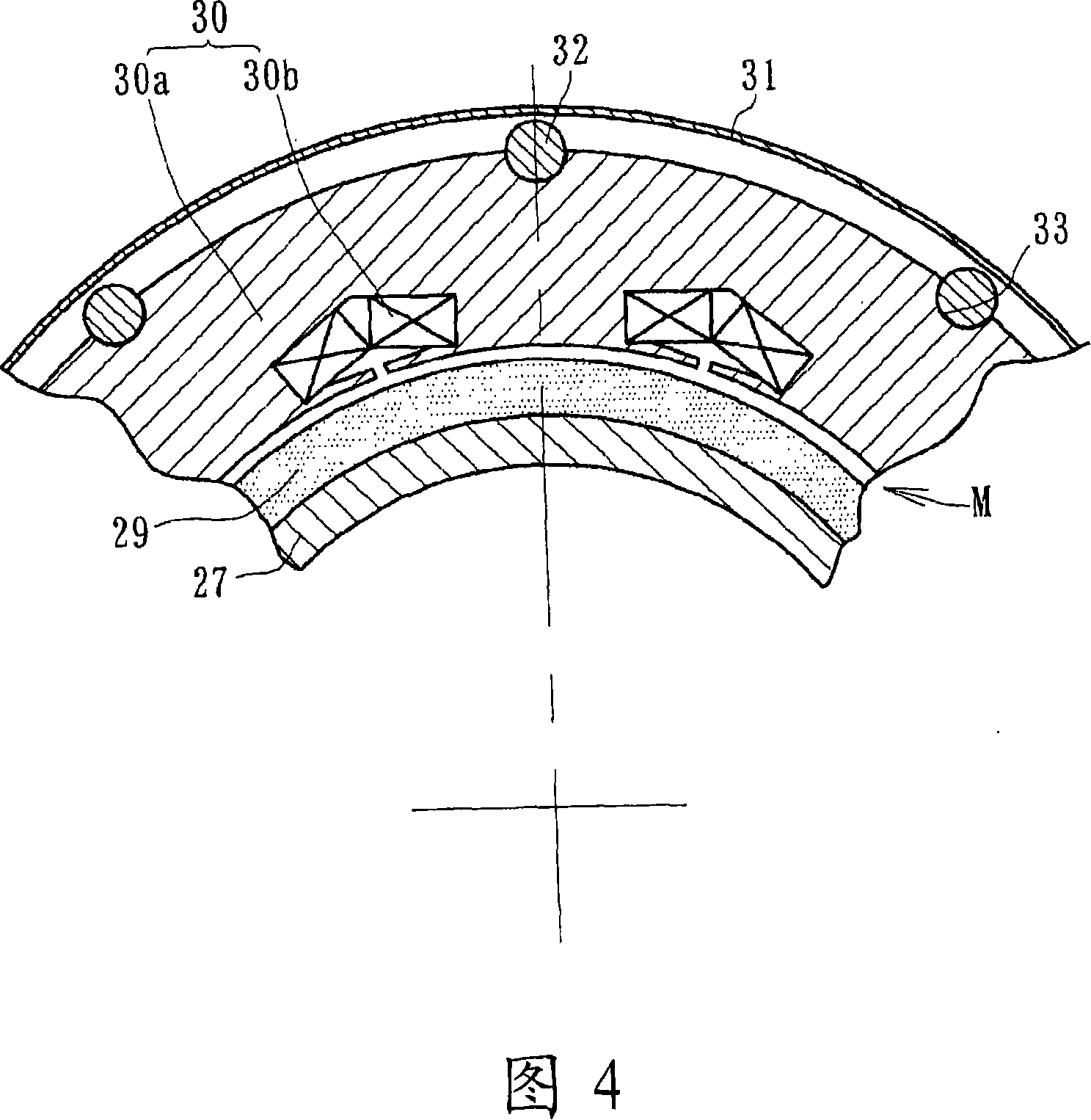

[0034] Fig. 1 is a longitudinal sectional view showing the first embodiment of the electric wheel drive device of the present invention, Fig. 2 is a cross-sectional view along the line II-II of Fig. 1 , and Fig. 3 is a cross-sectional view along the line III-III of Fig. 1 Cross-sectional view, Fig. 4 is a cross-sectional view along line IV-IV of Fig. 1 . In addition, in the following description, in the state mounted on the vehicle, the side closer to the vehicle outer side is referred to as the vehicle outer side (left side in the drawing), and the side closer to the center is referred to as the vehicle inner side (right side in the drawing). side).

[0035] The electric wheel drive device mainly includes: a wheel bearing 1; a first planetary reducer 2 disposed radially inside the wheel bearing 1; a second planetary reducer 3 connected to the first planetary...

Embodiment 2

[0052] Fig. 5 is a longitudinal sectional view showing a second embodiment of the electric wheel drive device of the present invention. Furthermore, this embodiment is only different in the structure of the planetary reducer in the first embodiment described above, more specifically, the structure of the first planetary reducer; Functional parts are denoted by the same reference numerals, and repeated explanations are omitted.

[0053] The first planetary reducer 2' constitutes a so-called planetary type planetary reducer, which is provided with: a first internal gear (output unit) 8' integrally formed with a first inner ring member 9' and formed with internal teeth 8a; four first planetary gears (planetary units) 18, which are formed with external teeth 18a meshing with the internal teeth 8a of the first internal gear 8', and perform planetary motion along the inner circumference of the first internal gear 8'; and A sun gear (input unit) 19 formed with external teeth 19 a me...

Embodiment 3

[0056] Fig. 6 is a longitudinal sectional view showing a third embodiment of the electric wheel drive device of the present invention. In addition, this embodiment is a modified example of the first embodiment described above, and is constituted by a one-stage planetary reducer. In addition, the same reference numerals are attached to the same members and the same parts or parts having the same functions as those in the embodiment described above, and overlapping descriptions will be omitted.

[0057] The planetary speed reducer in this electric wheel drive basically abolishes the second planetary speed reducer 3 in the first embodiment ( FIG. 1 ), and consists of the first planetary speed reducer 2 as one stage. This planetary reducer 38 constitutes a star-shaped planetary reducer in which the first internal gear 8 rotates by itself, and includes: a first internal gear (output unit) 8 integrally formed on the outer member 7 and formed with internal teeth 8a; a first planetar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com