Method for stopping water of earth wire and earth wire

A grounding cable and grounding terminal technology, which is applied in the direction of connecting/terminating cables, insulating cables, insulating conductors/cables, etc., can solve problems such as troublesome waterproofing operations, and achieve the effect of simple and easy waterproofing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

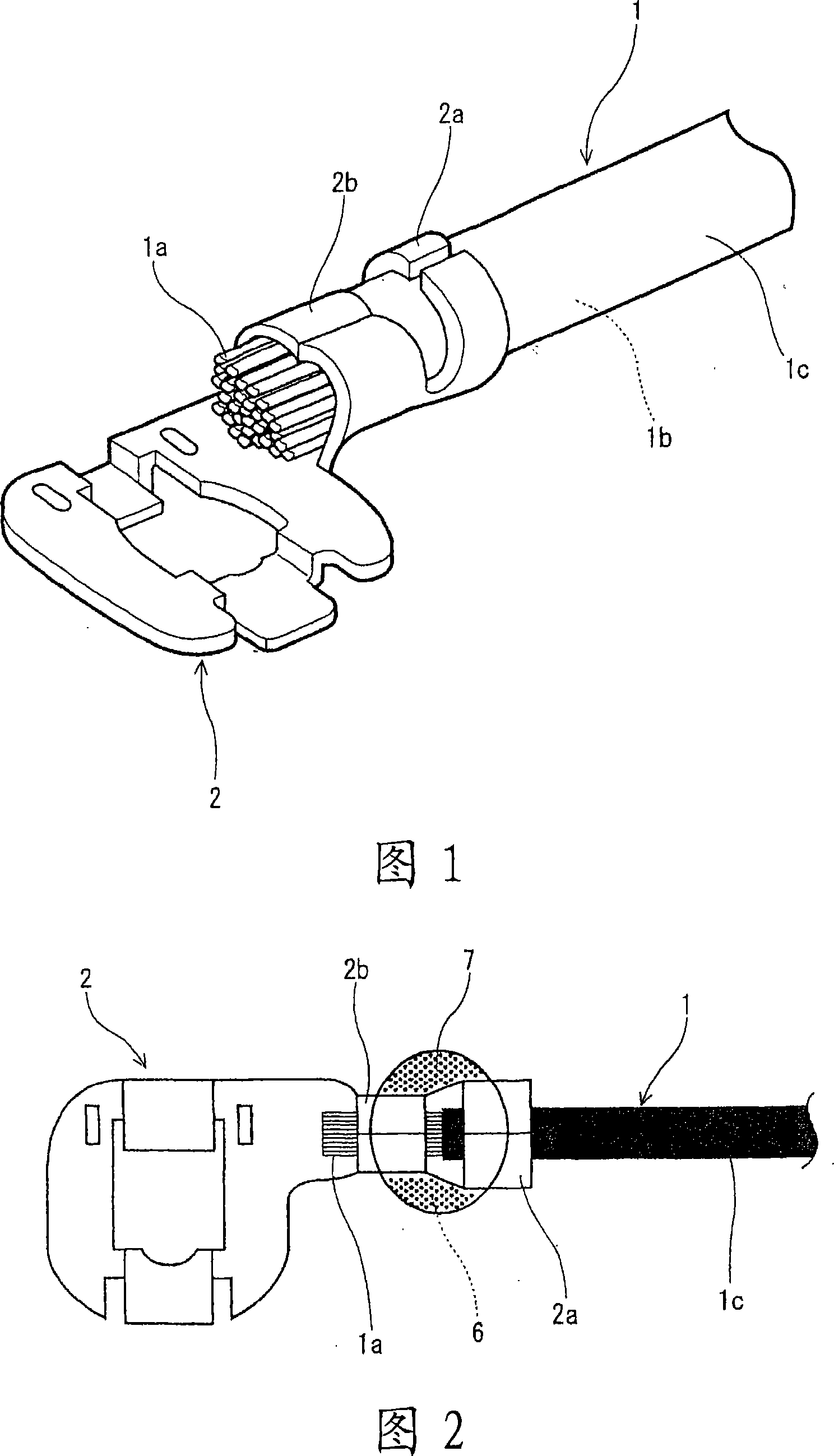

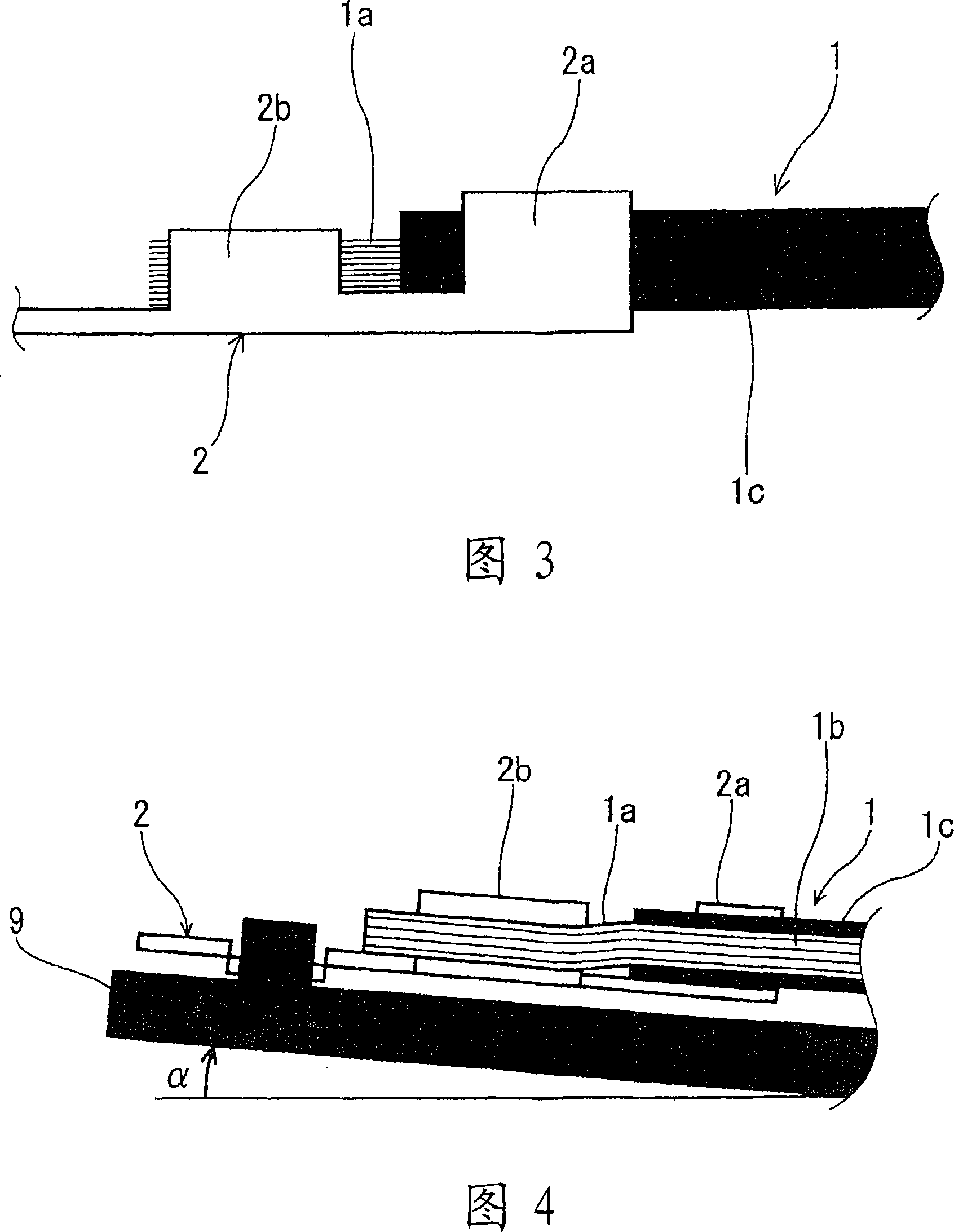

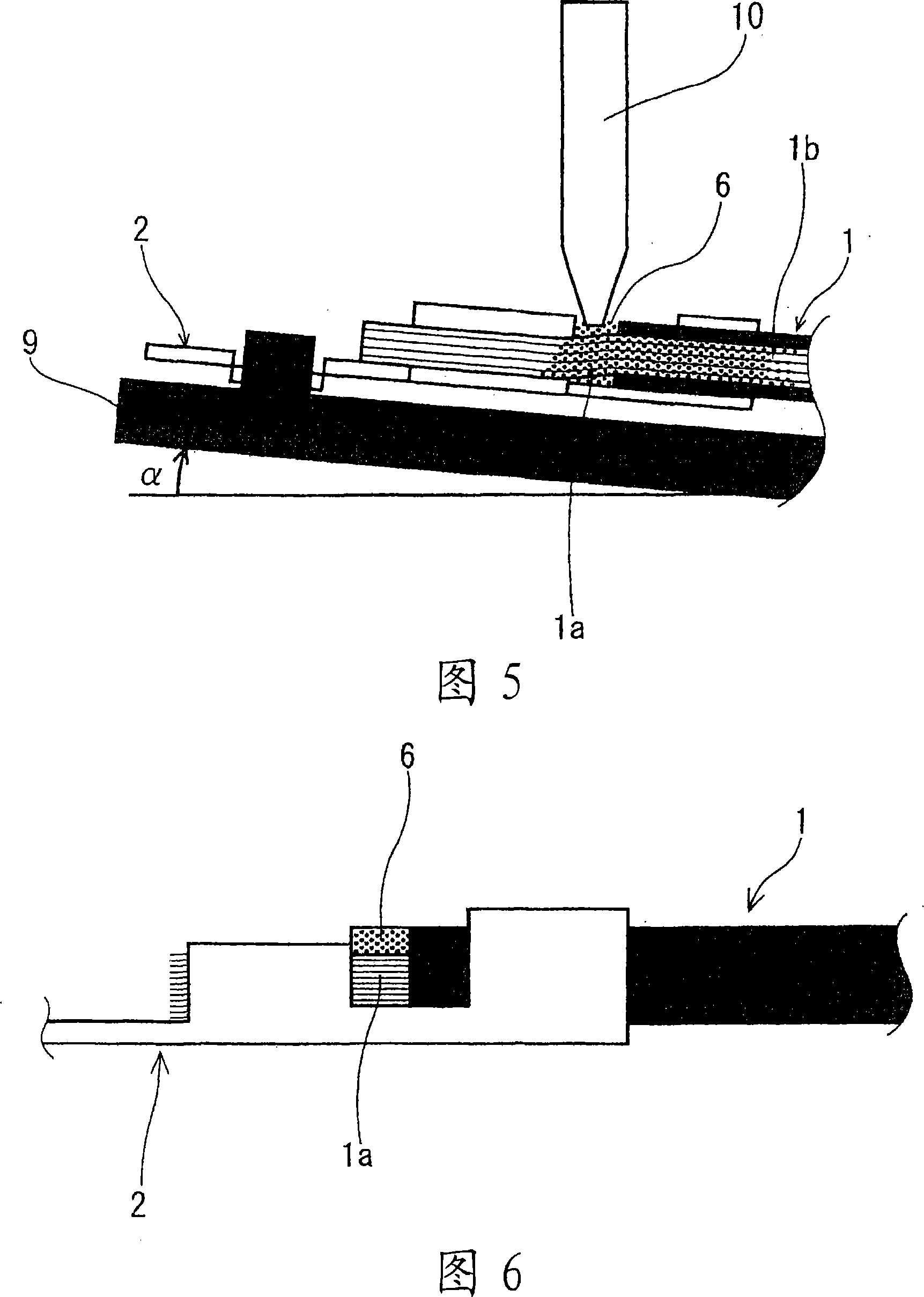

[0062] Next, Embodiment 1 of the present invention (representing the case of using an ultraviolet curing type first sealing agent) will be described.

[0063] The wire cross-sectional area is 0.5mm 2 and 1.25mm 2 A pair of ground cables are crimped on the ground terminal. Subsequently, a first sealant (ultraviolet curable type) having a viscosity of 15 mPa·s was delivered in a dropwise manner in an amount of 25 microliters. Then, the second sealant having a viscosity of 5000 mPa·s was delivered in a droplet manner in an amount of 10 microliters. UV irradiation conditions are set to 100mW / cm 2 ×70 seconds.

[0064] As a result, 200kPa (approximately 2kgf / cm 2 ) above the waterproof characteristics. Even after standing at a temperature of 110° C. for 200 hours, the waterproof property of 200 kPa was maintained. The suction height of the first sealant was 20 mm for each ground cable.

Embodiment approach 2

[0066] Next, Embodiment 2 of the present invention (representing a case where a photocurable instant adhesive is used as the first sealing agent) will be described.

[0067] The wire cross-sectional area is 0.5mm 2 and 1.25mm 2 A pair of ground cables are crimped on the ground terminal. Then, 25 microliters of the first sealant (light-hardening type instant adhesive) having a viscosity of 15 mPa·s was delivered in drops. Then, 10 microliters of a second sealing agent (light-curing type instant adhesive) having a viscosity of 5000 mPa·s was delivered in drops. The light irradiation condition is set to 100mW / cm 2 (365nm) x 70 seconds.

[0068] As a result, 200kPa (approximately 2kgf / cm 2 ) above waterproof properties, even after 200 hours at a temperature of 110°C, the waterproof properties of 200kPa are still maintained. The suction height of the first sealant was 20 mm for each ground cable.

Embodiment approach 3

[0070] Next, Embodiment 3 of the present invention (representing the case of using a photocurable and thermosetting adhesive as the first sealing agent) will be described.

[0071] The wire cross-sectional area is 0.5mm 2 , 1.25mm 2 A pair of ground cables are crimped on the ground terminal. Subsequently, a first sealant (light-curing and thermosetting adhesive) having a viscosity of 200 mPa·s was delivered in a dropwise manner in an amount of 15 microliters. Next, perform 100mW / cm 2 (365 nm) x 70 seconds of light irradiation, and then thermally hardened at 80° C. for 1 hour.

[0072] As a result, 200kPa (approximately 2kgf / cm 2 ) above the waterproof characteristics. Even after standing at a temperature of 120°C for 100 hours, the waterproof property of 200kPa was maintained. The suction height of the first sealant was 5 mm for each ground cable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com